Method for measuring surface roughness of columnar wire rod

A surface roughness and measurement method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of insufficient coverage of the overall object and the inability to meet the rapid detection requirements of enterprises, and achieve the effect of avoiding the interference of liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

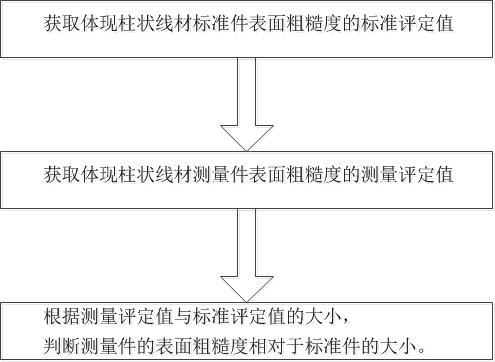

[0036] Such as figure 1 As shown, a method for measuring the surface roughness of a columnar wire, comprising:

[0037] Obtain the standard evaluation value reflecting the surface roughness of the columnar wire standard part;

[0038] Obtain the measurement evaluation value reflecting the surface roughness of the columnar wire measuring piece;

[0039] According to the size of the measured evaluation value and the standard evaluation value, judge the size of the surface roughness of the measured part relative to the standard part.

[0040] The specific steps are:

[0041] Step 1: Obtain the standard evaluation value reflecting the surface roughness of the columnar wire standard part.

[0042] Step 1-1: Hang a heavy object on one end of the cylindrical wire standard, and immerse this end vertically in a long straight U-shaped tube filled with standard liquid.

[0043] Step 1-2: Let the standard piece of columnar wire with a heavy object fall freely, record the time it takes...

Embodiment 2

[0059] This example is a specific application scenario using the method for measuring the surface roughness of a columnar wire provided in Example 1 of the present invention. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the present invention. scope of protection.

[0060] Cut two 15cm long straightened Φ1.80mm steel wire, one steel wire A is fully polished by 120 mesh water abrasive paper, and the other steel wire B is fully polished by 800 mesh water abrasive paper. Hang a copper ball with a radius of 3mm at a place 5cm below one end of the steel wire A with a Φ0.10mm thin steel wire, and dip this end vertically into a U-shaped tube with an inner diameter of 12mm filled with glycerin, the liquid level is 1.5m, and the environment The temperature is 19°C, let it fall freely and start timing at the same time, record the time it takes for the metal ball to fall to the bottom, which is 4.27s. ...

Embodiment 3

[0062] This example is a specific application scenario using the method for measuring the surface roughness of a columnar wire provided in Example 1 of the present invention. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the present invention. scope of protection.

[0063] Cut two 15cm long straightened Φ 2.00mm copper wire, one copper wire C is fully polished by 120 mesh water abrasive paper, and the other copper wire D is fully polished by 1200 mesh water abrasive paper. Hang a copper ball with a radius of 3mm at a place 5cm below one end of the copper wire C with a Φ0.10mm thin steel wire, dip this end vertically into a U-shaped tube with an inner diameter of 12mm filled with ethylene glycol, and the liquid level is 2.5m. The ambient temperature is 19°C, let it fall freely and start timing at the same time, record the time it takes for the metal ball to fall to the bottom, which is 1.08s. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com