Sectional five-phase permanent magnet motor rotor structure with unequal number of magnetic poles

A permanent magnet motor and rotor structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., can solve the problem of reducing motor stability, single permanent magnet is easy to damage, and motor output torque Pulsation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

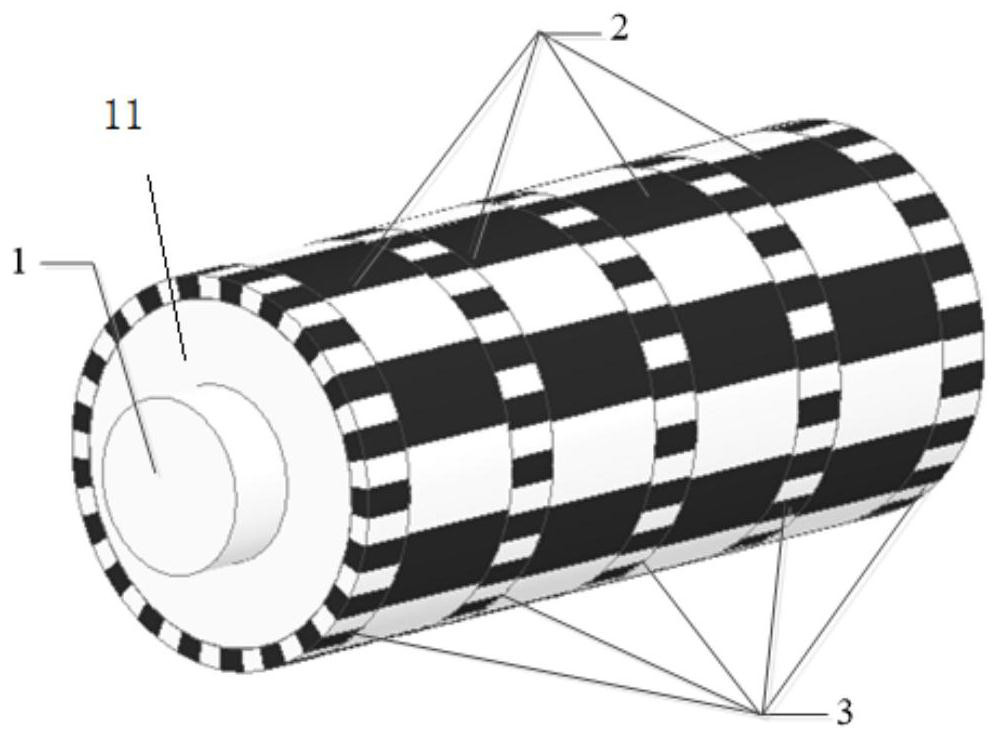

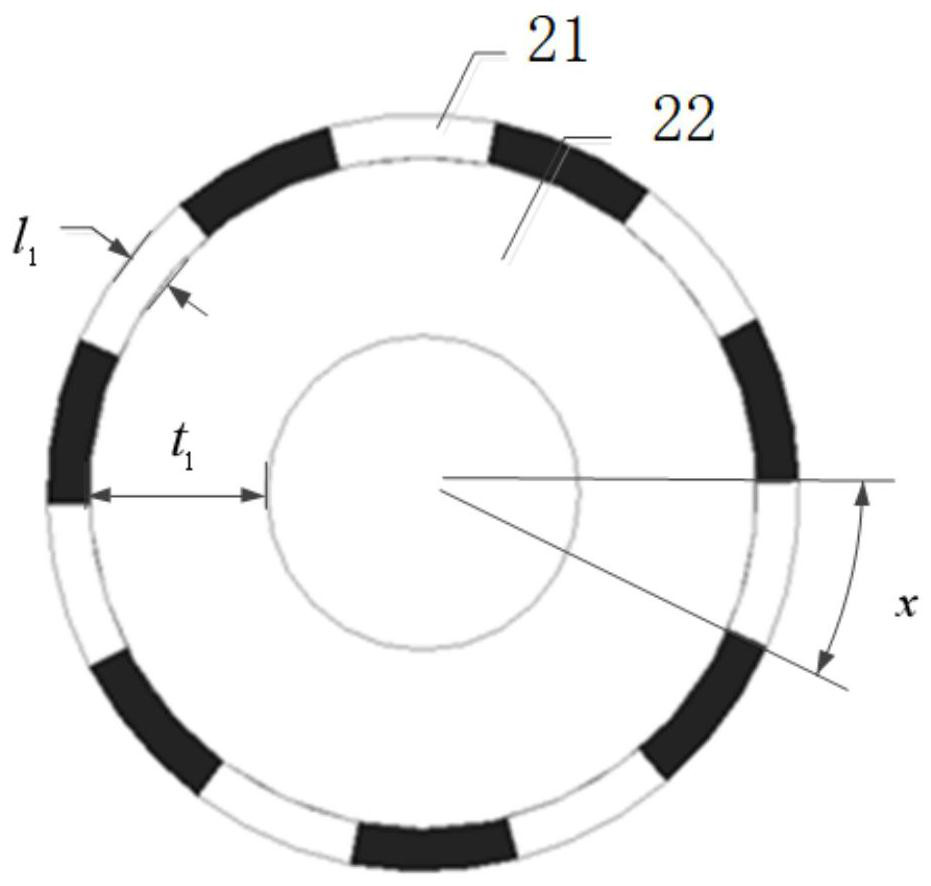

[0024] refer to figure 1 As shown, this embodiment is a five-phase permanent magnet motor rotor structure with unequal number of magnetic poles in segments, including a central shaft (1), a rotor unit (2) with N segment magnetic poles of 2p and N+1 segment magnetic poles of 6p The rotor unit (3) of the central rotating shaft (1) is provided with a number of laminated rotor cores (11), and the two groups of rotor units are alternately arranged along the axial outer circumference of the central rotating shaft (1). The same number of magnetic poles The axial lengths of the rotor units are equal.

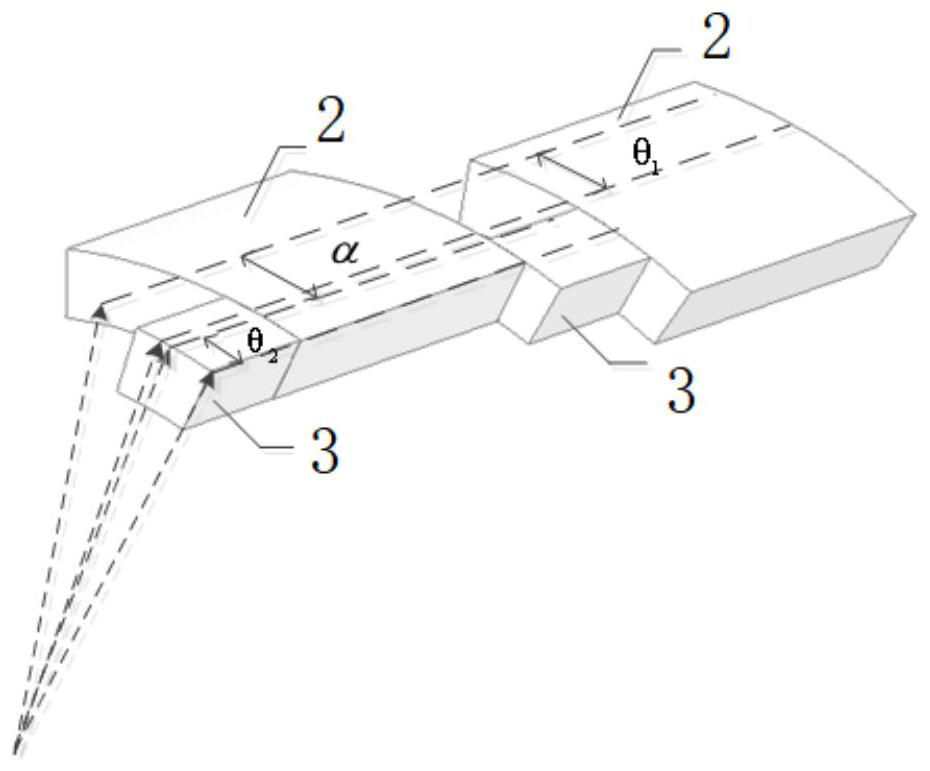

[0025] refer to figure 2 As shown, the rotor units of 2N+1 segments arranged axially along the central rotating shaft (1) are numbered 0, 1, 2, ..., 2N, where N is a positive integer.

[0026] The included angle between the magnetic pole centerlines of the 0th segment rotor unit and the 1st segment rotor unit is α, and the included angle between the magnetic pole centerlines of the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com