Group matching method for reducing dynamic voltage difference of power type lithium battery pack

A lithium battery pack and dynamic differential pressure technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of high failure rate, poor cycle life and high cost of battery packs, and improve capacity conversion. efficiency, reducing production costs and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

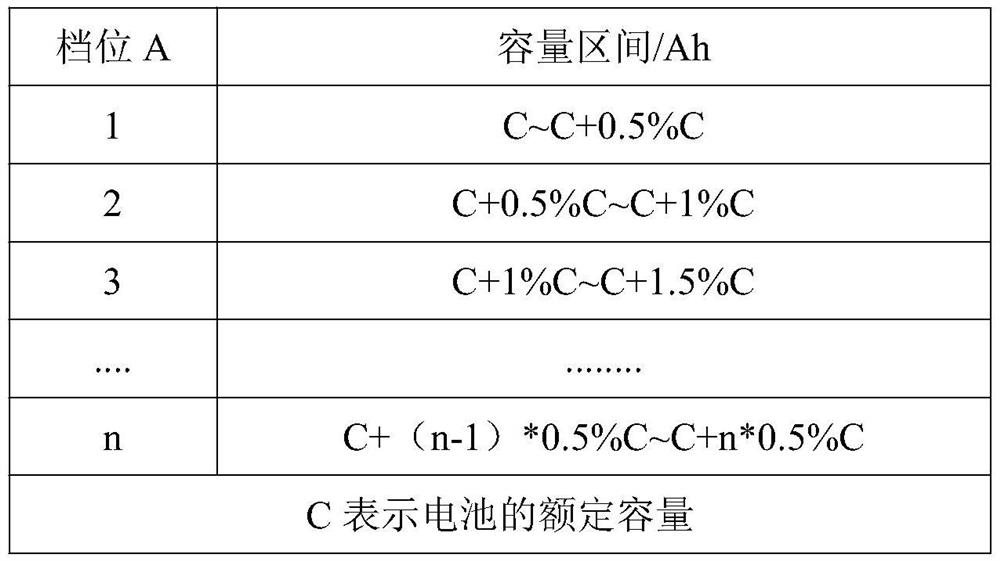

[0024] S1. For 30 lithium iron phosphate LiFePO 4 The capacity of the 50Ah single cell of the lithium battery is grouped once;

[0025] Gear A Capacity range / Ah 1 50Ah~50.25Ah 2 50.25Ah~50.5Ah 3 50.5Ah~50.75Ah 4 50.75Ah~51Ah 5 51Ah~51.25Ah

[0026] Based on the rated capacity of the battery of 50Ah, the capacity is divided into 5 gears. As shown above, the single cells are divided into corresponding gears according to the capacity division data, and the capacity at the maximum end of the interval is classified into the current gear;

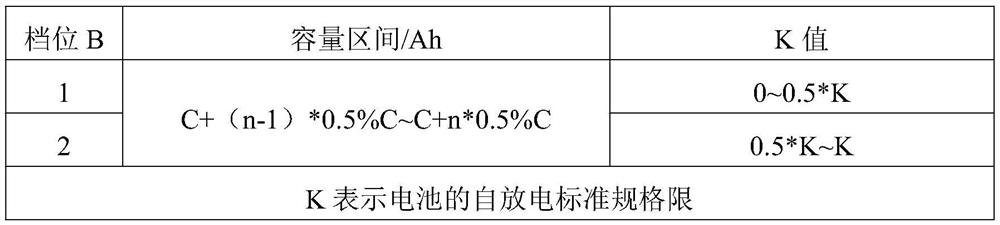

[0027] S2. Put the grouped single cells at room temperature and pressure for 15 days, then measure the K value, and carry out secondary grouping according to the K value;

[0028]

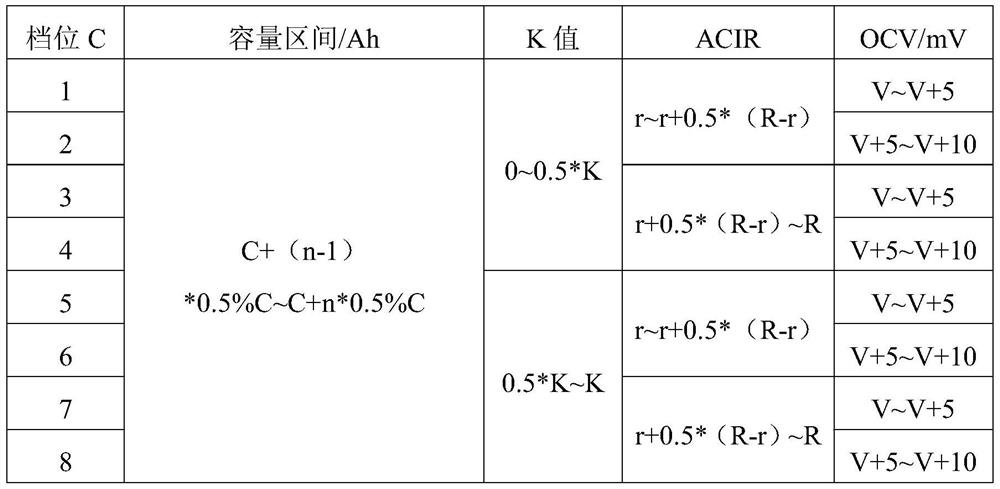

[0029] S3. Perform ACIR and OCV tests on the single cell of S2;

[0030] S4. Group the single cells of S3 three times according to ACIR and OCV;

[0031]

[0032]

[0033] Among them, r and R represent the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com