Method and production system for removing spandex in waste polyester textiles

A technology for textiles and waste polyester, applied in the direction of products, educts, reagents, etc., can solve the problems of wastewater discharge, failure to meet performance requirements, large quantities, etc., and achieve the effect of short process flow and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

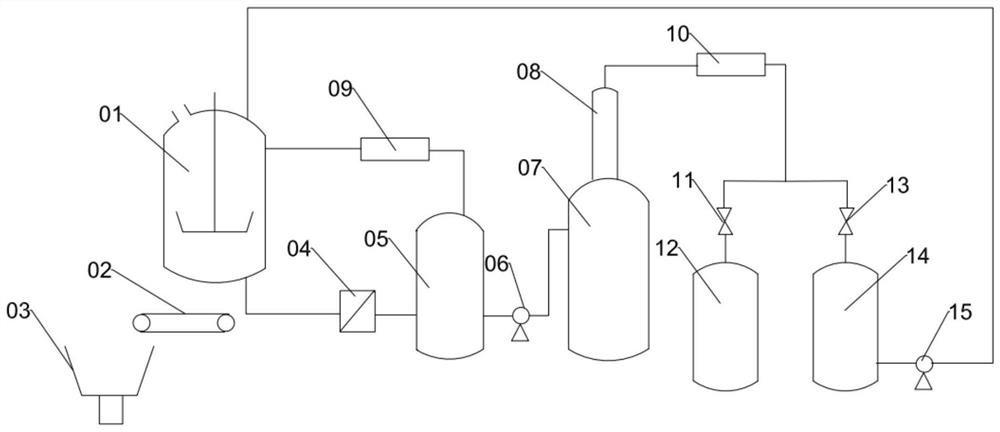

Method used

Image

Examples

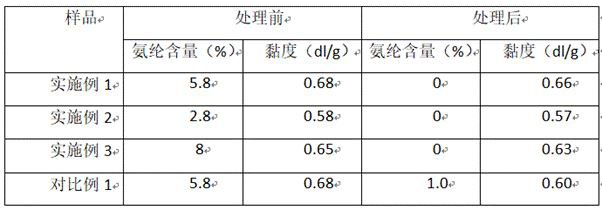

Embodiment 1

[0042] A kind of concrete production process of the method for removing spandex in waste polyester textiles is as follows:

[0043] The recovered polyester fabric containing 5.8% spandex is crushed, and the crushed fabric fragments are 1-5cm in length and 0.6-0.75g / cm in density 3 .

[0044] Put the crushed waste polyester fabric into the reactor 1, and inject the recovered N,N-dimethylacetamide (DMAC / DMA) solution into the reactor 1 through the feed pump 15, and the waste polyester textiles are mixed with N , The mass ratio of N-dimethylacetamide (DMAC / DMA) is 1:2, the reaction temperature is 70°C, the reaction time is 1.5h, and the stirring rate is 65rpm.

[0045] After the waste polyester textiles in the reactor 01 fully react with N,N-dimethylacetamide (DMAC / DMA), the reaction solution is discharged, filtered through the filter 04, and then recycled to the waste liquid tank 05.

[0046] After the reaction liquid is discharged, continue to heat the reactor 01, raise the t...

Embodiment 2

[0053] As described in Example 1, the difference is: this time the raw material is polyester foam material containing 2.8% spandex, and the mass ratio of waste polyester textiles to N,N-dimethylacetamide (DMAC / DMA) is 1 : 3, the reaction temperature is 70-80°C, and the reaction time is 2h.

Embodiment 3

[0055] As described in Example 1, the difference is: this time the raw material is polyester yarn containing 8% spandex, and the mass ratio of waste polyester textiles to N,N-dimethylacetamide (DMAC / DMA) is 1: 3. The reaction temperature is 70-80°C, and the reaction time is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com