Rotary disc with disturbance structure for metal centrifugal atomization powder making

A technology of centrifugal atomization and turntable, which is applied in the direction of improving process efficiency and energy efficiency, and can solve problems such as large centrifugal force and vibration, high requirements for turntable strength, and no refractory material inclusions, energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

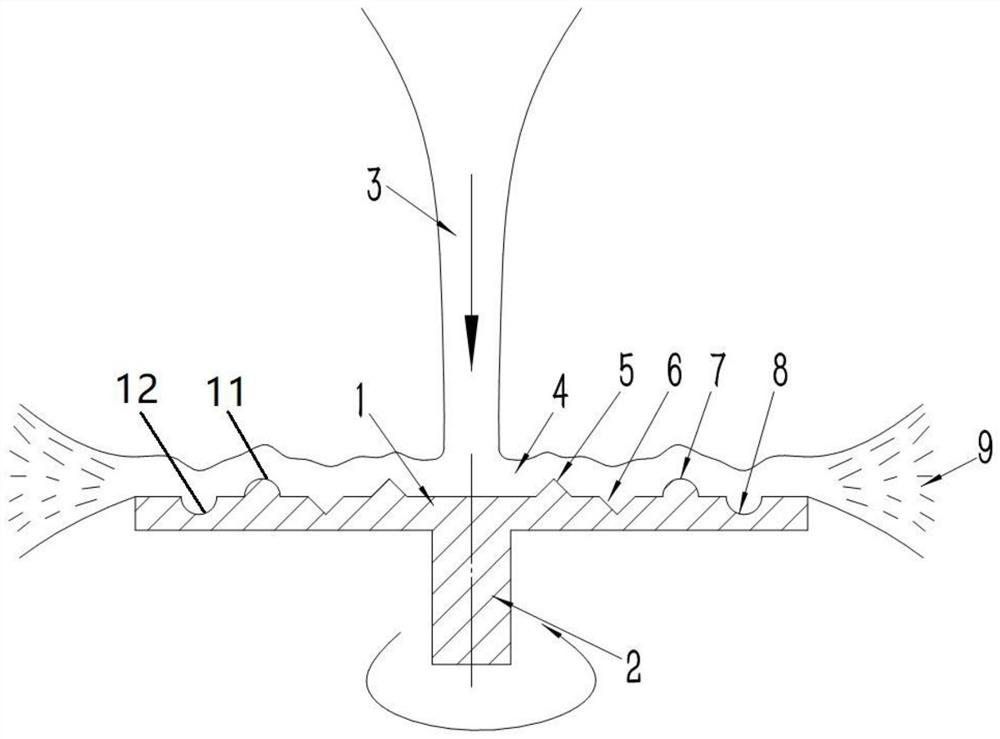

[0015] Such as figure 1 As shown, in one embodiment of the present invention, a turntable with a disturbance structure for metal centrifugal atomization pulverization is disclosed, which includes a cylindrical disc body with a diameter of 30 to 200, The thickness is 0.5-10 mm; the disc body is made of metal or non-metal material, that is, any material that can withstand the temperature of the metal liquid flow is acceptable. A disk shaft is fixed at the center of the lower surface of the disk body, and the disk shaft is used for connecting other components.

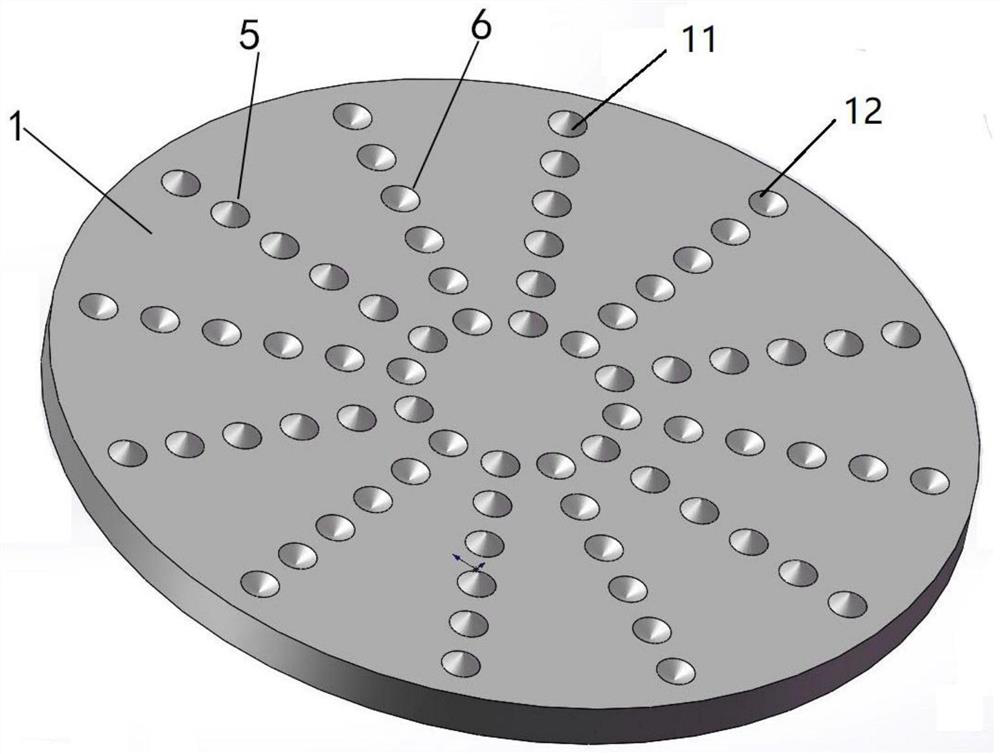

[0016] Protrusions and grooves are arranged on the upper surface of the disk body. The protrusion takes the center of the disc body as the base point, and is symmetrically arranged on the upper surface of the disc center, and adopts a multi-circle annular d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com