Recycled aggregate evaluation and reinforcement method based on alkali aggregate reaction

A technology of recycled aggregates and alkali aggregates, which is applied in the analysis of materials, material inspection products, suspensions and porous materials, and can solve the problems of lack of evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

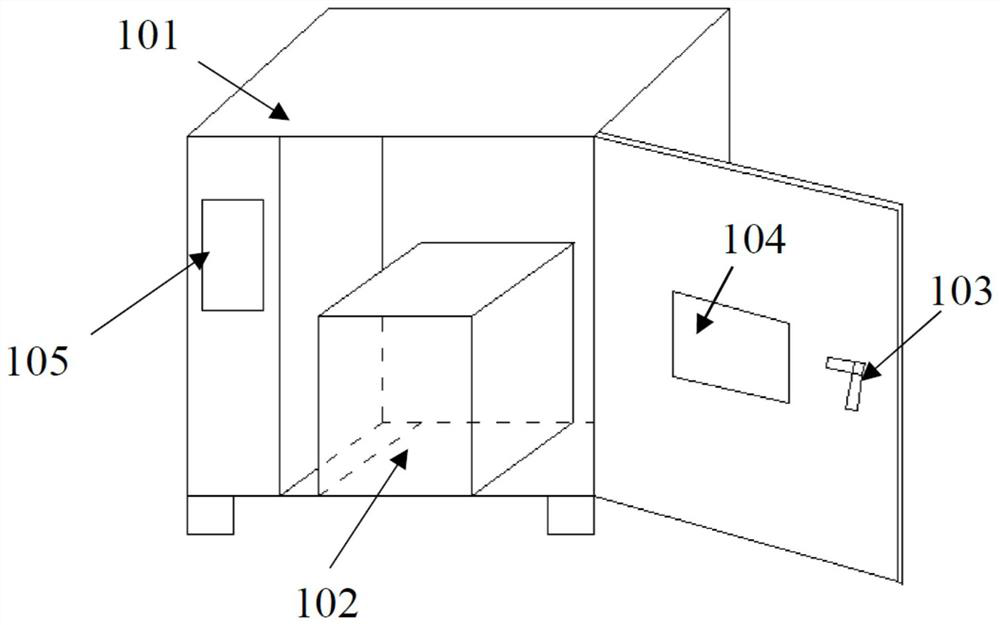

[0058] This example provides a device for strengthening recycled aggregates in the laboratory using alkali-aggregate reaction. Its structure is as follows figure 1 shown.

[0059] The device is a recycled aggregate strengthening experiment box 101. The recycled aggregate strengthening experiment box 101 is provided with an alkali aggregate reaction container 102, a temperature regulation controller 105 is provided on one side of the box body, and a handle 103, glass window 104.

[0060] When carrying out intensive experiments, the following steps can be followed:

[0061] Put the recycled aggregate to be strengthened into the alkali aggregate reaction container 102 in the recycled aggregate strengthening test box 101, pour NaOH solution, and close the test box.

[0062] Adjust the temperature regulation controller 105 on the control dial to control the reaction temperature required by the temperature to react.

[0063] After the experiment is completed, the soaked recycled ...

Embodiment 2

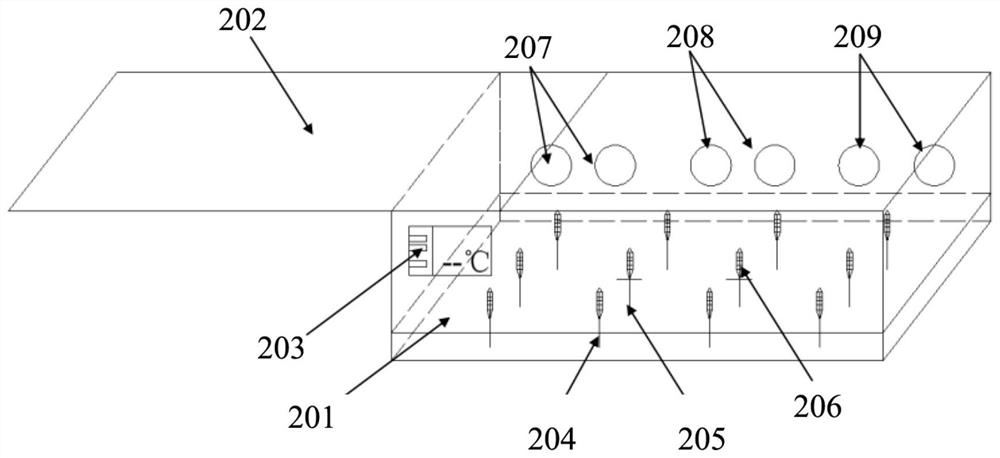

[0065] This embodiment provides a device for strengthening industrial recycled aggregate, the structure of which is as follows figure 2 shown.

[0066] The industrial recycled aggregate strengthening device includes a reaction tank 201, a reaction tank top cover 202, and a control panel 203, wherein:

[0067] The reaction tank top cover 202 is arranged on the top of the reaction tank 201 for closing the reaction tank 201;

[0068] Both sides of the top of the reaction tank 201 are provided with pulleys for controlling the opening and closing of the top cover 202 of the reaction tank;

[0069] The bottom of the reaction tank 201 is provided with a heating pipe 204 (for adjusting the temperature in the reaction tank), a temperature sensor 205 (displaying the temperature in the current reaction tank at the control panel), and an alkali solution concentration sensor 206 (displaying the temperature in the current reaction tank at the control panel). Alkaline solution concentrati...

Embodiment 3

[0077] This embodiment provides a method for evaluating and strengthening recycled aggregate based on alkali-aggregate reaction, which specifically includes the following steps:

[0078] The porosity of the recycled aggregate was determined to be 12.28% by mercury porosimetry;

[0079] The strength fc of the mortar to be prepared is 20MPa, and the porosity threshold is 10.28% according to the following relational formula:

[0080]

[0081] Wherein, the value of C is 75, the value of K is 0.3, and the value of Pcr is 0.25;

[0082] Since the porosity of the recycled aggregate is higher than the porosity threshold, it is judged that the recycled aggregate needs to be strengthened.

[0083] The hardening is carried out in the following steps:

[0084] Due to the large difference in porosity, a higher alkali solution concentration is selected, supplemented by a relatively higher soaking temperature;

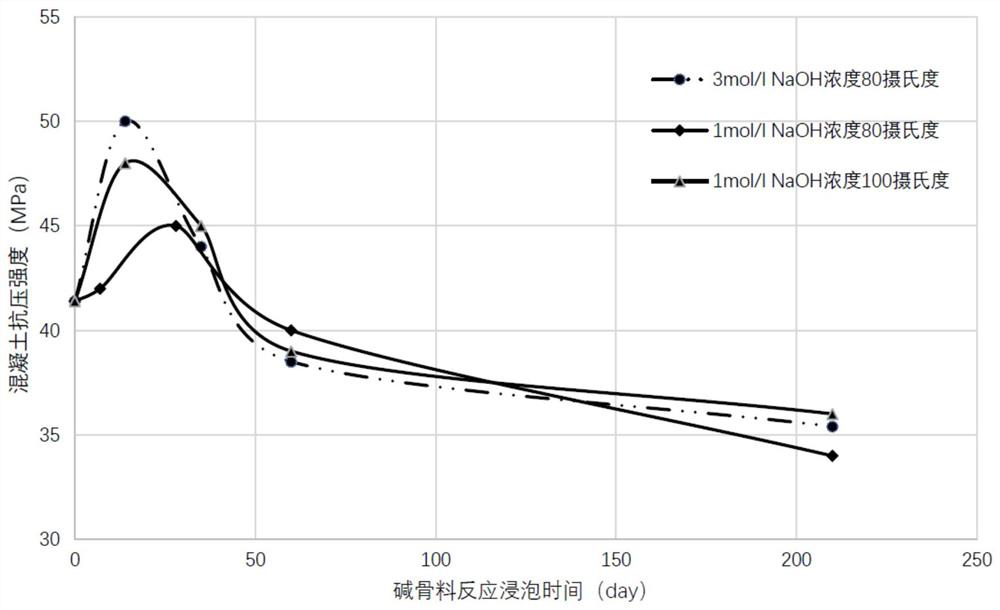

[0085] Soak the recycled aggregate in sodium hydroxide solutions with diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com