Spiral anchor-anti-sinking plate-jacket composite foundation and construction method thereof

A composite foundation and anti-sinking plate technology, which is applied in basic structure engineering, sheet pile wall, wind power generation, etc., can solve the problems of increasing construction cost, increasing the amount of steel used for single-pile foundation at the bottom, increasing construction cost, difficulty and cycle, etc. , to achieve the effect of low installation cost, improved pullout bearing capacity, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

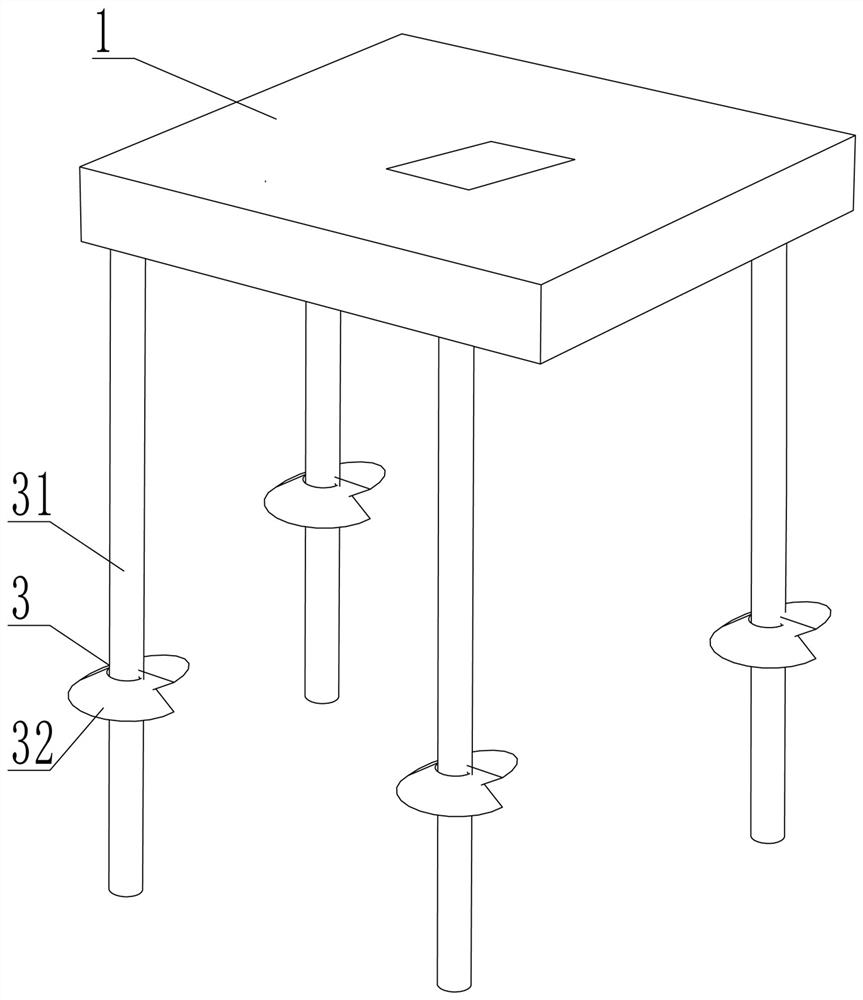

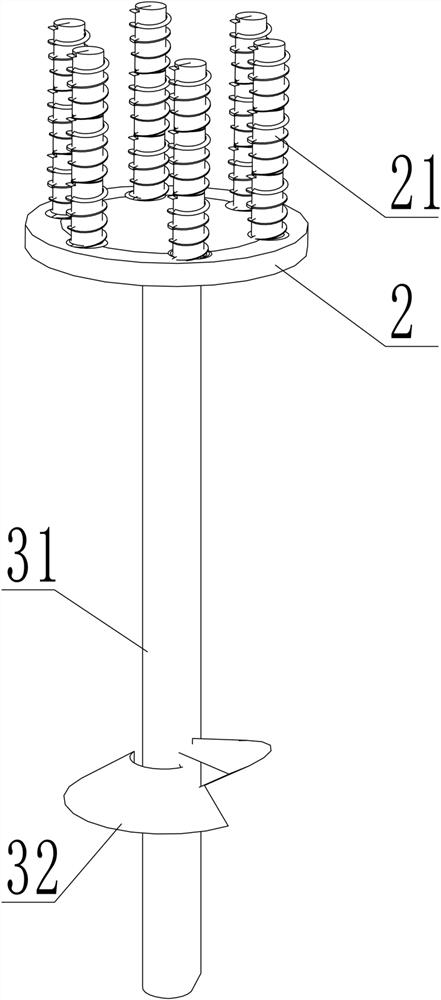

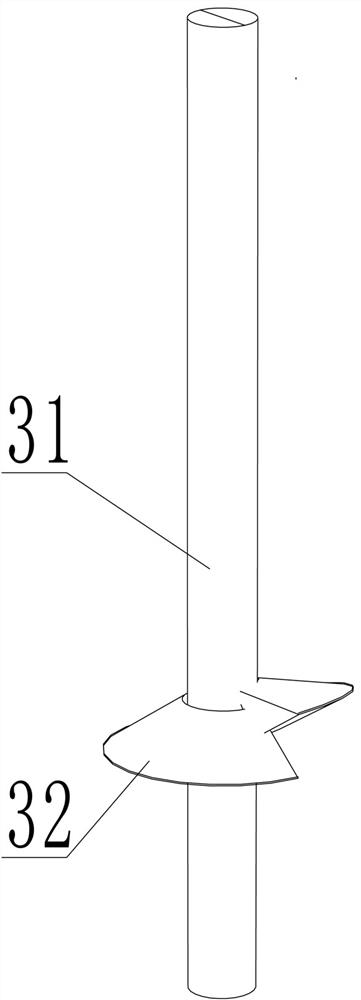

[0028] like Figure 1~Figure 6 Among them, a spiral anchor-anti-settling plate-jacket composite foundation, which includes an anti-settling plate 1, a flange 2, a spiral anchor 3 and a connecting block 4; the upper end of the spiral anchor 3 is connected to the lower side of the flange 2 , the flange 2 is connected to the anti-settling plate 1, and the connecting block 4 is connected to the anti-settling plate 1; multiple anti-settling plates 1 are arranged in an array, and a plurality of flanges 2 are arranged in an array on the lower side of each anti-settling plate 1, and each flange 2 is connected with at least one helical anchor 3.

[0029] Preferably, the dimensions of the screw anchor, the anti-settling plate, and the jacket connection block are selected according to the actual situation, and the material is steel.

[0030] In a preferred solution, the anti-settling plate 1 is a hollow box-shaped structure, and a plurality of connection holes penetrate the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com