Coordinated water-containing lead-free all-inorganic indium-based zero-dimensional perovskite nanocrystal and preparation method thereof

A technology of nanocrystals and production methods, applied in chemical instruments and methods, semiconductor devices, luminescent materials, etc., to achieve the effect of excellent red fluorescence, good optoelectronic application prospects, and strong yellow fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

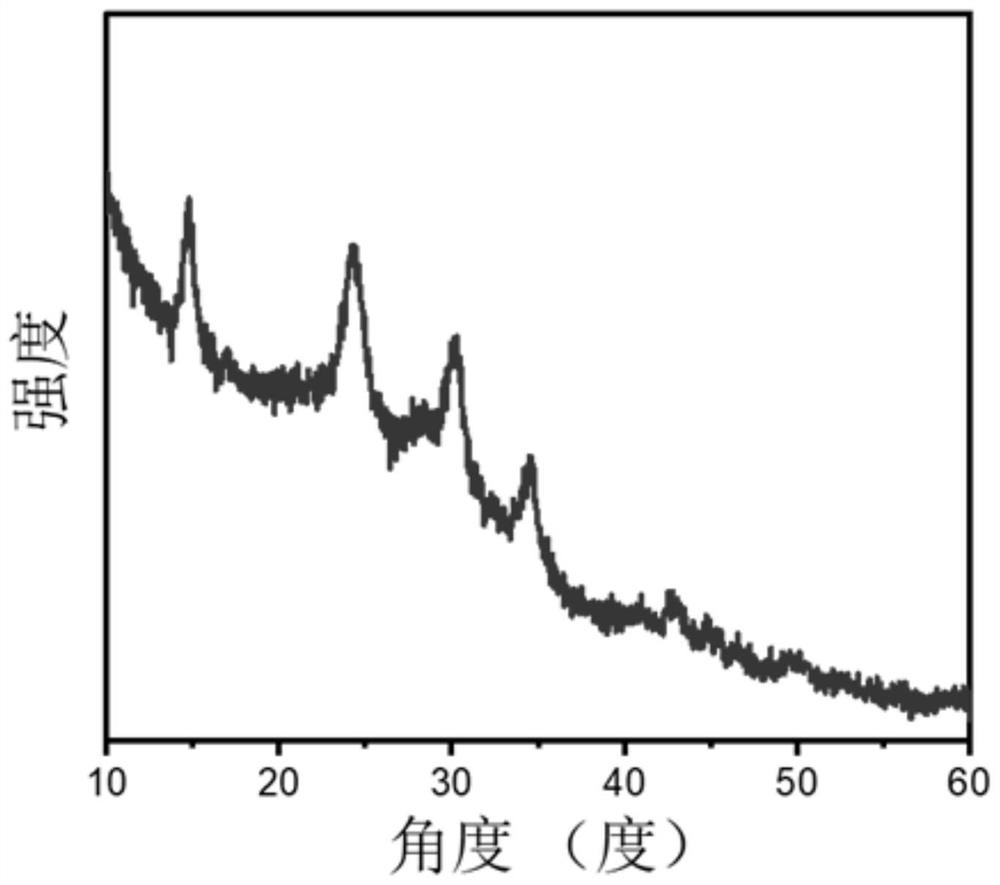

[0030] Cs 2 InBr 5 (H 2 O) The preparation method of the material is: first, cesium acetate and indium acetate are stirred and mixed according to the required amount, ensuring that the mol ratio of cesium and indium is 0.9:0.45, then adding 1-octadecene, oleic acid, oleylamine, and stirring Mix and apply vacuum at 100-115°C for 40-90 min. Then, blow nitrogen, raise the temperature to 170-190°C at 4-8°C / min, inject trimethylbromosilane at 175±5°C, and when the temperature reaches 180-190°C, quickly ice-bath and cool to room temperature. Finally, centrifuge at 9000±1500 rpm for 5-30 minutes to remove the supernatant, then wash with toluene 1-4 times, and centrifuge at 10000±500 rpm for 10±6 minutes to remove the supernatant. Crush the precipitate and apply it on the surface of the attachment to fully expose it to saturated water vapor, keep it for 3 minutes, then disperse the precipitate in n-hexane, centrifuge at 6000±1000 rpm for 10±6 minutes to remove the precipitate, and ...

Embodiment 1

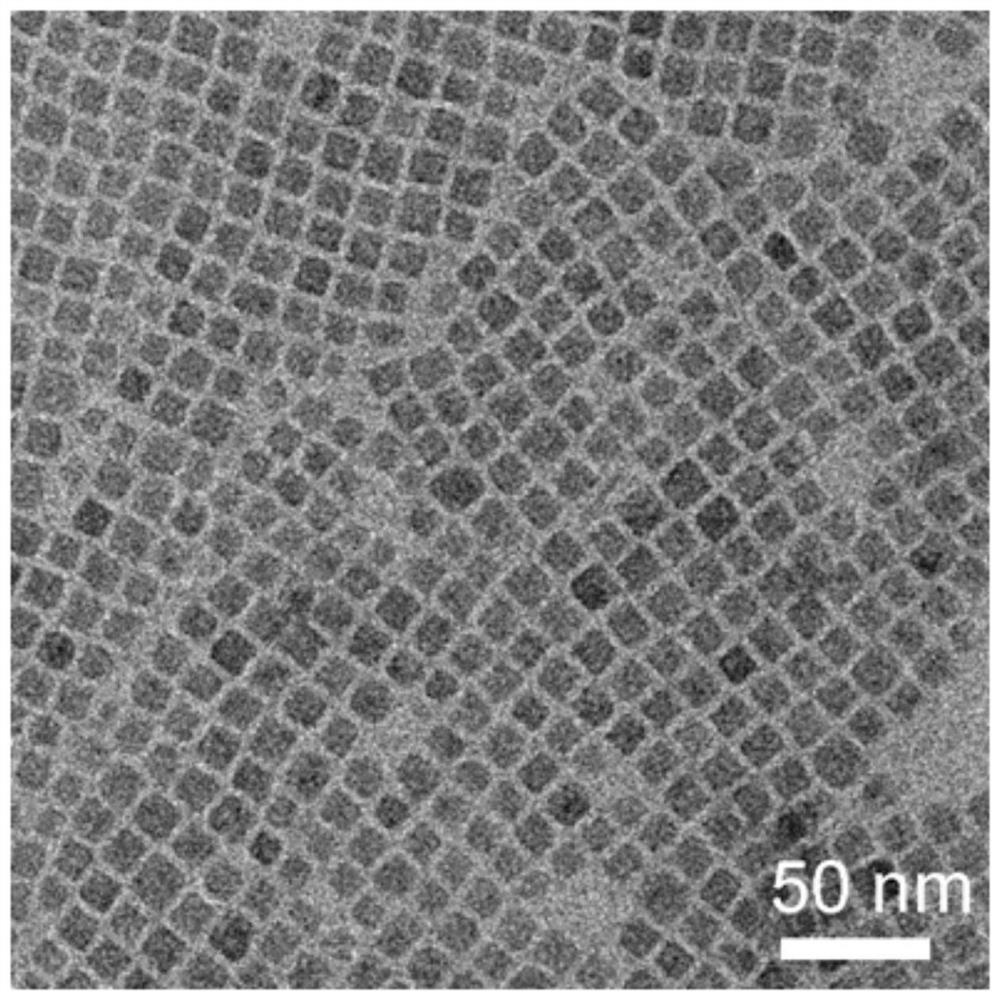

[0034] First, add 96.0 mg of cesium acetate, 131.0 mg of indium acetate and 13.5 mg of antimony acetate into a 50 ml flask, then add 10 ml of 1-octadecene, 2.9 ml of oleic acid, and 0.65 ml of oleylamine, Stir and mix, vacuumize at 105°C for 1h; then, pass nitrogen gas, raise the temperature to 175°C at 4-8°C / min, inject 0.45ml of trimethylchlorosilane into the flask, and when the temperature reaches 185°C, quickly ice-bath , cooled to room temperature; finally, centrifuge the contents of the flask at 10,000 rpm for 10 minutes to remove the supernatant, crush the precipitate and apply it on the surface of the attachment to fully expose it to saturated water vapor, keep it for 3 minutes, and then Wash once with toluene, centrifuge at 10,000 rpm for 5 minutes, remove the supernatant again, and then disperse the precipitate in n-hexane; centrifuge at 5,000 rpm for 5 minutes to remove the precipitate, and the average side length is about 13nm Cs 2 InCl 5 (H 2 O): Sb nanocrystal...

Embodiment 2

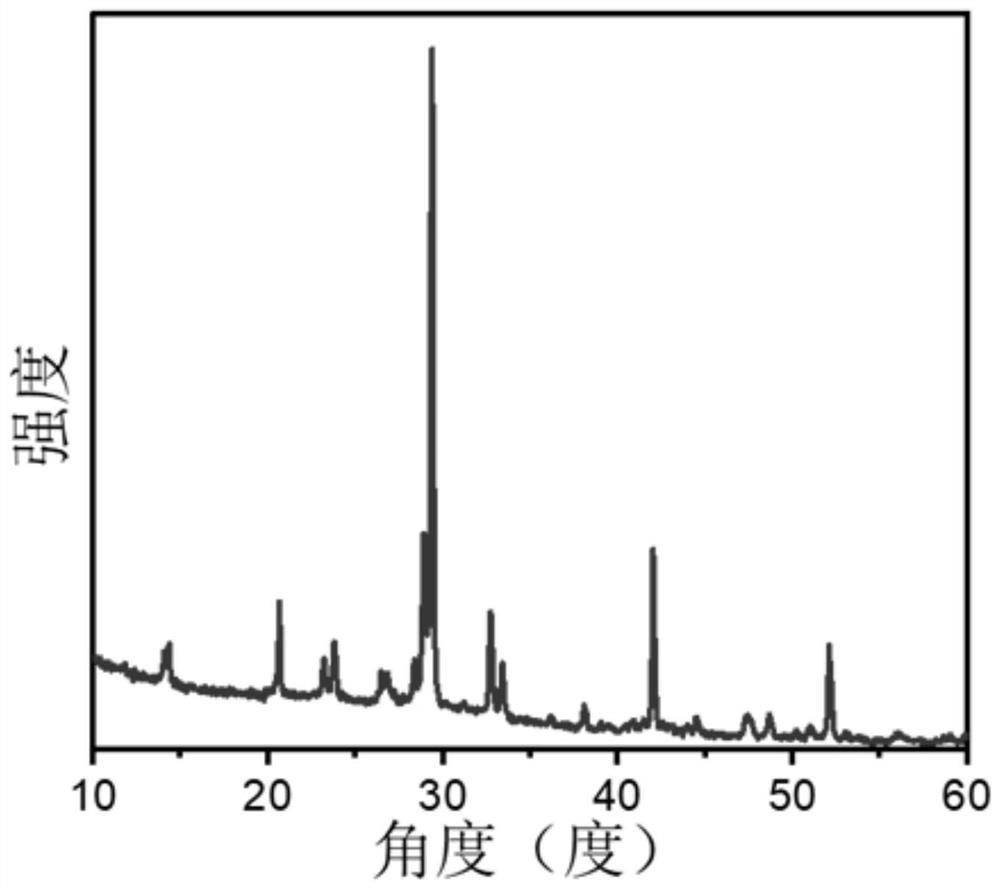

[0036] First, add 172.0 mg of cesium acetate, 131.0 mg of indium acetate and 13.5 mg of antimony acetate into a 50 ml flask, then add 10 ml of 1-octadecene, 2.9 ml of oleic acid, and 0.65 ml of oleylamine, Stir and mix, vacuumize at 105°C for 1h; then, pass nitrogen gas, raise the temperature to 175°C at 4-8°C / min, inject 0.45ml of bromotrimethylsilane into the flask, when the temperature reaches 185°C, quickly ice-bath , cooled to room temperature; finally, the contents of the flask were centrifuged at 10,000 rpm for 10 minutes to remove the supernatant; then washed once with toluene, and then centrifuged at 10,000 rpm for 5 minutes to remove the supernatant, and the precipitate Crush and apply on the surface of the attachment to fully expose to saturated water vapor, keep for 3 minutes; finally, disperse the precipitate in n-hexane, and centrifuge at 5000 rpm for 5 minutes to remove the precipitate, and the average side length is about 38nm Cs 2 InBr 5 (H 2 O): Sb nanocry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com