Multifunctional integrated oil-mud-water separation device

A separation device, mud-water separation technology, applied in water/sludge/sewage treatment, centrifugal separation of water/sewage treatment, water pollutants, etc., can solve the problems of inconvenient sludge cleaning, large floor space, and high operating costs. Achieve the effects of easy maintenance, reduced floor space, and improved oil separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

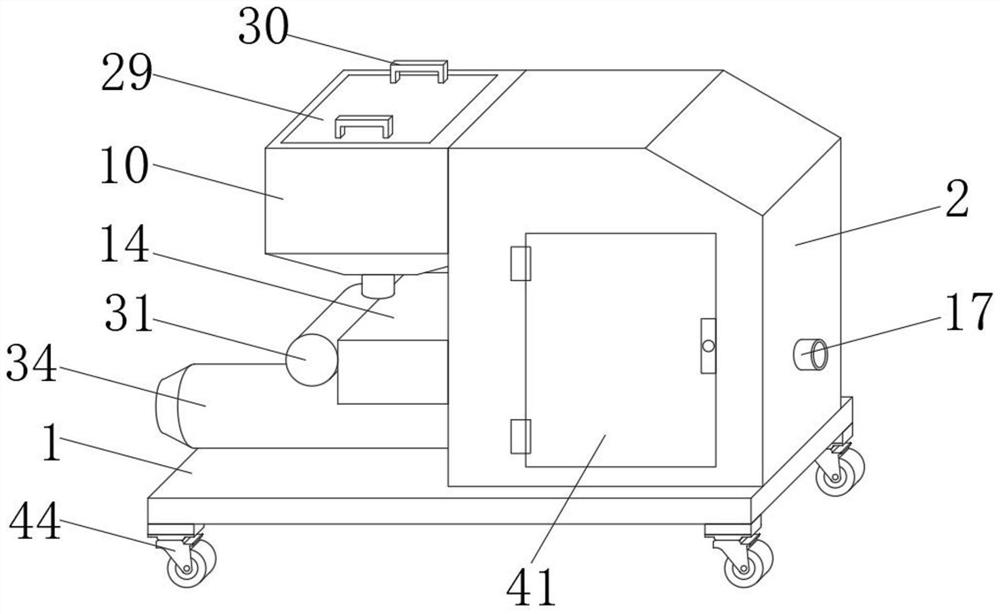

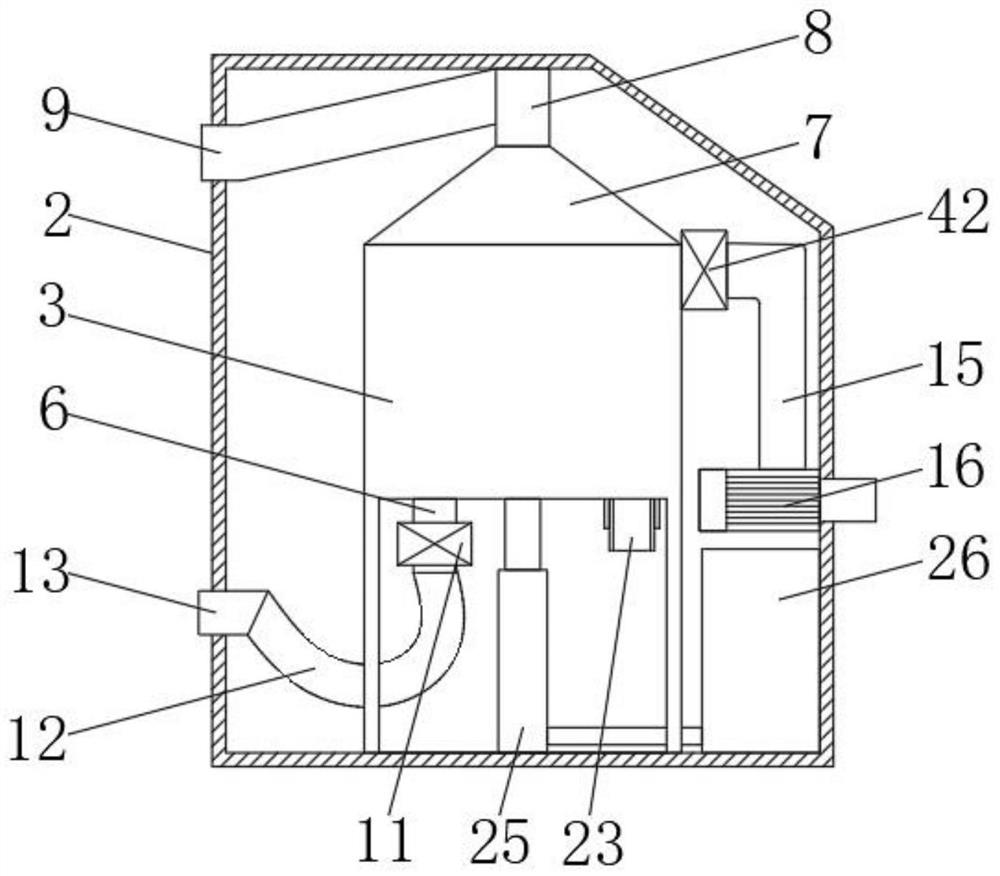

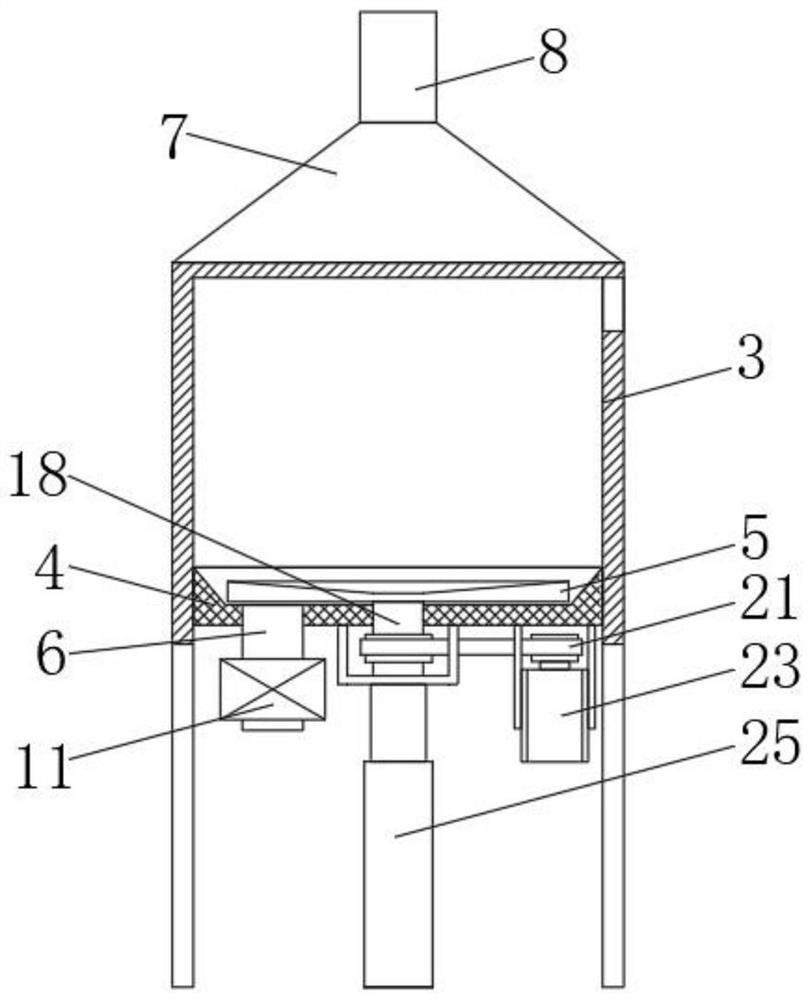

[0032] see Figure 1-3 , the present invention provides a technical solution: a multi-functional integrated oil sludge water separation device, including a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a device casing 2, the inside of the device casing 2 is fixedly connected with an oil separation tank 3, and the inside of the oil separation tank 3 slides The piston 4 is connected, the inner side of the piston 4 is rotated and connected to the centrifugal turntable 5, the bottom end of the inner side of the piston 4 is fixedly connected to the sewage pipe 6, the top of the oil separation tank 3 is fixedly connected to the conical cover 7, and the top of the conical cover 7 is fixedly connected to a sink. The oil pipe 8 and the outer side of the oil collection pipe 8 are fixedly connected with an oil discharge pipe 9, and the other end of the oil discharge pipe 9 is located inside the oil distribution tank 10. By setting the device casing 2, the inside ...

Embodiment 2

[0035] see Figure 1-8, the present invention provides a technical solution: a multi-functional integrated oil sludge water separation device, including a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a device casing 2, the inside of the device casing 2 is fixedly connected with an oil separation tank 3, and the inside of the oil separation tank 3 slides The piston 4 is connected, the inner side of the piston 4 is rotated and connected to the centrifugal turntable 5, the bottom end of the inner side of the piston 4 is fixedly connected to the sewage pipe 6, the top of the oil separation tank 3 is fixedly connected to the conical cover 7, and the top of the conical cover 7 is fixedly connected to a sink. The oil pipe 8 and the outer side of the oil collection pipe 8 are fixedly connected with an oil discharge pipe 9, and the other end of the oil discharge pipe 9 is located inside the oil distribution tank 10. By setting the device casing 2, the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com