Production equipment of stitch-bonded cleaning fabrics

A technology of production equipment and cleaning cloth, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of reducing the production and processing quality of silk cloth, failing to achieve adjustment, and affecting silk cloth processing, etc., to achieve High-quality transmission, the effect of satisfying tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below:

[0023] For details, see Figure 1 to Figure 4 :

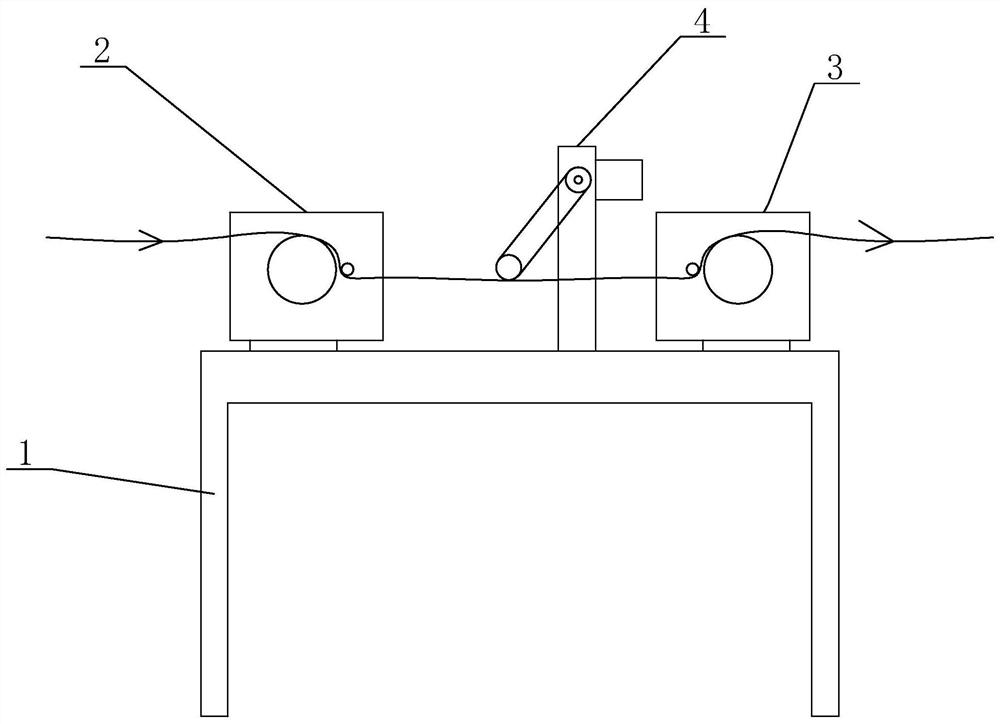

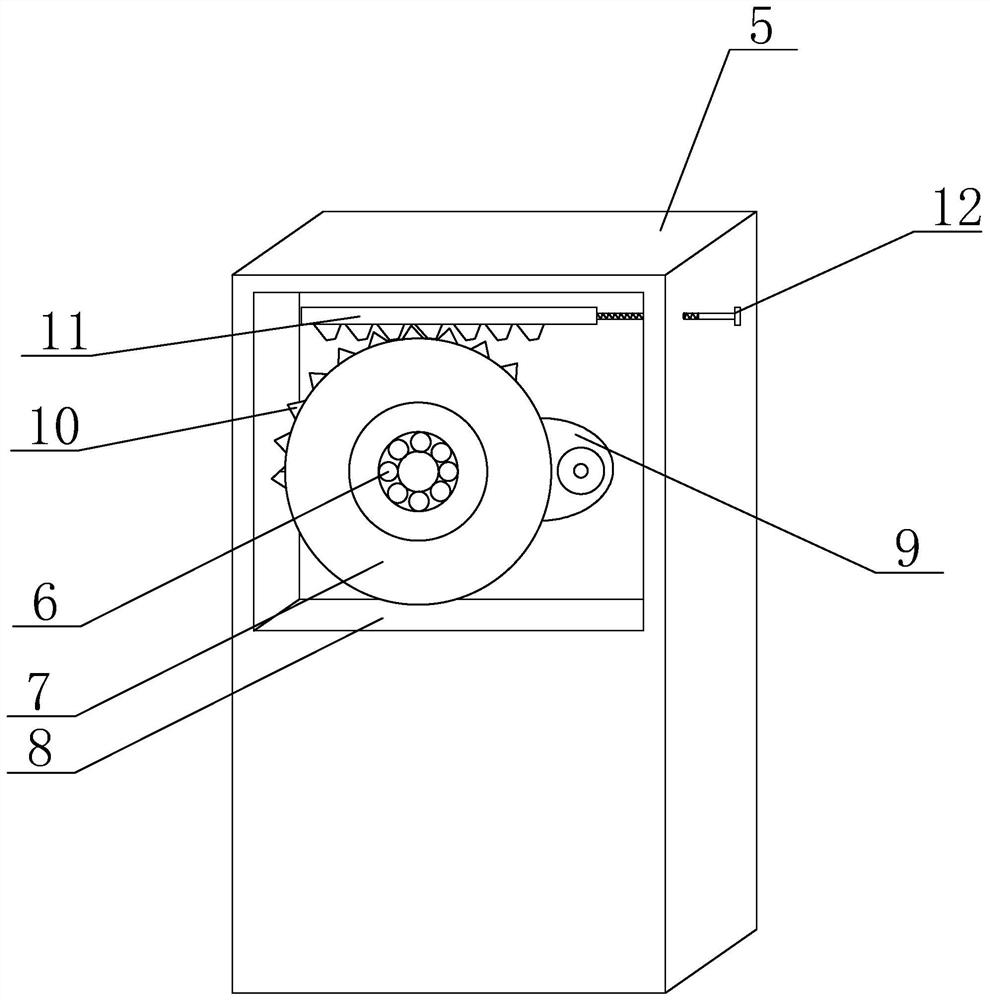

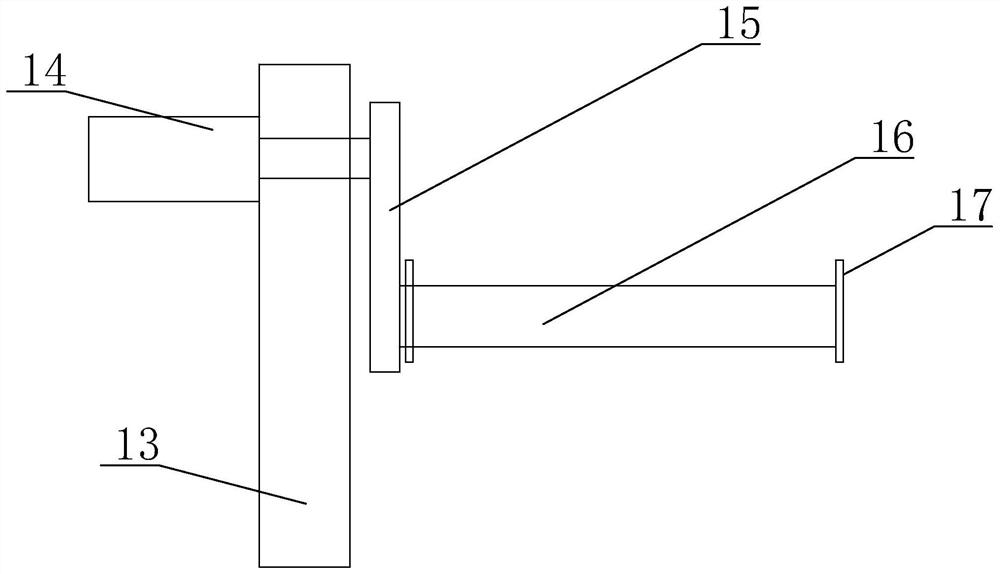

[0024] A kind of production equipment of stitching cleaning cloth, it comprises support table 1, on support table 1 along the conveying direction of cloth, the first cloth guiding device 2, cloth pressing device 4 and the second cloth guiding device 3 are arranged sequentially, described The cloth pressing device 4 can provide downward pressure for the cloth, and the first cloth guiding device 2 and the second cloth guiding device 3 both include a left mounting seat 5, a right mounting seat, a bearing 6, a wheel disc 7, a guide roller, a pressure roller and The drive mechanism, the left mounting base 5 and the right mounting base are arranged oppositely, and the inner sides of the left mounting base 5 and the right mounting base are provided with mounting grooves 8, and the two ends of the guide rollers are rotatable through the bearings 6 and the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com