Conductive, Anti-corrosive magnesium titanium oxide catalyst support material

A catalyst carrier and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problems of low activity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] Group A

[0116] To verify the results of the DFT derivation, the disclosed materials were synthesized and tested according to the methods described below.

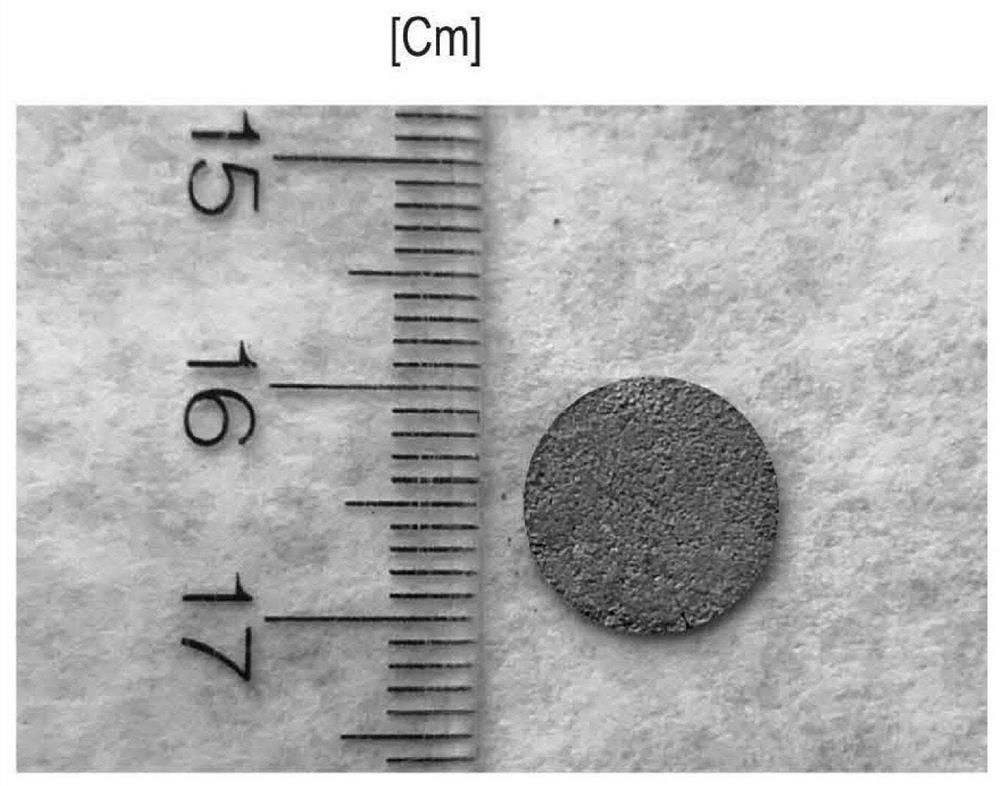

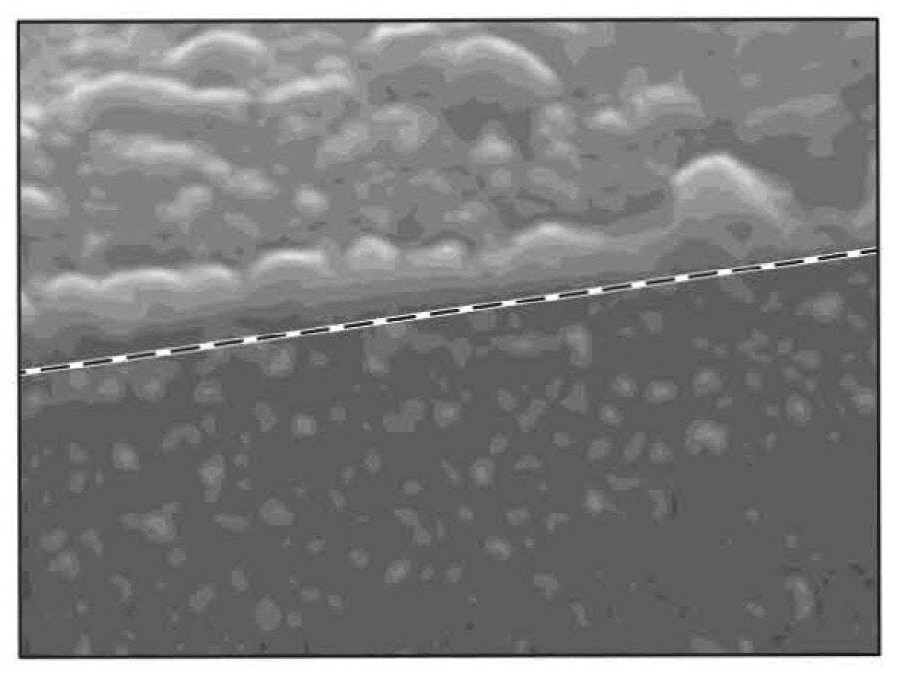

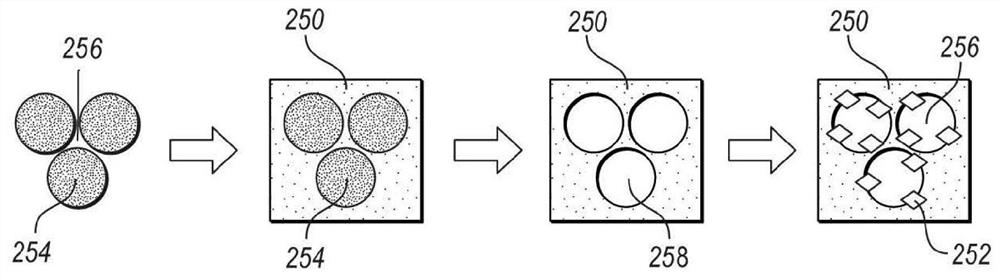

[0117] Use dry MgO, TiO and TiO 2 Powder Mixtures The disclosed materials were synthesized by the following methods. The MgO powder was dried at 120 °C for 2 h in an Ar environment. The dried powder was then mixed with TiO / TiO 2 The powders are mixed to form a mixture. The mixture was compressed under 3000 psi uniaxial load into pellets measuring about 12 mm in diameter and about 2 mm in thickness. Freshly pressed pellets have a light gray color. The compacted pellets were then loaded into Al 2 o 3 Crucible and heated to vacuum environment (10 -3 Torr) for reactive sintering (for example at 1450° C.) for 10 hours. After sintering, the pellets appear black with a bluish tinge. The method was used to prepare five batches of pellets, each batch containing three to four pellets.

[0118] Five sintered pell...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap