Steam turbine-boiler decoupling system and method for improving peak regulation capacity of pure condensing thermal power generating unit

A thermal power unit and peak-shaving technology, which is applied in the direction of machines/engines, mechanical equipment, steam turbines, etc., can solve the problems of limiting the unit’s peak-shaving capability, the inability to further reduce the load rate, and the low and stable combustion load of the boiler, so as to reduce coal consumption The effect of increasing the peak load range and flexibility, improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

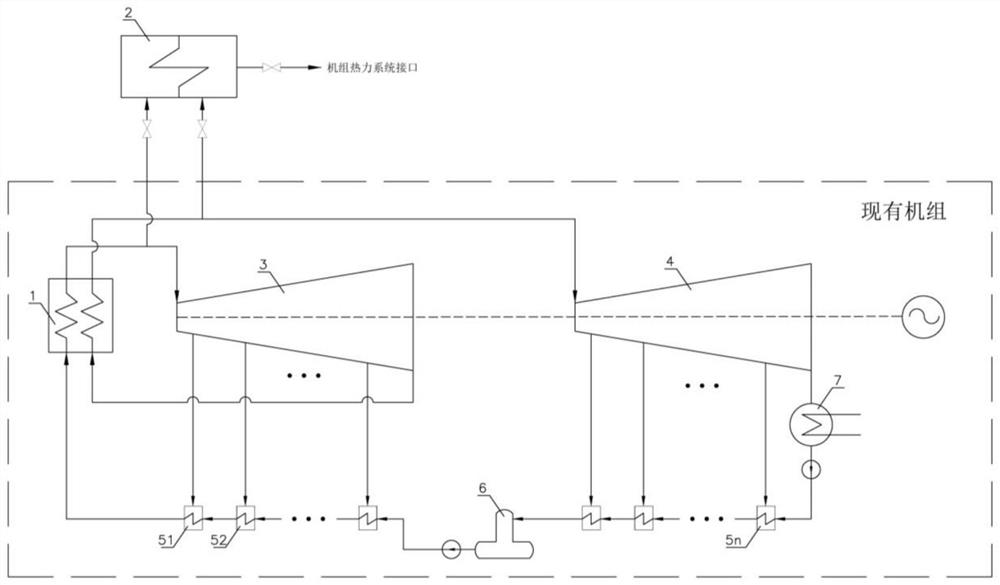

[0038] The rated capacity of the steam turbine unit is 350MW, and the unit is equipped with a heat storage module.

[0039] The main steam pipe and reheat steam pipe of the steam turbine are respectively connected to the inlet of the heat storage module, and the outlet of the heat storage module is respectively connected to the inlet pipe of the boiler economizer and the outlet pipe of the condenser of the steam turbine unit. Such as figure 2 As shown, when the unit participates in power grid peak regulation and needs to reduce the output of the unit to 30% load, set the boiler to run at 50% load, extract part of the main steam from the main steam pipe before entering the high-pressure cylinder of the steam turbine, and enter the heat storage module. After heat exchange, the module mixes with high-pressure feed water and enters the boiler economizer; at the same time, part of the reheat steam is extracted from the reheat steam pipe before entering the medium-pressure cylinder...

Embodiment 2

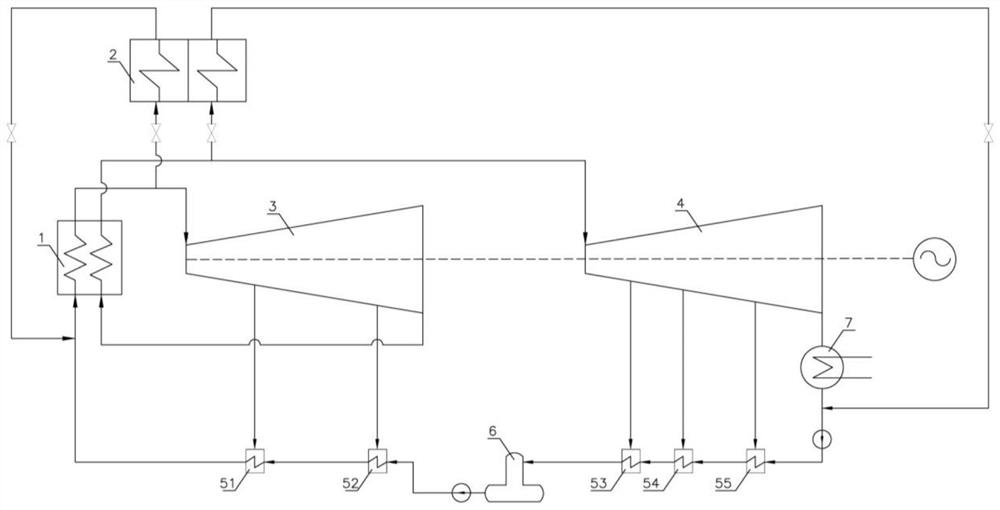

[0042] The rated capacity of the steam turbine unit is 1000MW, and the unit is equipped with a heat storage module.

[0043] The main steam pipe and reheat steam pipe of the steam turbine are respectively connected to the inlet of the heat storage module, and the outlet of the heat storage module is respectively connected to the inlet pipe of the boiler economizer and the 3rd, 4th, and 5th stage steam extraction pipes. Such as Figure 4 As shown, when the unit participates in power grid peak regulation and needs to reduce the output of the unit to 25% load, set the boiler to run at 35% load, extract part of the main steam from the main steam pipe before entering the high-pressure cylinder of the steam turbine, and enter the heat storage module. After heat exchange, the module mixes with high-pressure feed water and enters the boiler economizer; at the same time, part of the reheat steam is extracted from the reheat steam pipe before entering the medium-pressure cylinder of the...

Embodiment 3

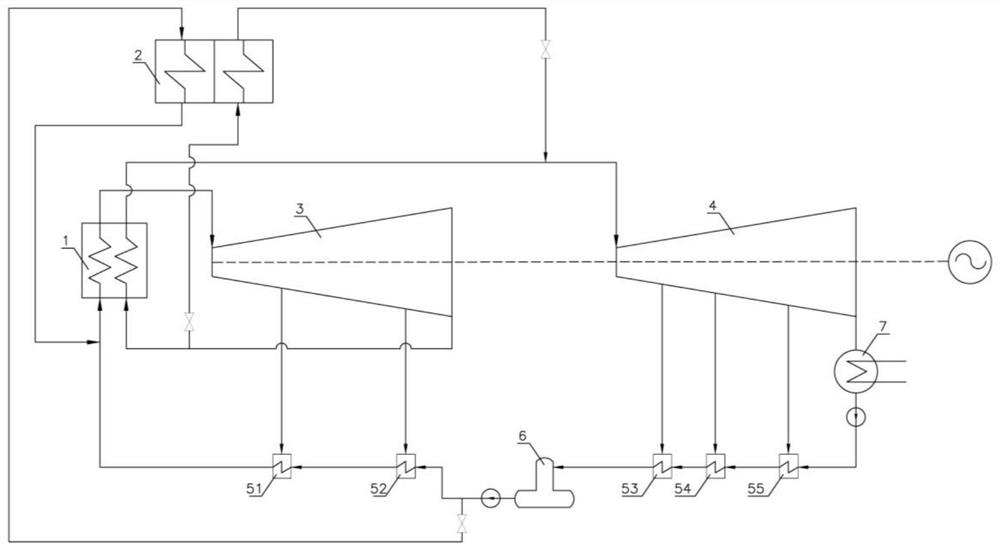

[0046] The rated capacity of the steam turbine unit is 2x660MW. The unit is equipped with a heat storage module and a peak steam turbine for peak regulation. The capacity of the peak steam turbine is 200MW.

[0047] The main steam pipe and the reheat steam pipe of the steam turbine are respectively connected to the inlet of the heat storage module, and the outlet of the heat storage module is connected to the inlet pipe of the boiler reheater and the inlet pipe of the deaerator respectively. Such as Figure 6 As shown, when the unit participates in power grid peak regulation and needs to reduce the output of the unit to 20% load, set the boiler to run at 35% load, extract part of the main steam from the main steam pipe before entering the high-pressure cylinder of the steam turbine, and enter the heat storage module. After heat exchange, the module mixes with the exhaust steam of the high-pressure cylinder and enters the boiler reheater; at the same time, part of the reheat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com