Supporting roller quick-changing support and quick-changing method thereof

A technology on support rolls and brackets, which is applied in the direction of metal rolling racks, metal rolling, manufacturing tools, etc., can solve the problem that the upper support roll cannot be quickly positioned and reinstalled, so as to save replacement time, simplify production, and avoid safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

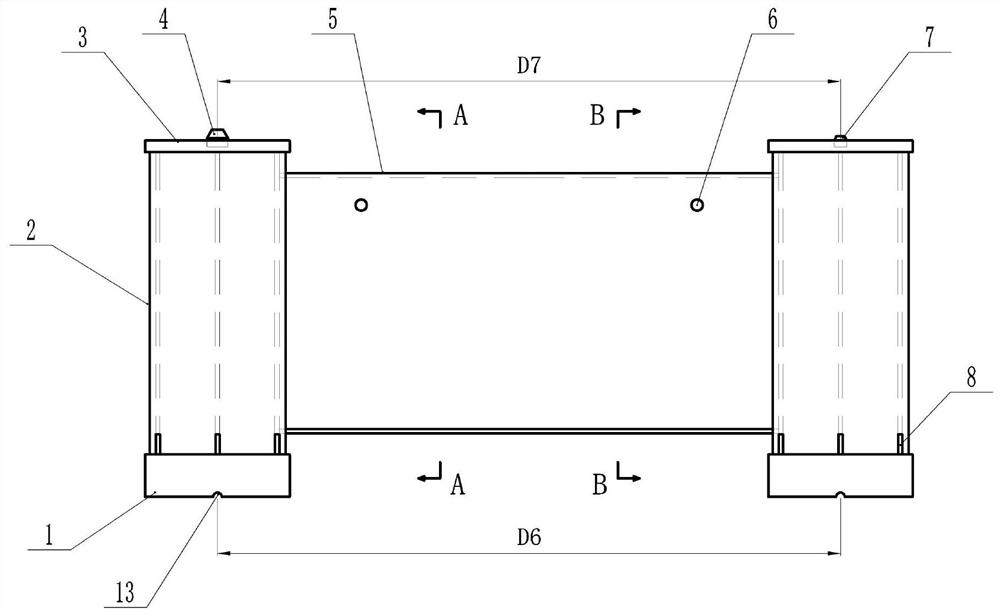

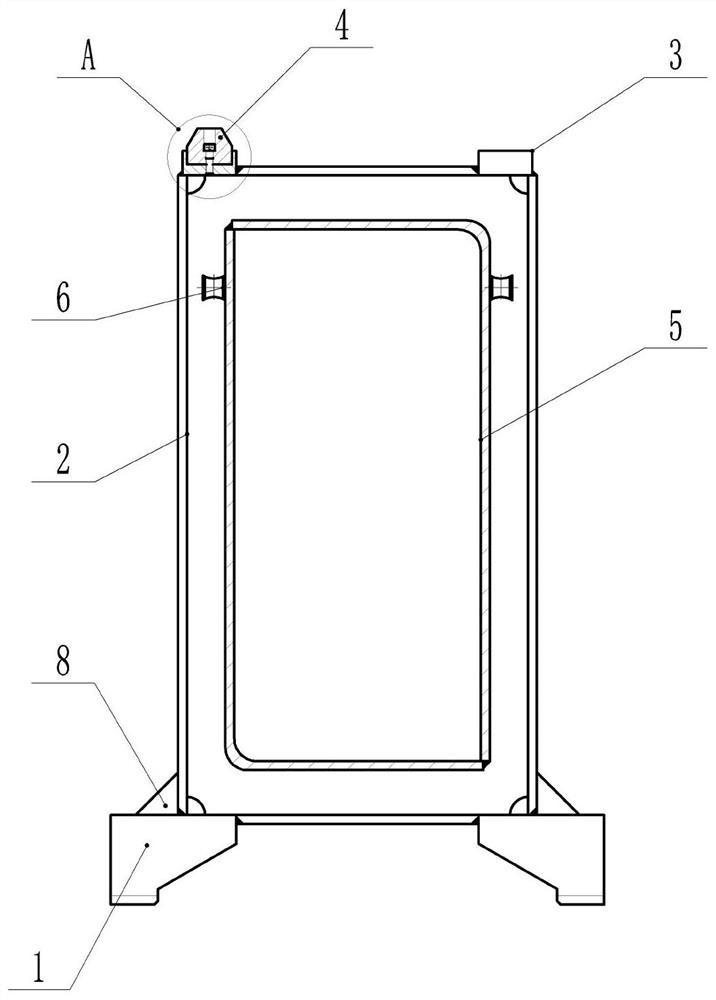

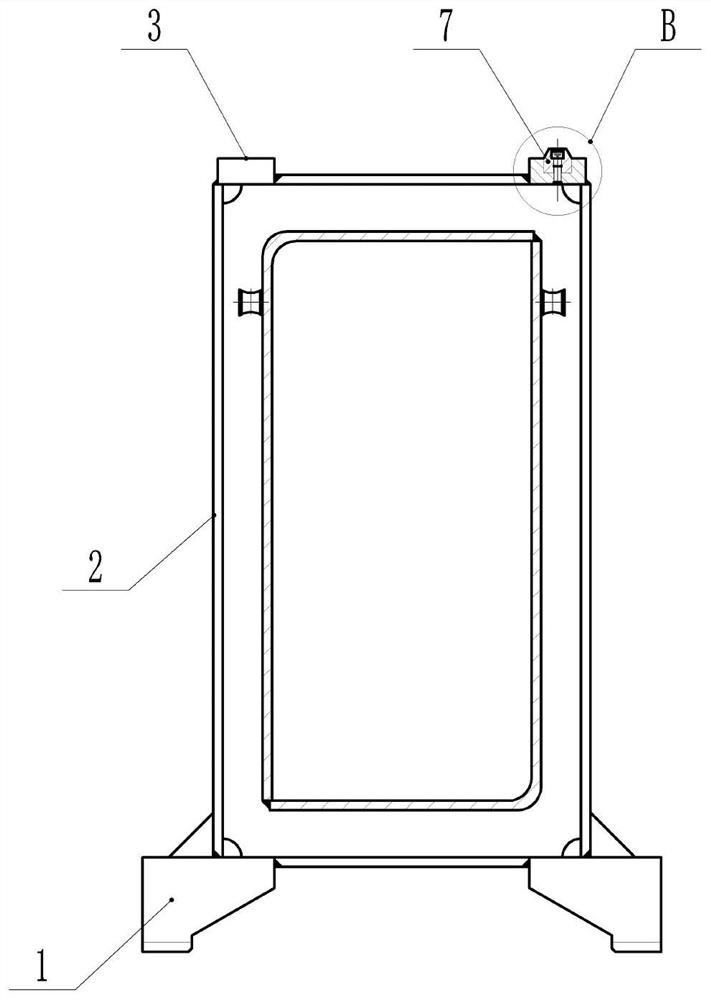

[0032] Such as Figure 1 to Figure 6 As shown, this embodiment provides a backup roller quick change bracket, including: an upper positioning assembly, a lower positioning assembly and a connecting assembly.

[0033] The lower positioning assembly includes bases 1 arranged in pairs, and a hole for positioning with the lower support roller 11 is provided on the bottom surface of the base 1. The hole is a semicircular hole 13, and the semicircular hole 13 is used to match with the positioning pin on the top surface of the lower support roller 11. .

[0034] The connecting component is arranged between the lower positioning component and the upper positioning component, and is used for connecting the upper positioning component and the lower positioning component. The connection assembly includes support frames 2 arranged in pairs. The support frames 2 are welded by six steel plates, front, rear, left, right, upper and lower. The support frames 2 are in the shape of a cuboid. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com