Anti-collapse device for expressway tunnel engineering

A technology for tunnel engineering and highways, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as bulky volume, affecting the speed of tunnel construction, and low structural strength of cast-in-place concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

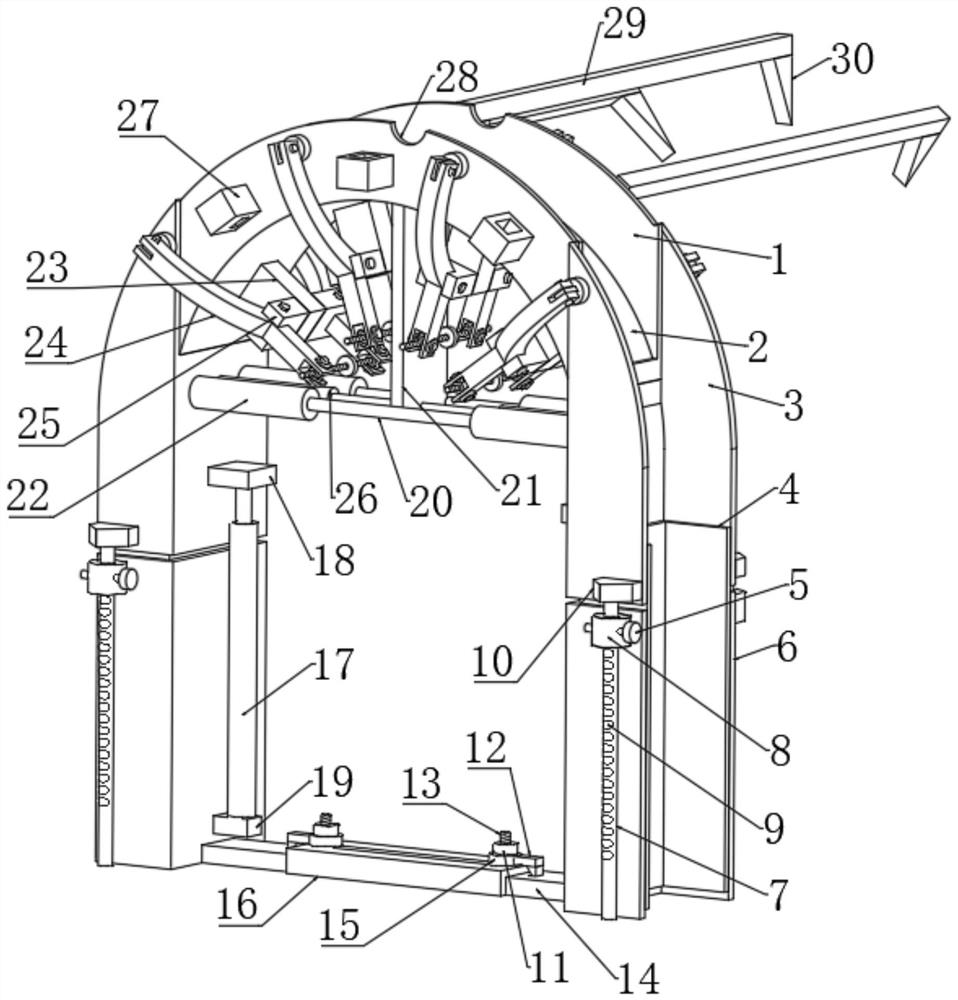

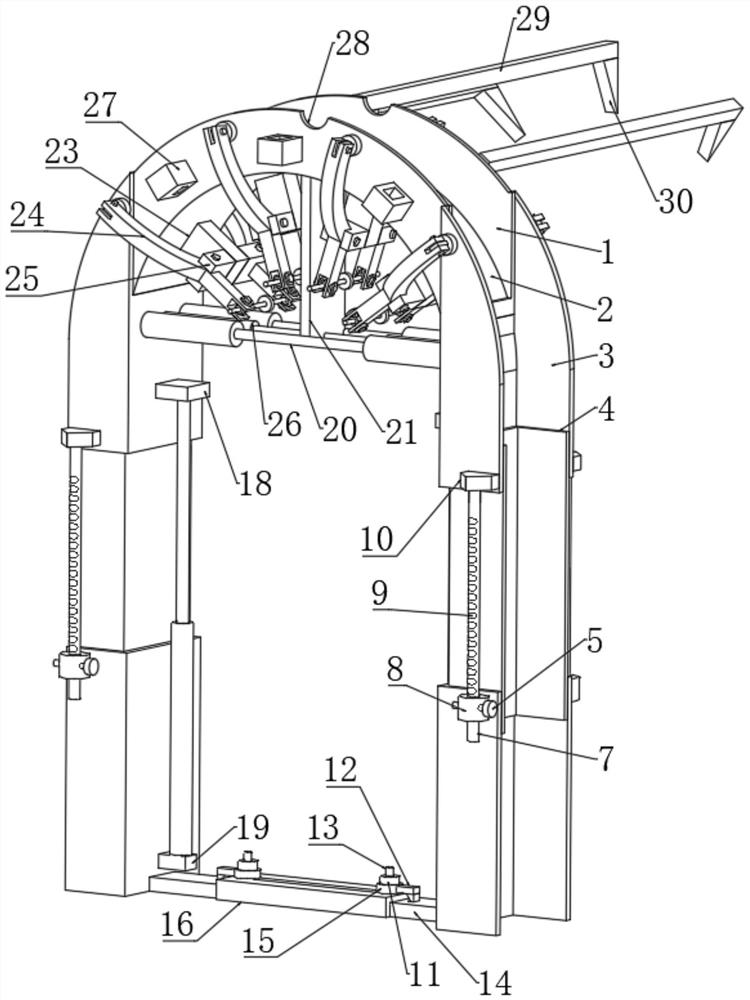

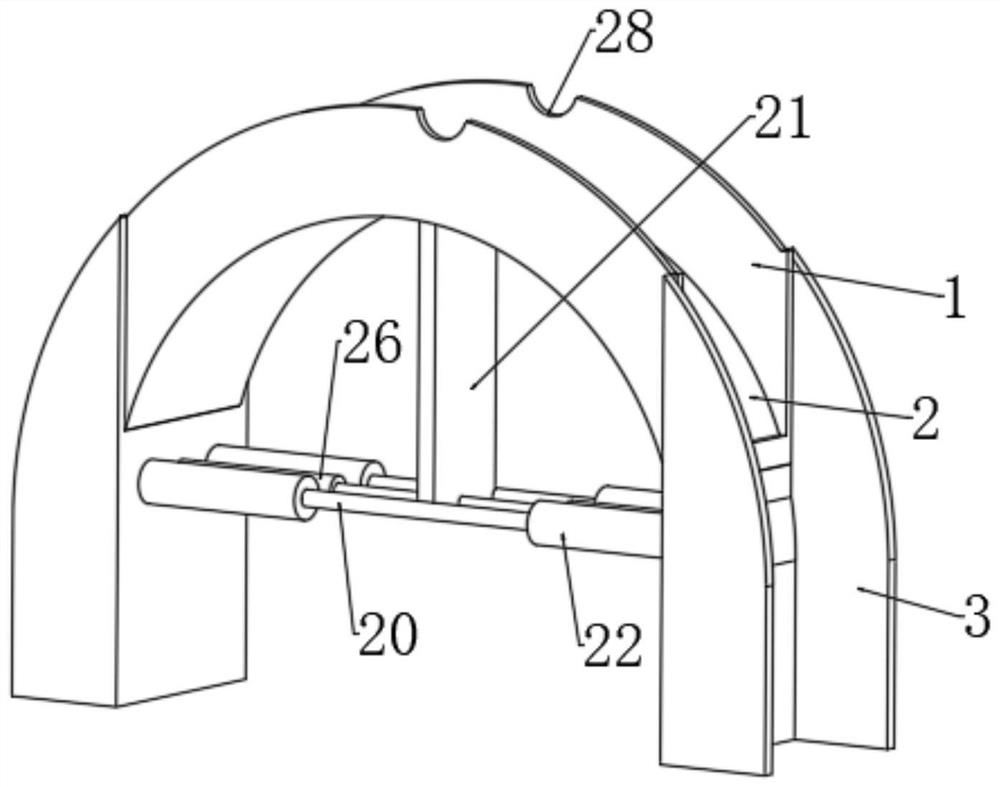

[0028] refer to Figure 1 to Figure 7, an anti-collapse device for expressway tunnel engineering, comprising a web 2 and a support rod 29, the upper end of the web 2 is symmetrically fixedly connected with two wing plates 1, and the upper edges of the two wing plates 1 are provided with grouting gaps 28. The center of the lower end of the web 2 is fixedly connected with a support plate 21, and the lower end of the support plate 21 is fixedly connected with two cross bars 20. The lower end of the web 2 is provided with two first steel molds 3, two first steel molds The opposite side of the mold 3 is fixedly connected with two horizontal tubes 22, and the two horizontal tubes 22 are respectively slidingly socketed with the rod walls of the two horizontal bars 20, and the opposite sides of the support plate 21 are fixedly connected with the first hydraulic cylinder 26 , the opposite ends of the two first hydraulic cylinders 26 are respectively fixedly connected to the side walls ...

Embodiment 2

[0030] Embodiment 2: the difference based on Embodiment 1 is;

[0031] refer to figure 2 and Figure 6 , the connection mechanism includes a fixed block 18, one end of the fixed block 18 is fixedly connected with the side wall of the first steel mold 3, the lower end of the fixed block 18 is fixedly connected with the second hydraulic cylinder 17, and the lower end of the second hydraulic cylinder 17 is fixedly connected with a support block 19, one end of the support block 19 is fixedly connected to one side of the third steel mold 6, the opposite sides of the first steel mold 3 are fixedly connected with installation blocks 10, and the lower ends of the two installation blocks 10 are fixedly connected with positioning rods 7. A positioning sleeve 8 is slidingly sleeved on the rod wall of the positioning rod 7, and one side of the positioning sleeve 8 is fixedly connected with one side of the third steel mold 6. One side of the positioning sleeve 8 is provided with a positi...

Embodiment 3

[0034] Embodiment 3: the difference based on embodiment 1 is;

[0035] refer to Figure 5 , the positioning mechanism includes two positioning curved rods 24, and one end of the two positioning curved rods 24 is provided with a mounting groove, and in the two mounting grooves, an internal threaded pipe 31 is connected through a rotating shaft, and one side of the connecting block 23 is provided with a two-way Screw rod 32, the rod wall row of two-way screw rod 32 is threadedly connected with internally threaded pipe 31 in two mounting grooves respectively, and the center of the rod wall of two-way screw rod 32 is fixedly connected with hand wheel 33, and the rod wall of positioning bending rod 24 A U-shaped block 25 is rotatably connected by a pin, and one side of the U-shaped block 25 is fixedly connected with one side of the connecting block 23. The end of the positioning curved rod 24 away from the installation groove is provided with an assembly groove, and the pin shaft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com