Poultry eggshell membrane separation device

A technology for shell membrane separation and poultry eggs, which is applied in the preparation of test samples, etc., can solve the problems of impurities, misjudgment of enzyme content, and poor integrity in the membrane under the shell, and is conducive to enzyme content, accurate data, and pure texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

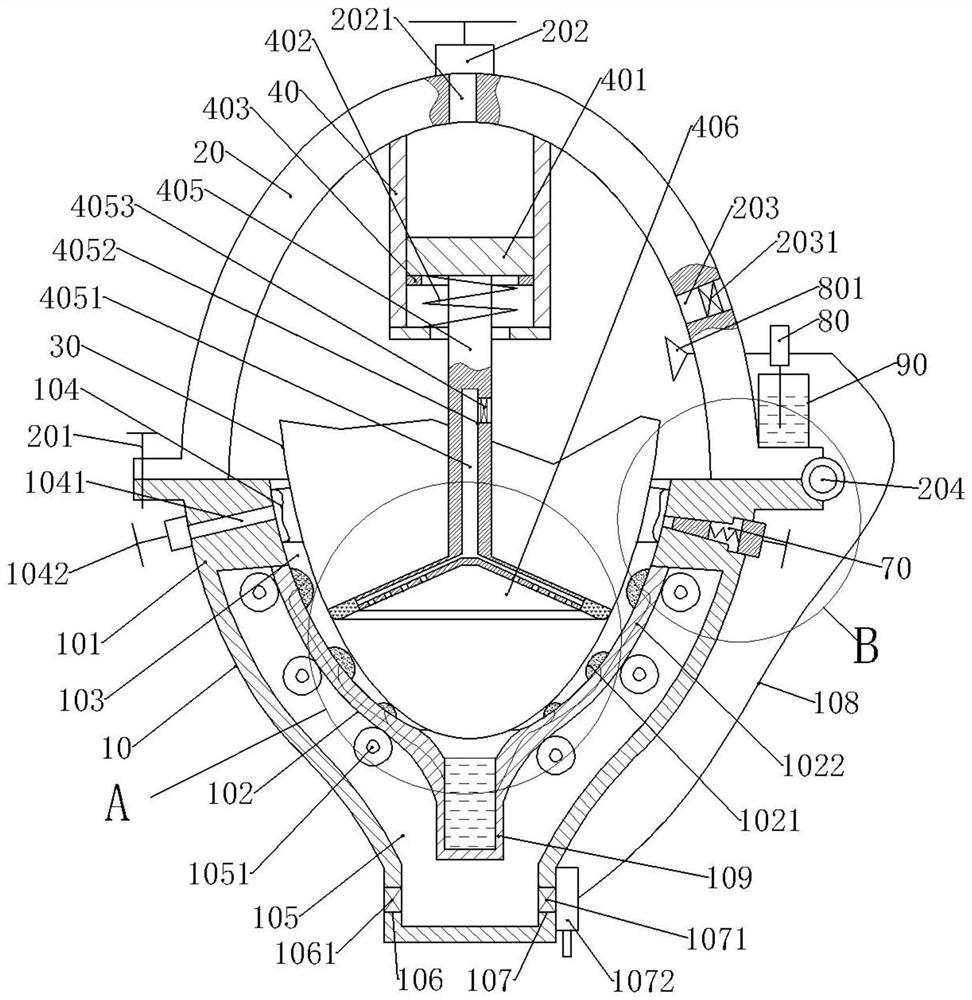

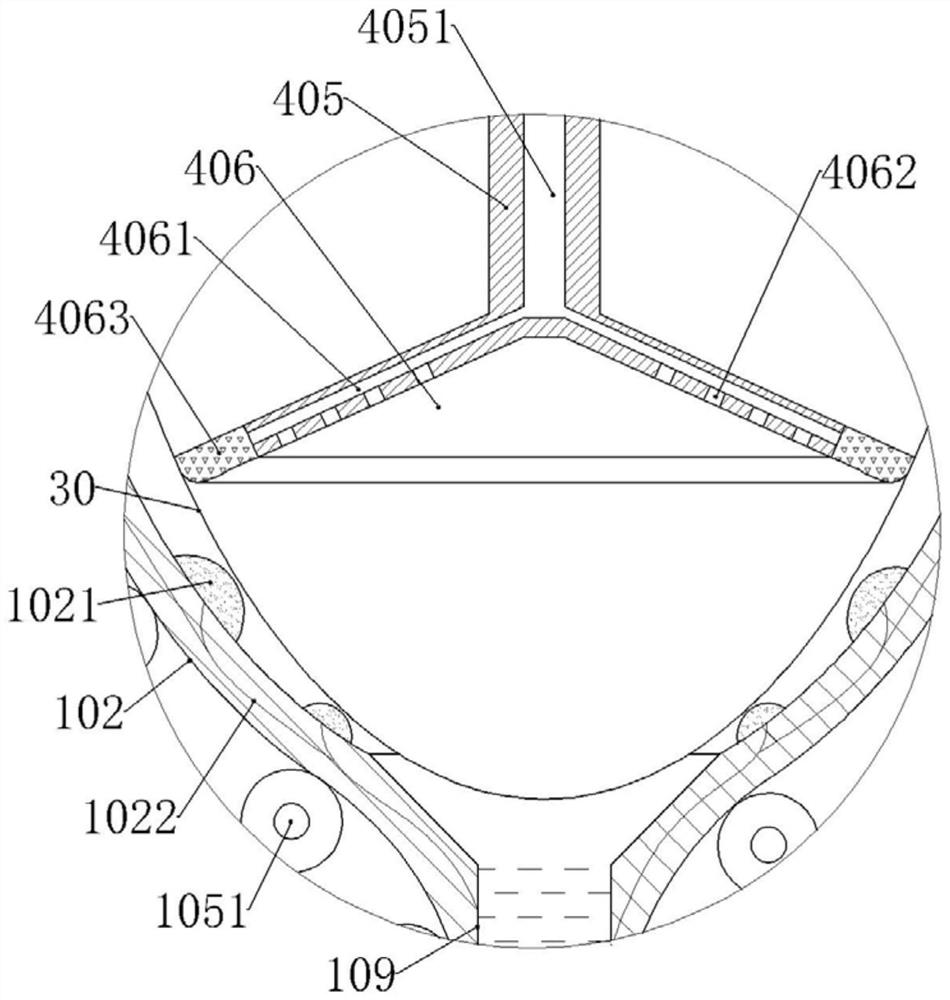

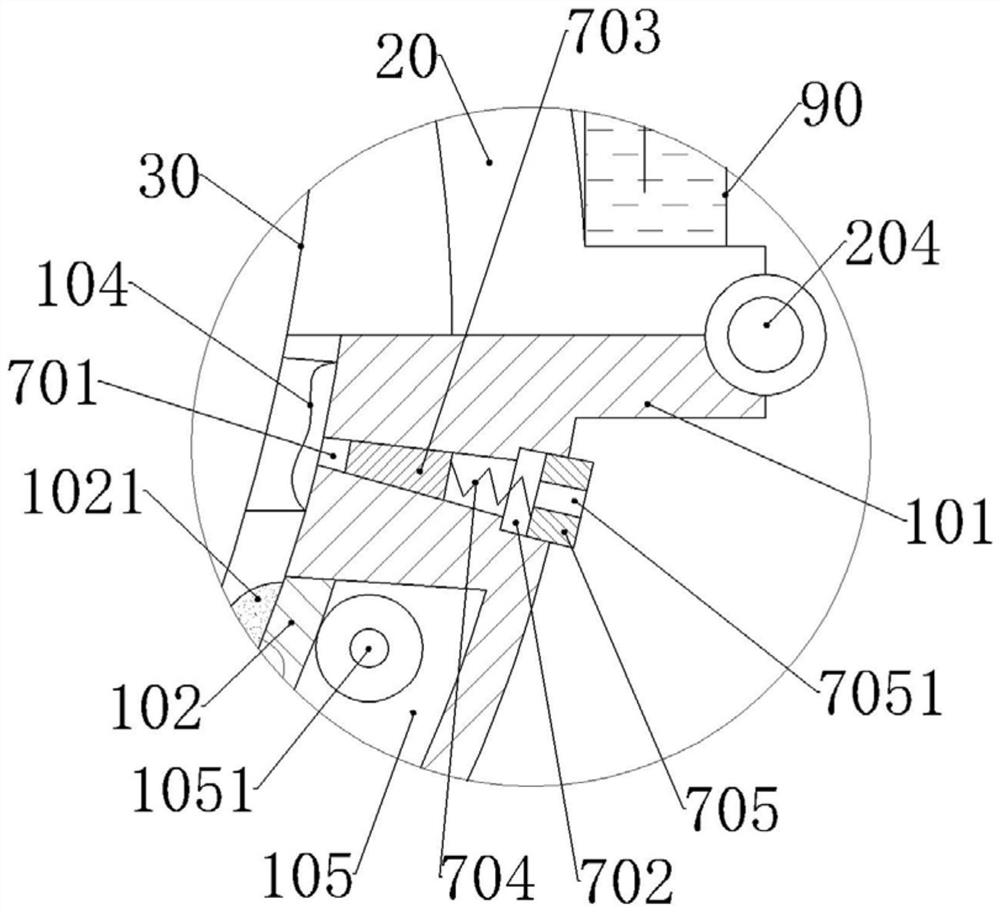

[0030] The reference signs in the accompanying drawings of the specification include: seat body 10, outer shell 101, inner shell 102, soft protrusion 1021, capillary channel 1022, groove 103, annular air bag 104, leak channel 1041, exhaust switch 1042, heating chamber 105, electric heating pipe 1051, air inlet 106, air inlet check valve 1061, air outlet 107, air outlet check valve 1071, first air valve 1072, air pipe 108, water collection tank 109, cover 20, lock 201, The second air valve 202, the third through hole 2021, the second through hole 203, the second one-way valve 2031, the hinge 204, the poultry eggshell 30, the air cylinder 40, the piston 401, the first spring 402, the limit block 403, the push Rod 405, hollow channel 4051, first through hole 4052, first one-way valve 4053, suction cup 406, cavity 4061, suction hole 4062, elastic lower edge 4063, pressure relief device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com