Resistive random access memory and manufacturing method thereof

A resistive random access memory technology, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems of large available space, unfavorable miniaturization of memory devices, complex circuit design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

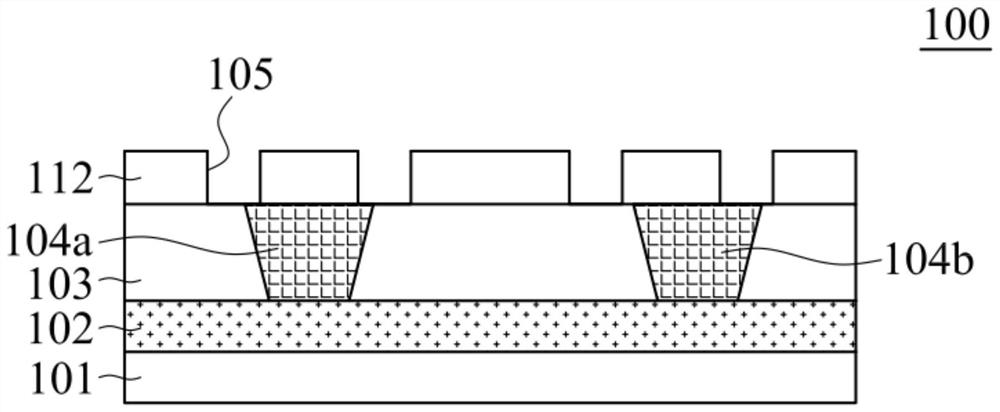

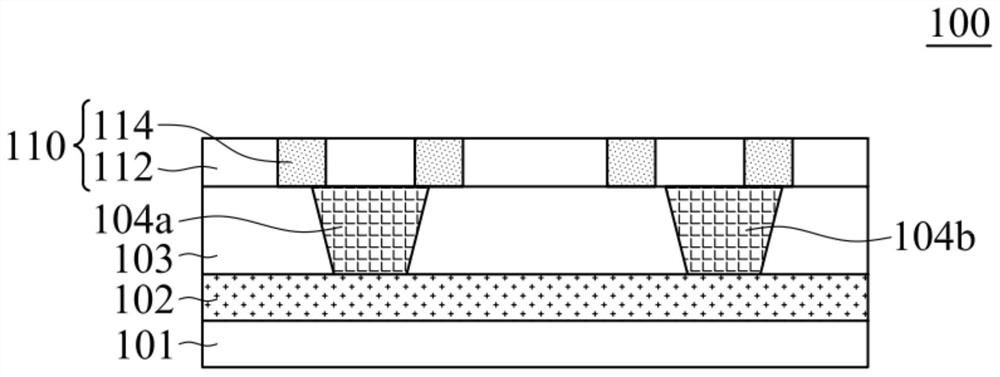

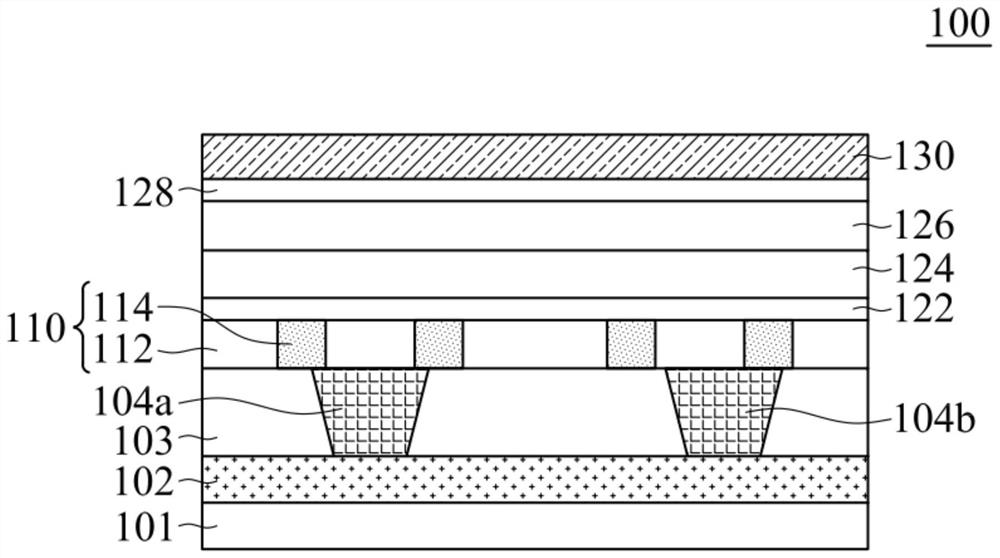

[0038] Figure 1A to Figure 1D It is a schematic cross-sectional view corresponding to each step of manufacturing the resistive random access memory 100 in some embodiments of the present invention. Please refer to Figure 1A , forming an interlayer dielectric layer 103 on the substrate 101 . The material of the substrate 101 may include a bulk semiconductor substrate (eg, a silicon substrate), a compound semiconductor substrate (eg, a Group IIIA-VA semiconductor substrate), a silicon on insulator (SOI) substrate, and the like. The substrate 101 can be a doped or undoped semiconductor substrate. In some embodiments, the substrate 101 is a silicon substrate. The interlayer dielectric layer 103 can be a suitable insulating material, such as nitride, oxide or ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com