Method for controlling curvature radius of large-curvature optical element

A technology of radius of curvature and optical components, which is applied in the directions of optical components, optics, and optical devices to reduce production time, improve efficiency, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

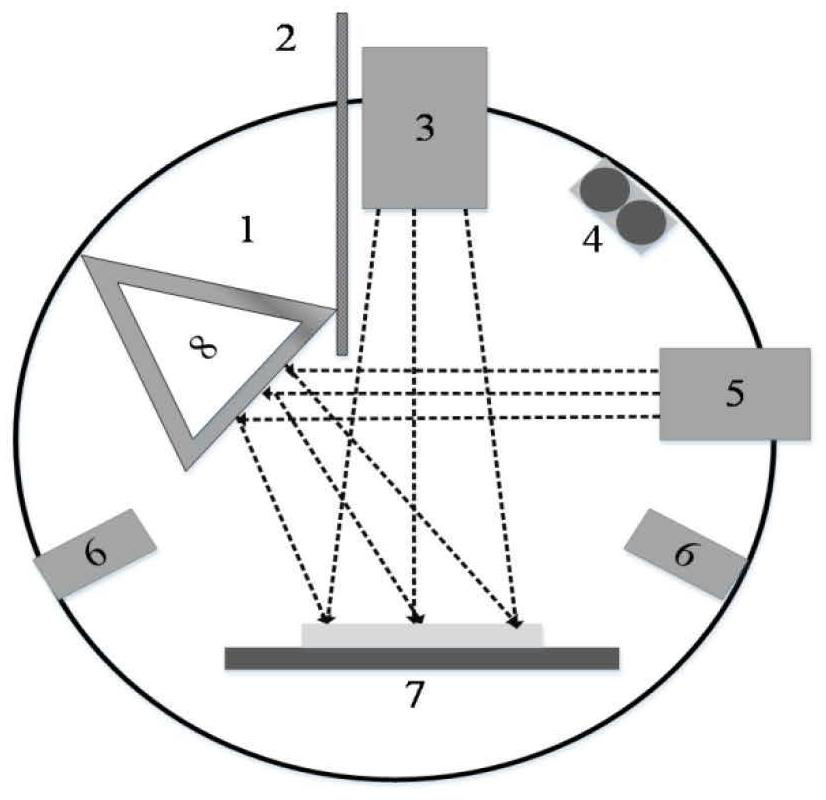

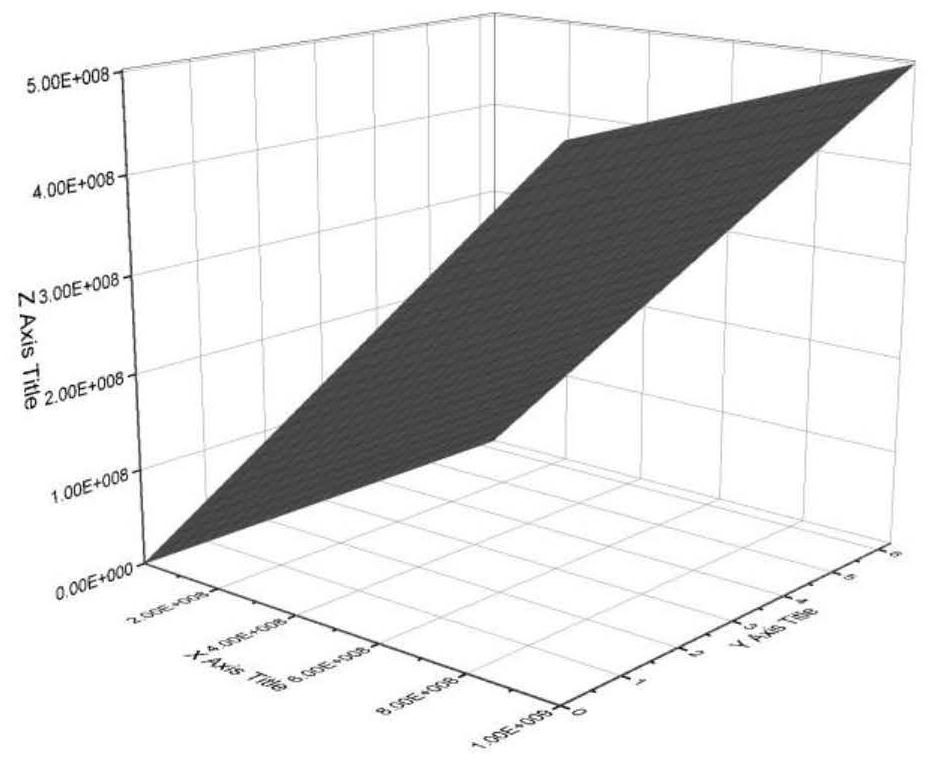

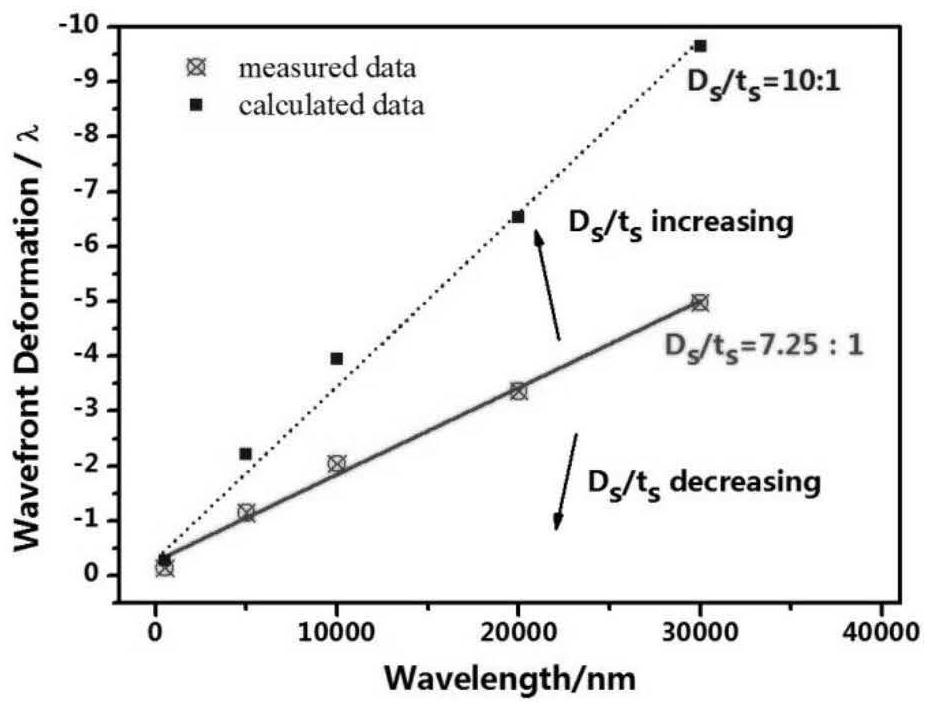

[0021] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In the process of film growth, the generation of film stress is inevitable. Membrane stress is usually divided into tensile stress and compressive stress. Usually, the films prepared by dual ion beam sputtering exhibit high compressive stress. The off-line calculation of membrane stress is as follows. attached figure 1 It is the relationship between the substrate diameter, the sagittal height and the radius of curvature and the control principle diagram of the radius of curvature. attached figure 1 As shown in (a), the relationship among substrate diameter, sagittal height and radius of curvature can be expressed as:

[0022]

[0023] whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com