An automatic tension adjustment system and working method of a building membrane structure

A technology of automatic adjustment and working method, which is applied in the direction of building construction, construction, and building material processing, etc., can solve problems such as limited maintenance space, difficult adjustment and maintenance, and change of body size, so as to achieve easy operation and prevent insufficient membrane surface effect , the effect of avoiding maintenance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

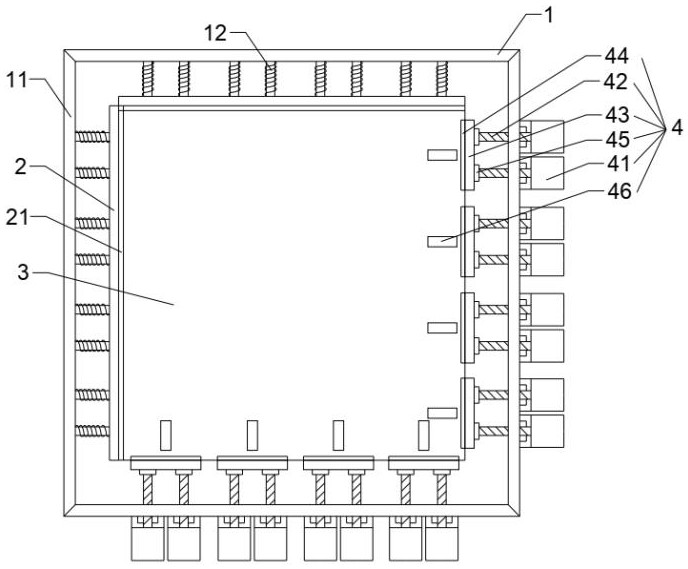

[0046] Such as figure 1 As shown, a building membrane structure tension automatic adjustment system includes a rectangular frame 1, which is formed by four square steel pipes 11 fixed end to end in turn, a membrane structure 3, which is arranged on the rectangular frame 1, including an electric adjustment screw 4, It includes:

[0047] The second rigid link 43 is distributed on a pair of adjacent edge portions of the membrane structure 3 at intervals;

[0048] A screw 42, one end of which is rotatably connected to the second rigid link 43, and the screw 42 moves along its axial direction to push and pull the second rigid link 43;

[0049] The motor 41 is connected to the other end of the screw 42 and drives the screw 42 to rotate forward and reverse, and the motor 41 is fixed on the rectangular frame 1 .

[0050] With such a structure, one side of the membrane structure 3 and its borders are fixed to the rectangular frame 1 by several electric adjustment screws 4, and severa...

Embodiment 2

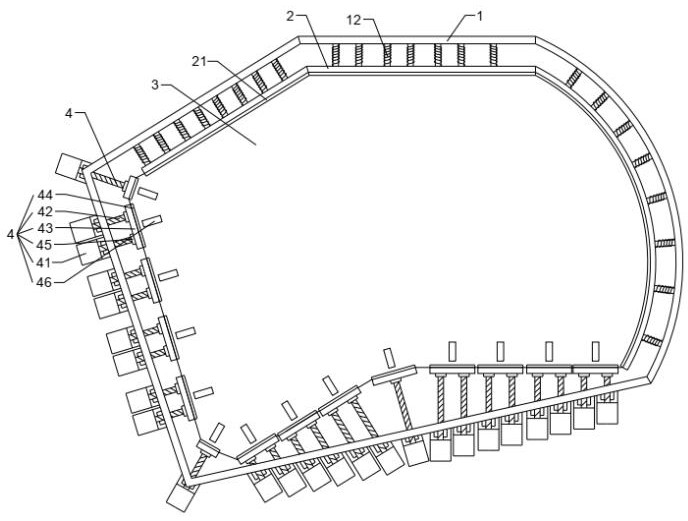

[0078] The difference between this embodiment and Embodiment 1 is that the membrane structure 3 in this embodiment is a special-shaped structure, wherein the screw 42 pushes and pulls the second rigid connecting rod 43 along its axial direction so as to tighten or loosen the membrane surface. The axial direction depends on the length direction of the first clamp 21 facing it. The stretching direction of the strain gauge 46 is the same as the axial direction of the screw 42 .

[0079] Such as figure 2 As shown, the membrane structure 3 of this embodiment is an irregular shaped structure, and there are respectively straight-sided and arc-shaped first clamps 21, wherein:

[0080] When the first clamp 21 is straight, the axial direction of the screw 42 is perpendicular to the length direction of the first clamp 21 .

[0081] When the membrane structure 3 is an arc-shaped structure, corresponding to the membrane structure 3, the first clamp 21 is an arc-shaped edge; The arc bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com