Infrared band-pass optical filter and sensor system

A band-pass filter and filter technology, applied in the field of optical filters, can solve the problem of reducing the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

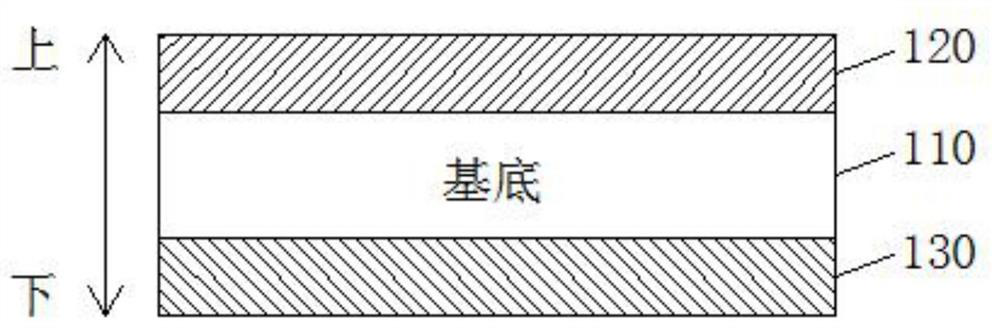

[0040] like figure 1 As shown, the present invention provides an infrared band-pass filter, which includes: a base 110 that isolates visible light from passing through infrared light, and a first structure 120 disposed on the upper surface of the base and a second structure 130 disposed on the lower surface of the substrate. The first structure includes multiple high-refractive-index layers and multiple low-refractive-index layers, and the high-refractive-index layers and the low-refractive-index layers are alternately stacked. The second structure includes multiple high-refractive index layers, multiple medium-refractive-index layers, and multiple low-refractive-index layers, and the high-refractive-index layers, the medium-refractive-index layers, and the low-refractive-index layers are alternately stacked .

[0041] In an embodiment of the present invention, the substrate is infrared glass or transparent glass coated with an absorbing material; the thickness of the substr...

Embodiment 2

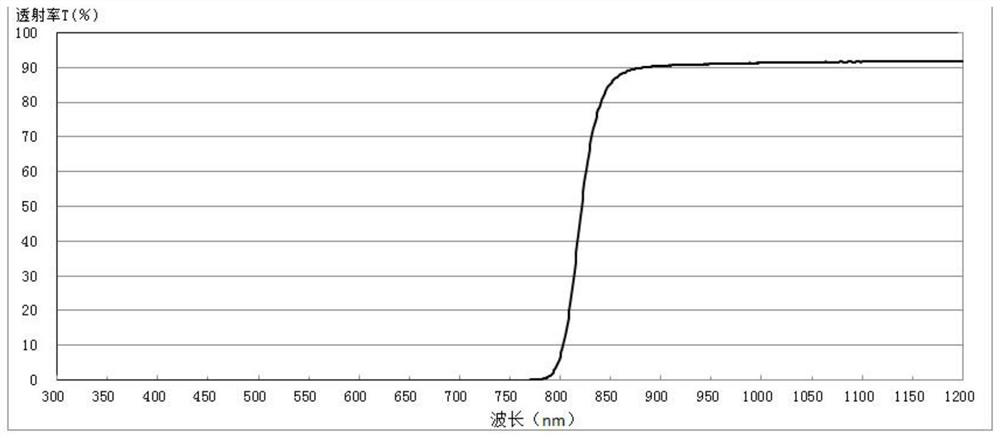

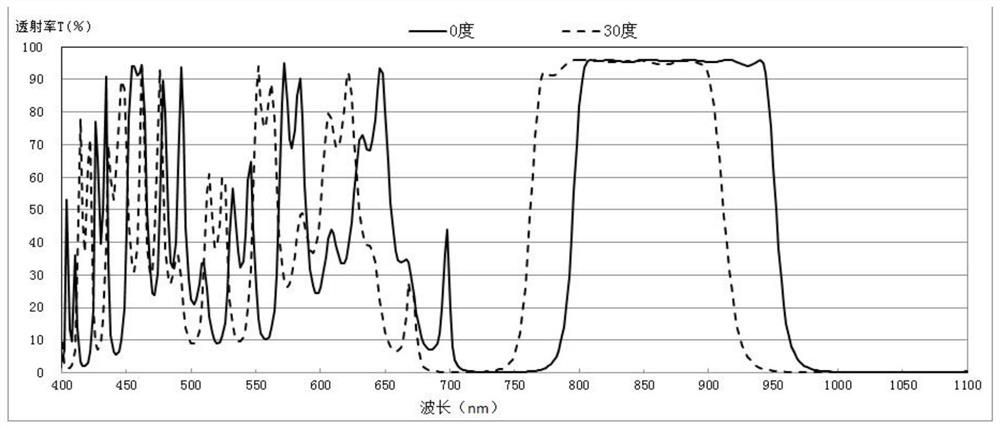

[0046] Embodiment 2 is a further embodiment based on Embodiment 1. In the embodiment of the present invention, the wavelength of the passband of the infrared bandpass filter includes 850 nm. Each high refractive index layer is formed by deposition of trititanium pentoxide. Each medium index layer is formed by deposition of tantalum pentoxide. Each low refractive index layer is formed by silicon dioxide deposition. When preparing the first structure 120 and the second structure 130 , electron beam evaporation and ion-assisted deposition are both used, and a correction plate (mask) combined with an extremum method is used to control the thickness of the film layer. It should be noted that the vacuum degree and deposition rate during deposition should be controlled during preparation, and the process conditions should be optimized to obtain the best evaporated film. In the embodiment of the present invention, the substrate 110 is made of infrared glass that isolates visible li...

Embodiment 3

[0057] The substrate in the embodiment of the present invention is the same as the substrate in embodiment 2. Each high-refractive index layer is formed by depositing titanium trioxide, each medium-refractive index layer is formed by depositing tantalum pentoxide, and each low-refractive index layer is formed by depositing silicon dioxide.

[0058] In the embodiment of the present invention, the total number of layers of the anti-reflection structure layer is 4 layers, the number of each of the high refractive index layer and the low refractive index layer is 2 layers, and the total film thickness is 370.73 nm. Furthermore, the thickness of the high refractive index layer forming the anti-reflection structure layer is 5nm-320nm, and the thickness of the low-refraction index layer forming the anti-reflection structure layer is 5nm-280nm, the anti-reflection structure layer of this embodiment The material and thickness of each layer are shown in Table 3.

[0059] Table 3: Mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com