Pig back fat simulant and preparation method thereof

A technology of simulants and pig back fat, which is applied in the field of fat simulants and pig back fat simulants, can solve problems such as influence and cooking loss, and achieve the effects of simple process, easy availability of raw materials, and good processing and application feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

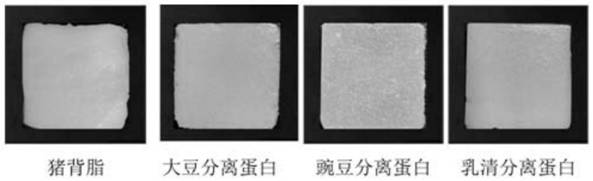

Image

Examples

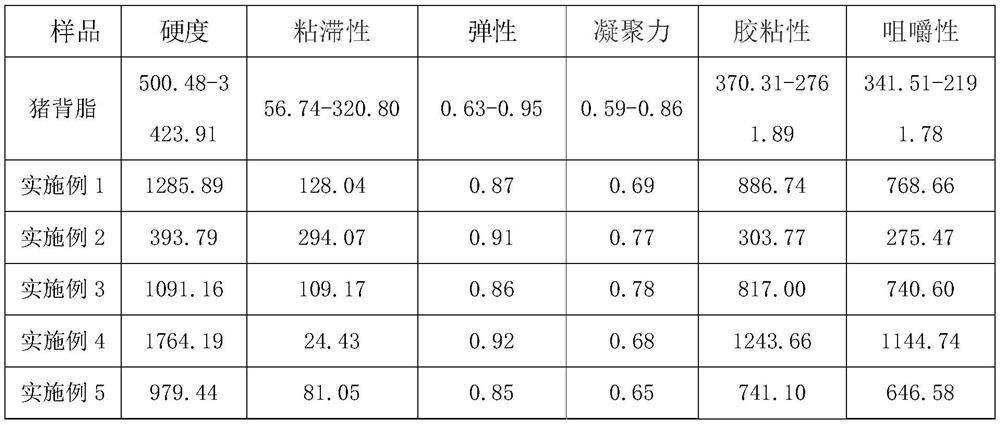

Embodiment 1

[0023] Soy protein isolate / whey protein isolate / pea protein isolate: 1.73%;

[0024] Palm oil: 9.6%;

[0025] Konjac gum: 3.4%;

[0026] Carrageenan: 0.6%;

[0027] Sodium carbonate: 0.36%;

[0028] Distilled water: balance.

[0029] The preparation method of the above-mentioned fat simulants, the steps are as follows:

[0030] (1) Preparation of the aqueous phase of the emulsion: Weigh the above three proteins into water, stir them magnetically for 2 hours, and then put them in a refrigerator at 4°C overnight to fully dissolve them to obtain a protein hydration solution;

[0031] (2) Shear emulsification treatment: heat the protein hydration solution in a water bath at 90°C for 10 minutes, add palm oil to it after cooling for a while, and shear at a high speed of 12000 rpm / min for 3 minutes to obtain an O / W emulsion;

[0032] (3) Add sodium carbonate to the emulsion, stir to dissolve, then continue to add konjac gum and carrageenan under the low-speed stirring of the mix...

Embodiment 2

[0036] Soy protein isolate: 1.73%;

[0037] Palm oil: 9.6%;

[0038] Konjac gum: 4.0%;

[0039] Sodium carbonate: 0.36%

[0040] Distilled water: balance;

[0041] The preparation method is the same as in Example 1, except that the raw materials do not contain carrageenan.

Embodiment 3

[0043] Soy protein isolate: 2.2%;

[0044] Palm oil: 13.5%;

[0045] Konjac gum: 5%;

[0046] Carrageenan: 0.4%;

[0047] Sodium carbonate: 0.45%;

[0048] Distilled water: balance.

[0049] The preparation method is the same as that of Example 1, the only difference being that the ratio of raw materials is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com