Boron nitride nanosheet/gold nanocluster composite material and its preparation and its application in biological analysis

A gold nanocluster and composite material technology, which is applied to boron nitride nanosheet/gold nanocluster composite material and its preparation method and application field in biological analysis, can solve problems such as application that have not been reported in literature, and achieve water solubility. Low, reproducible, and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

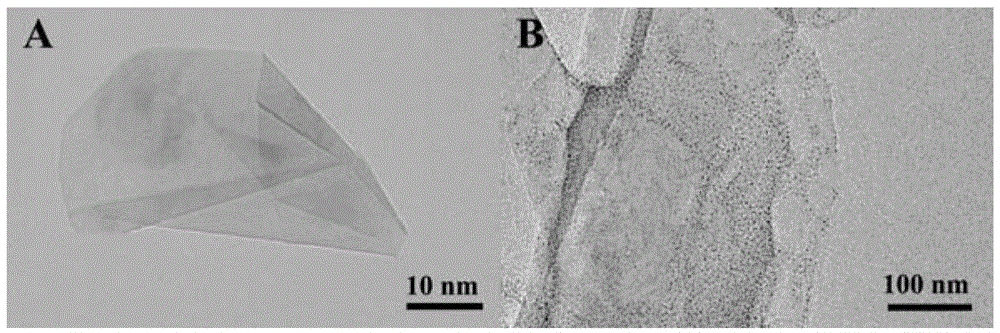

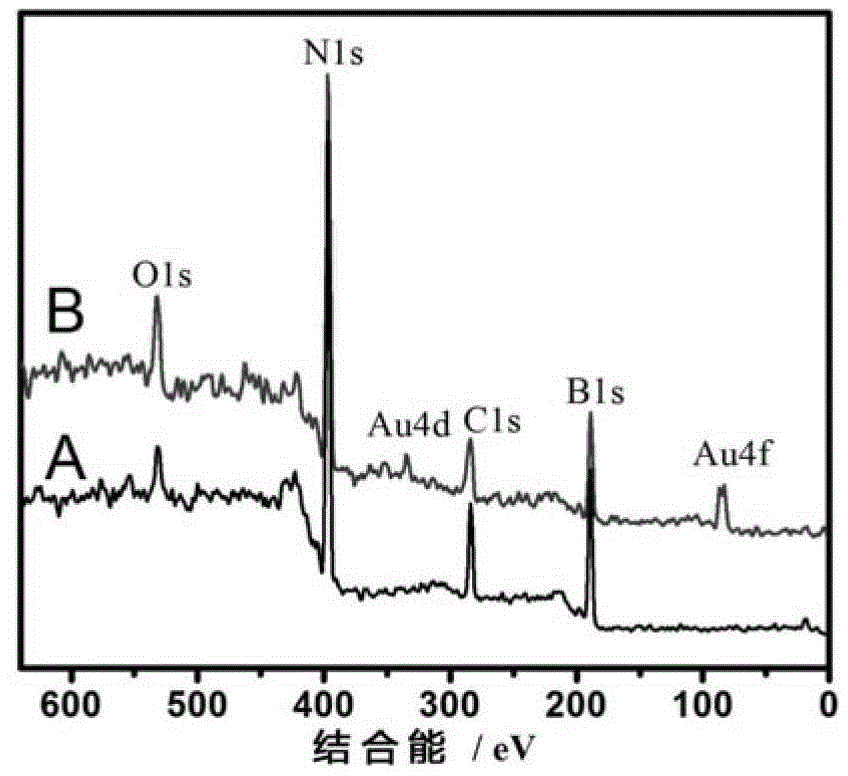

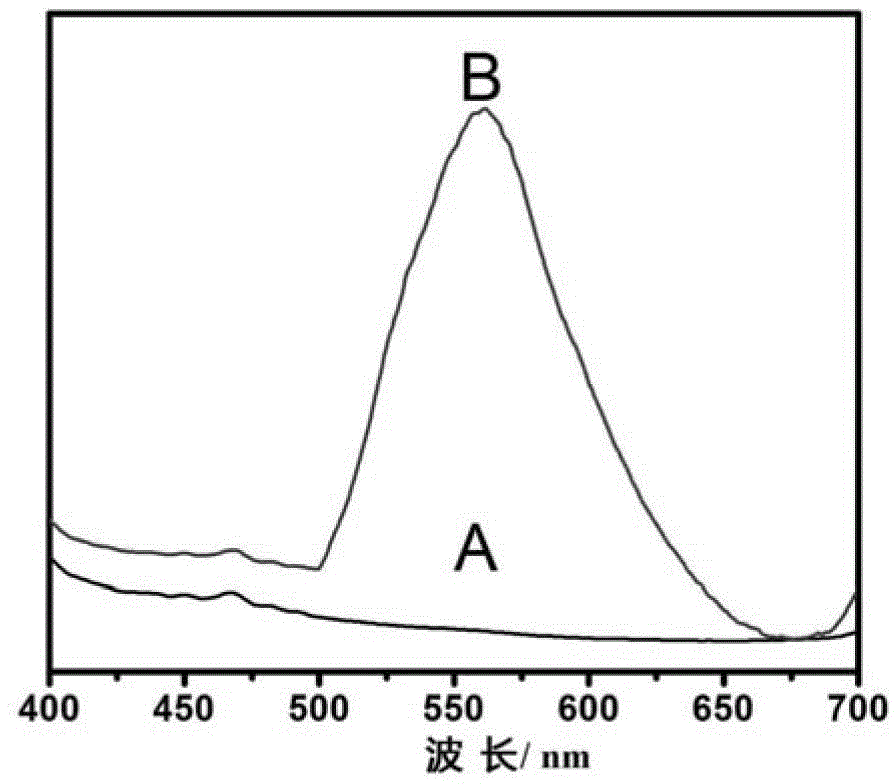

[0023]Embodiment 1. Preparation of the composite material of boron nitride nanosheet / gold nanocluster

[0024] Weigh 100 milligrams of hexagonal boron nitride powder, disperse in 50 milliliters of diethylene glycol diacrylate (PDDA, concentration is 1 milligram per milliliter) in the aqueous solution of phthalate, pass through probe type ultrasonic instrument (VC-750, 20 kHz, 750W, 30% amplification, US Sonics&Materials company) ultrasonic stripping for 4 hours. After the dispersion was left for 24 hours, centrifuge at 2000 rpm for 20 minutes, take 40 ml of the supernatant for later use, use 10 ml of the above supernatant and centrifuge at 10,000 rpm for 10 minutes, and take 1 ml of the lower layer , washed 3 times with secondary water to obtain boron nitride nanosheets (concentration of 1 ± 0.1 mg per ml). Disperse 1 ml of the above-prepared boron nitride nanosheets in 2-3 ml of gold nanocluster solution [Preparation method of gold nanocluster solution: 0.5 ml of HAuCl with ...

Embodiment 2

[0025] Embodiment 2. The preparation of the composite material of boron nitride nanosheet / gold nanocluster

[0026] Change "100 mg of hexagonal boron nitride powder" in Example 1 to "200 mg of hexagonal boron nitride powder", and the other conditions of preparation are the same as in Example 1, and the results are the same as in Example 1.

Embodiment 3

[0027] Embodiment 3. Preparation of the composite material of boron nitride nanosheets / gold nanoclusters

[0028] "Dispersed in the aqueous solution of 50 milliliters of diethylene glycol diacrylate of phthalate" of embodiment 1 was changed into "in the aqueous solution of 100 milliliters of diethylene glycol diacrylate of phthalate", prepared Other conditions are with embodiment 1, and result is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com