Method for measuring volume of rock-fill dam test pit through handheld three-dimensional laser scanning

A three-dimensional laser and hand-held technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large influence of human factors, acquisition of wrong data, and reduction of volume calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

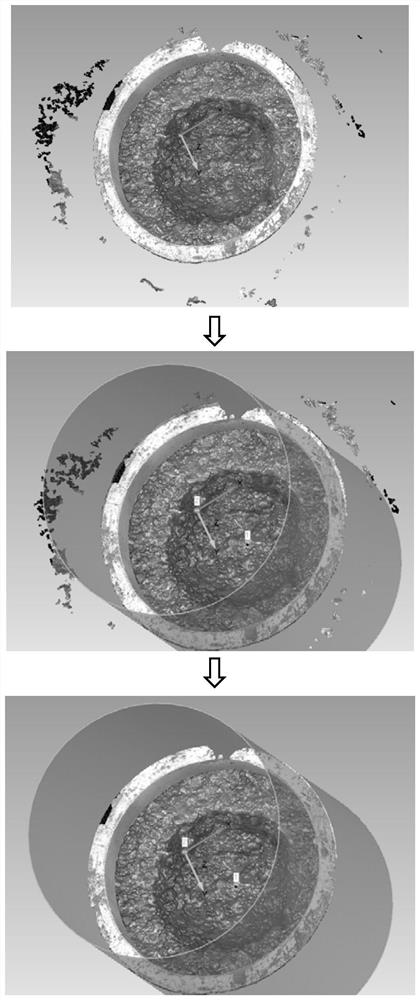

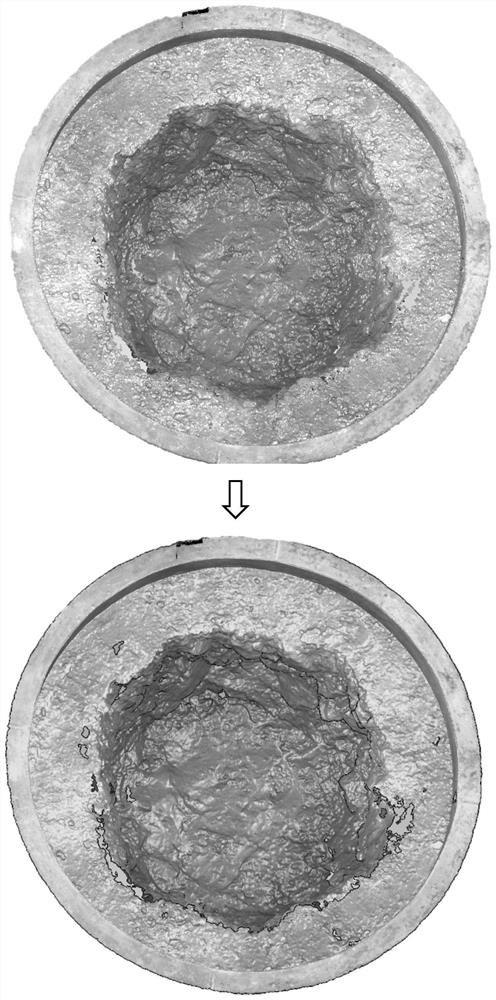

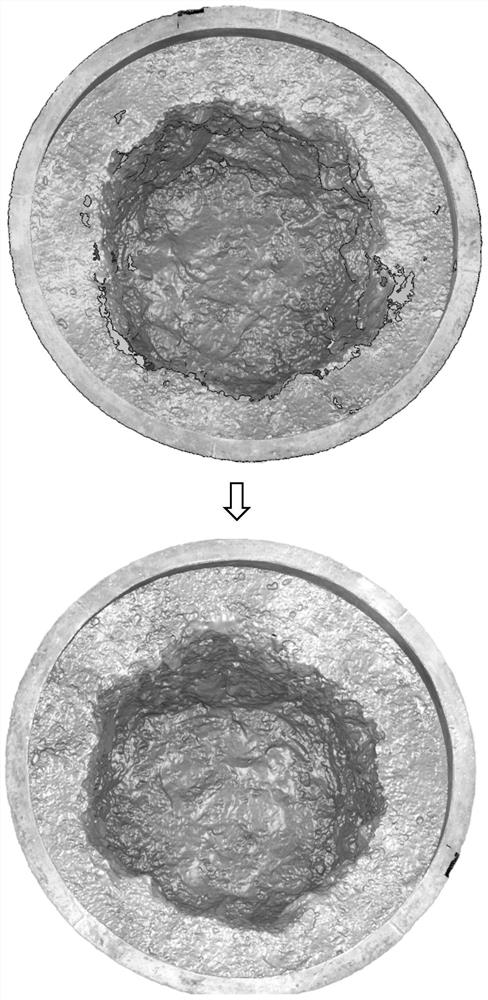

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The invention proposes a method for measuring the volume of a test pit based on a hand-held three-dimensional laser scanner. Its automatic positioning function can automatically register the scanning object during the scanning process, and the three-dimensional data on the surface of the test pit can be obtained without laying out marking points, which is extremely Greatly improved the work efficiency of measurement. The hand-held 3D laser scanner extends into the test pit for scanning, which can effectively deal with the serious problems of the unevenness of the test pit wall in the transitional material and rockfill yard, obtain accurate point cloud data, and improve the quality of point cloud data. The method of calculating the volume of the test pit by using the method of calculating the volume to the fitting plane after one scan an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com