Highway tunnel sprayed concrete rebound material collecting and utilizing system

A technology for shotcrete and highway tunnels, applied in cleaning methods and appliances, lighting and heating equipment, grain processing, etc., can solve problems such as increasing recycling operations, reducing recycling efficiency, and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

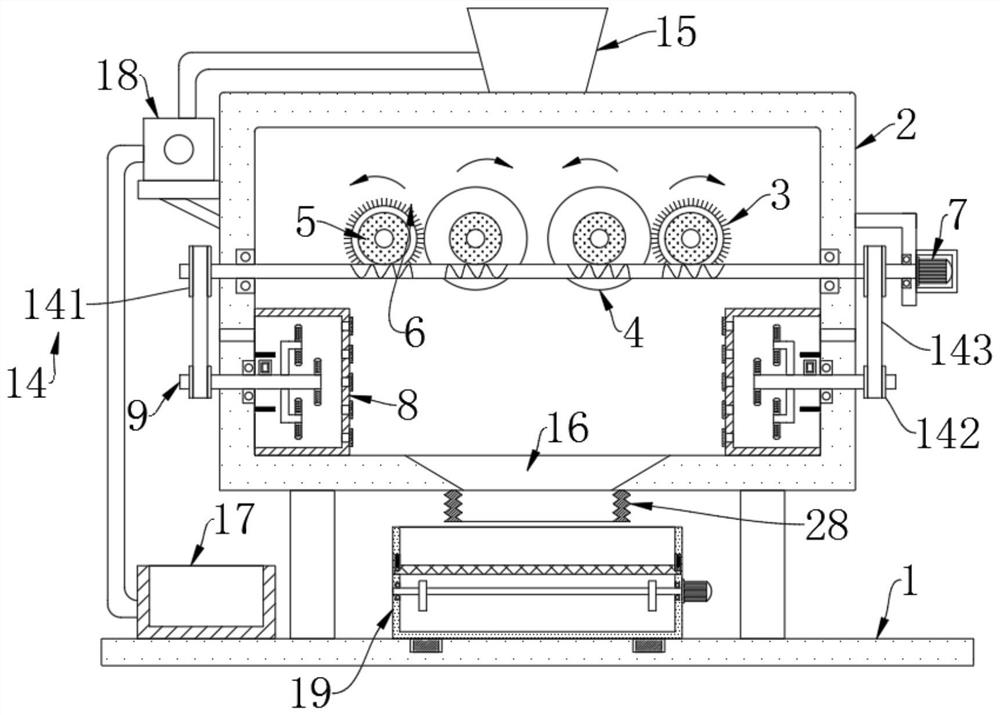

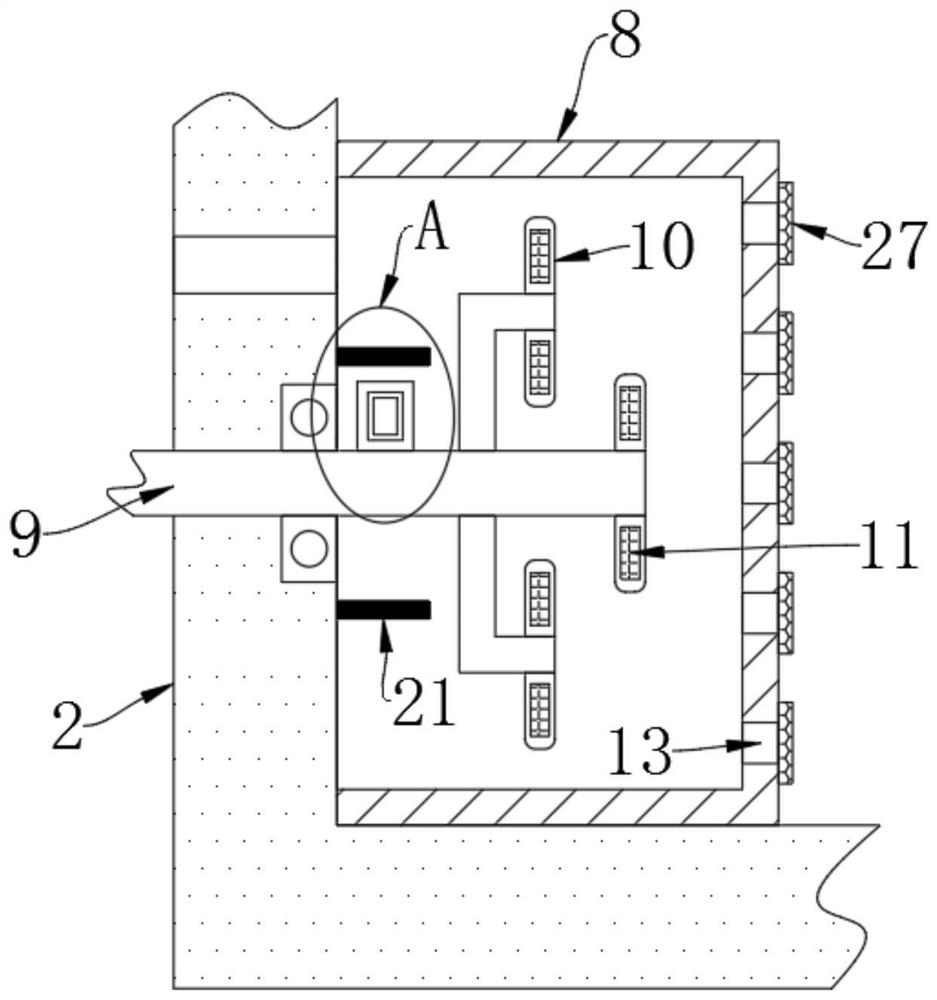

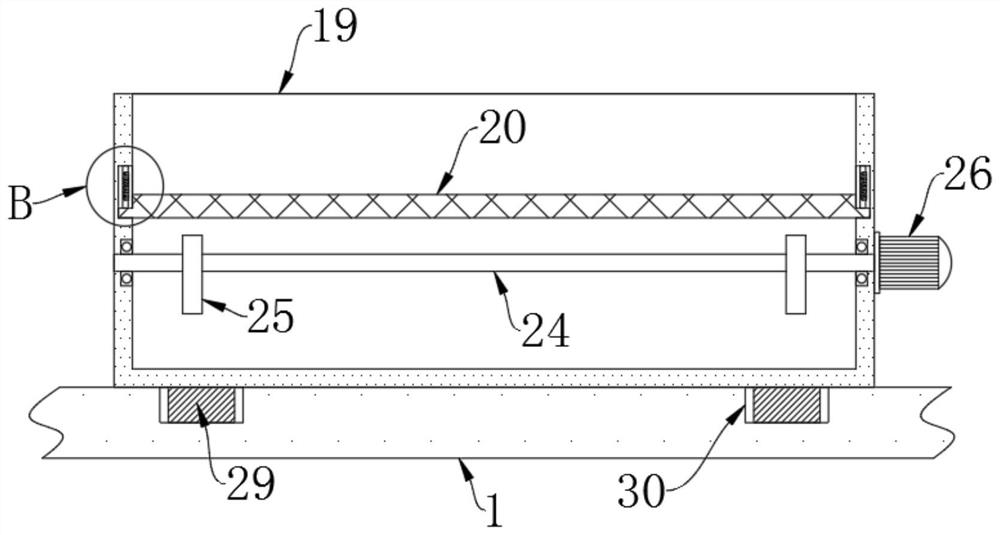

[0027] Such as Figure 1-5 As shown, a system for collecting and utilizing rebound materials of shotcrete in highway tunnels includes a base 1, on which a crushing box 2 is fixedly connected, and two crushing rollers 3 are rotatably connected in the crushing box 2, and are rotatably connected in the crushing box 2. There is a cleaning roller 4 matched with the crushing roller 3, and each crushing roller 3 and cleaning roller 4 are coaxially fixed with a worm gear 5, and a worm 6 is rotatably connected to the crushing box 2, and the worm 6 meshes with each worm gear 5, and the worm 6 There are four sections of thread on the top, and the direction of adjacent threads is opposite. The thread design on the worm 6 can make the adjacent crushing roller 3, and the adjacent cleaning roller 4 and crushing roller 3 move in opposite directions, which can effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com