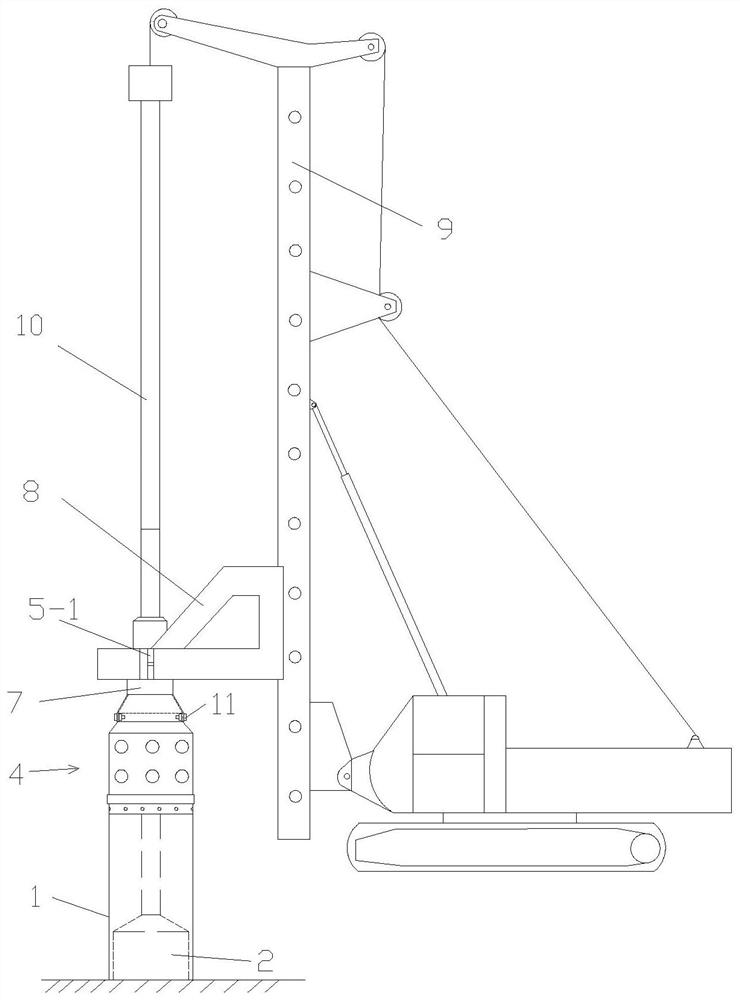

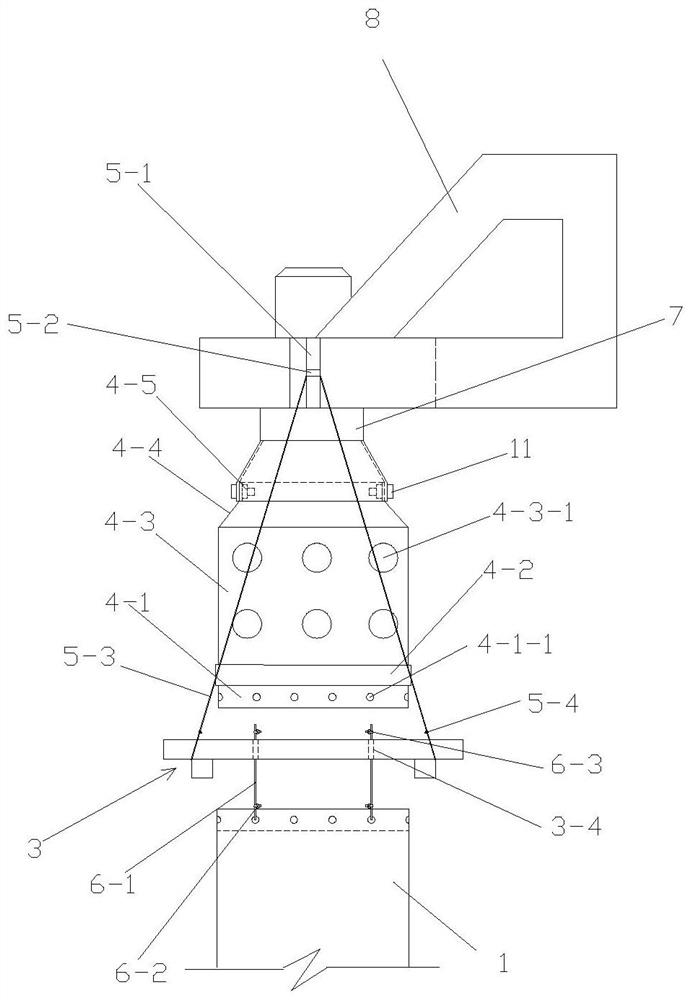

A Hole Forming Method Using Steel Casing Cooperating with Rotary Drilling in Complicated Strata

A technology of complex formations and steel casings, applied in drilling equipment and methods, rotary drilling, percussion drilling, etc., can solve the problems of drilling sticking, short pile-forming period, uneconomical, etc., to avoid Contact damage, good hole quality, convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] Step 3035, remove the connection of the i-th section of steel casing and casing lowering power member 4;

[0129] In step 40D, the method described in steps 406 to 407 is repeated until the bottom of the installed steel casing passes through the second

[0150] The particle size of the crushed stone in step 40B is less than 25 mm.

[0152] In this embodiment, the upper formation is a water-rich formation.

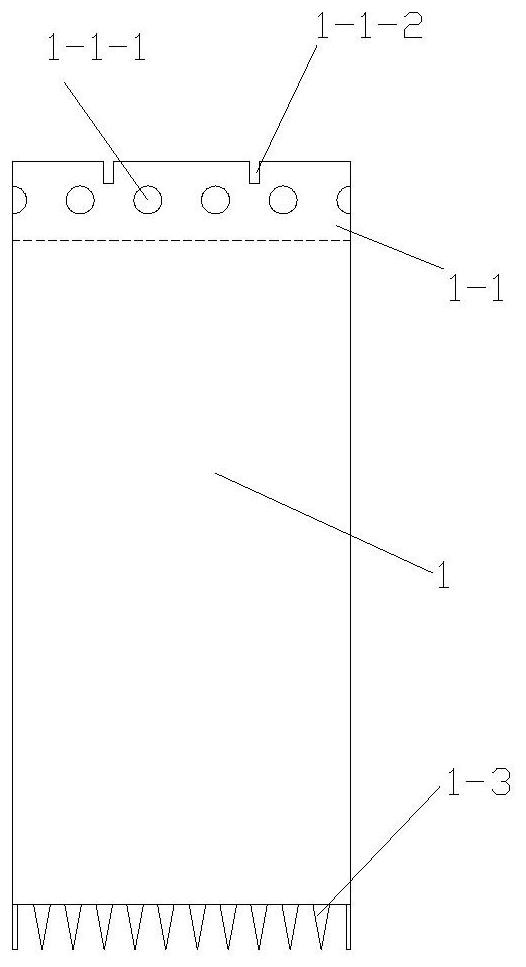

[0155] In this embodiment, in actual use, the length of the last section of the steel casing is adjusted according to the design depth of the bored pile.

[0156] In this embodiment, during actual use, the first section of the steel sleeve 1 and the i-th section of the steel sleeve are made of Q235 steel plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com