Liquefaction process method and device capable of adjusting carbon dioxide concentration and separating carbon dioxide from critical biogas

A carbon dioxide and process device technology, applied in the petroleum industry, gas fuels, fuels, etc., can solve the problems of incompatibility between investment and recovery, high price, difficult promotion, etc., and achieve the effects of convenient operation, energy saving, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but this does not constitute a limitation to the protection scope of the claims of the present invention.

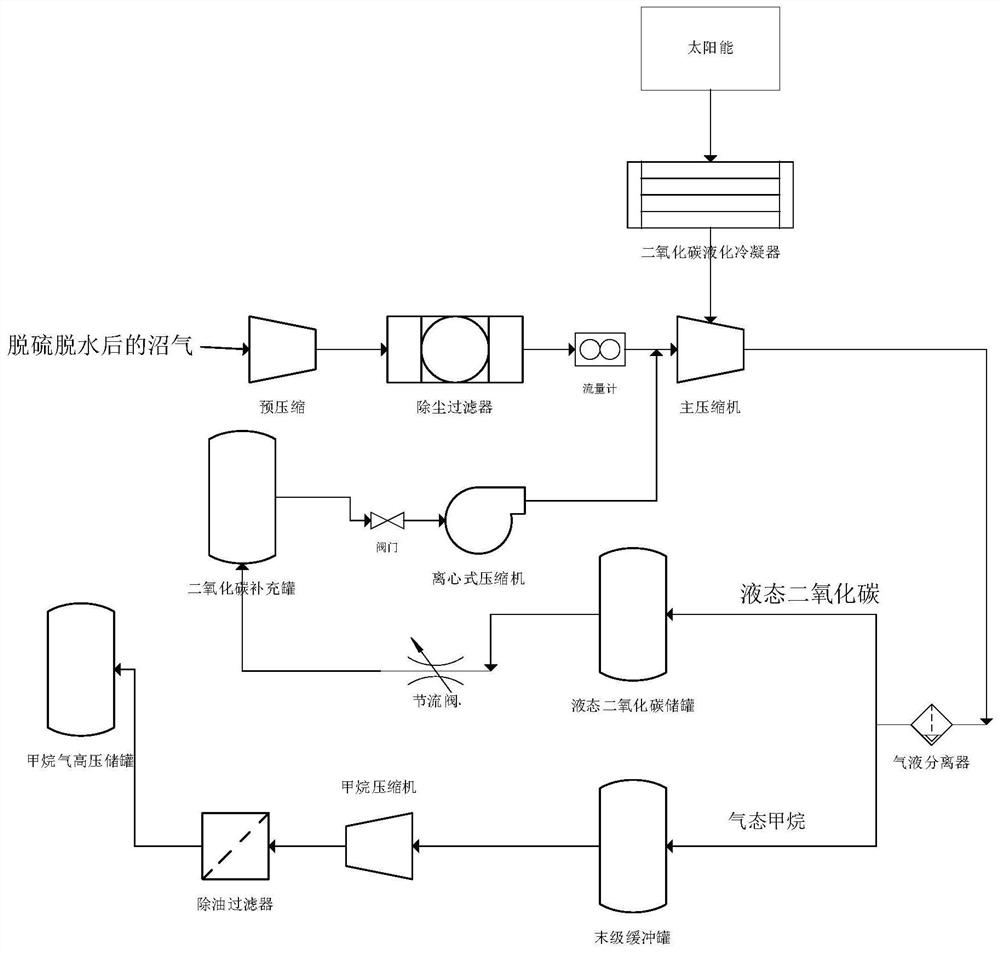

[0025] A liquefaction process method for separating carbon dioxide from critical biogas with adjustable carbon dioxide concentration, using such as figure 1 The shown device comprises the following process steps:

[0026] (1) The biogas is desulfurized and dehydrated pre-treated, and the pre-treated and purified biogas is input into the pre-compressor, and the biogas is pre-compressed to 2.5MPa. The biogas from the pre-compressor is dedusted by the dust filter, and then the flow meter is used Control the flow rate and send it to the main compressor. After the first, second, and third stages of pressurization in the main compressor, the pressure of the biogas increases to 25.0MPa. When the partial pressure of carbon dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com