High-stability intelligent equipment for mechanical manufacturing

A technology for machinery manufacturing and intelligent equipment, applied in the field of intelligent equipment for high-stability machinery manufacturing, can solve problems such as poor stability, achieve clean processing stations, improve the scope of tightening adaptation, and achieve the effects of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

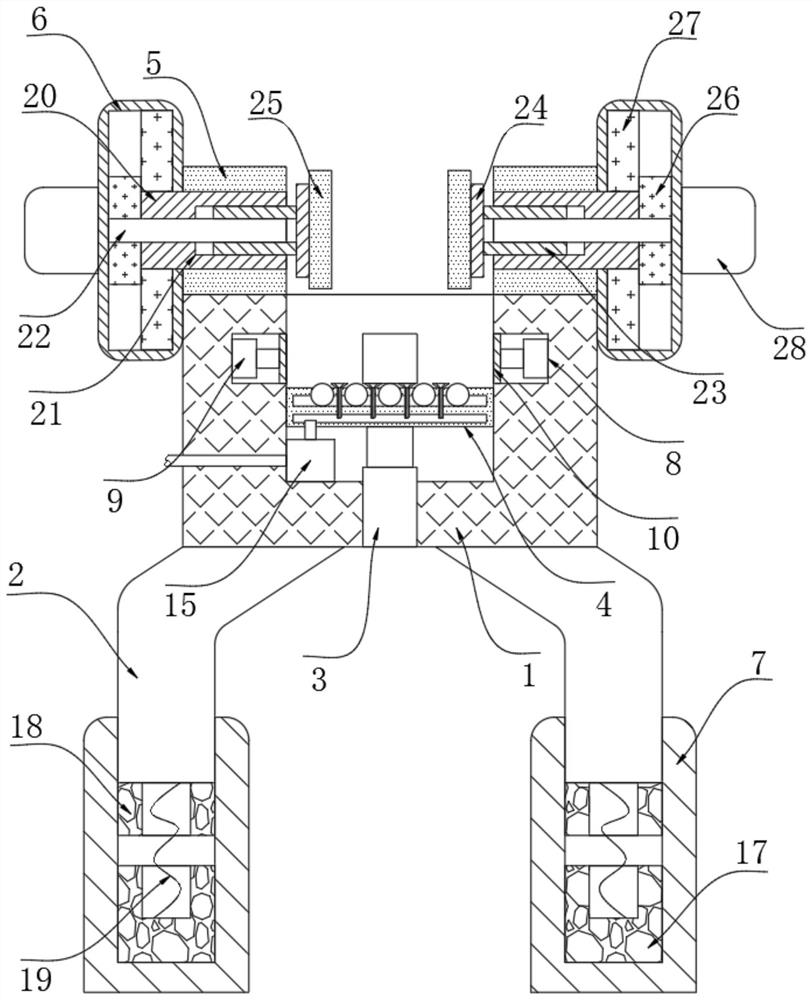

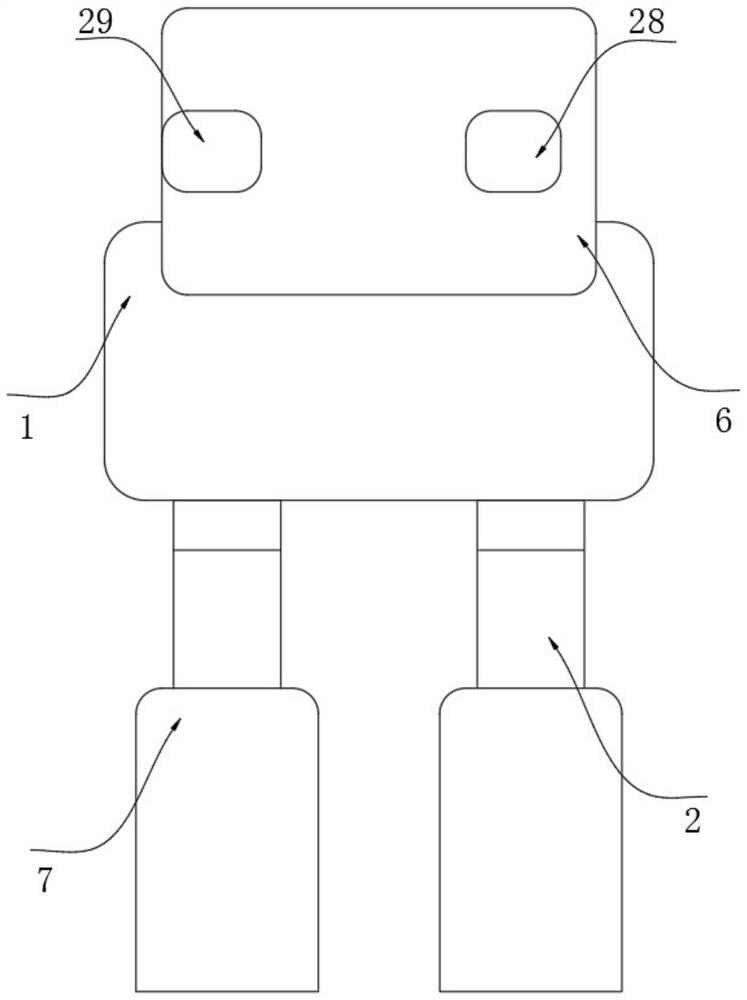

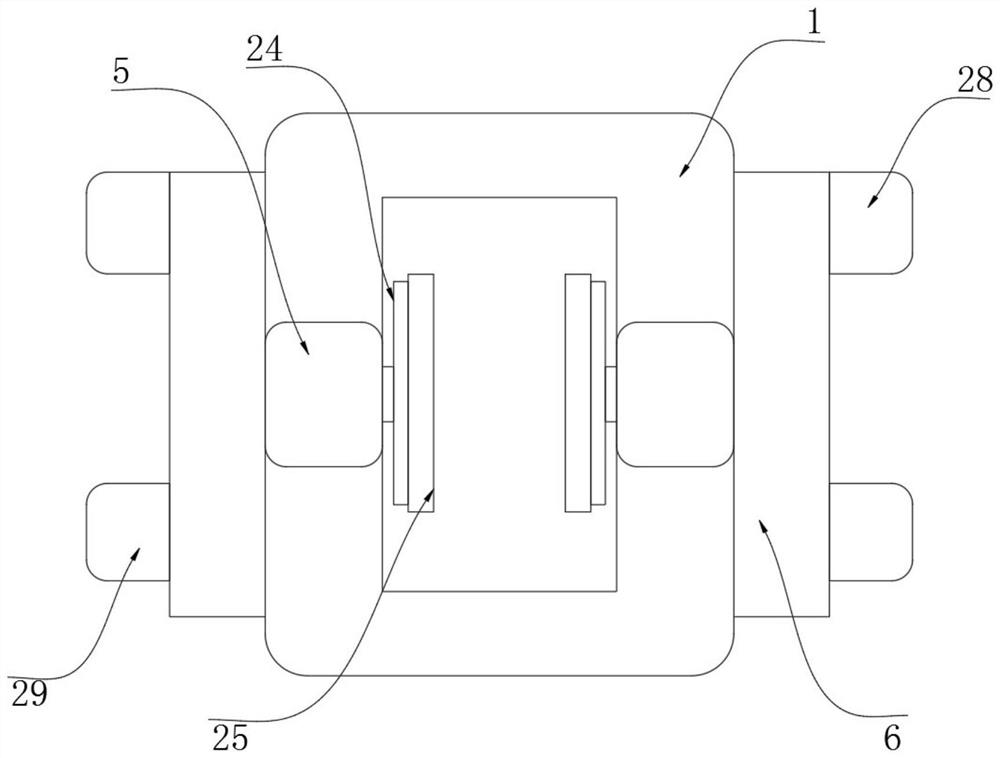

[0027] refer to Figure 1-5 , an intelligent equipment for high-stability machinery manufacturing, including a processing table 1, a plurality of brackets 2 are fixed on the bottom of the processing table 1, a stable shock absorbing mechanism is connected to the bottom of each bracket 2, and the inner bottom of the processing table 1 runs through A hydraulic cylinder 3 is fixed, and a positioning plate 4 is fixed on the upper end of the hydraulic cylinder 3. A positioning auxiliary mechanism is arranged on the positioning plate 4. Two symmetrically arranged clamping tables 5 are fixed on the upper end of the processing table 1. The two clamping tables 5 The side walls of each are fixed with a power box 6, the inside of the clamping table 5 is provided with a clamping mechanism, and the inside of the power box 6 is provided with a driving mechanism.

[0028] The positioning auxiliary mechanism includes an air pumping chamber 11 and a rolling chamber 12 opened inside the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com