Production method for controlling isometric crystal of high-alloy heat-resistant stainless steel continuous casting billet

A technology of heat-resistant stainless steel and continuous casting slabs, which is applied in the field of axial grain control, can solve the problems that high-alloy heat-resistant stainless steel cannot be used, and achieve the effects of stable slab quality, uniform structure, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Present embodiment 1Cr25Ni20Si2 stainless steel, the mass percent of its chemical composition is:

[0042] C: 0.065%, Si: 1.72%, Mn: 1.30%, P: 0.025%, S: 0.002%, Cr: 25.20%, Ni: 19.30%, and the rest are Fe and unavoidable impurities.

[0043] The billet specification of this embodiment is 200mm * 1250mm.

[0044] This embodiment includes the following steps:

[0045] Ⅰ Tundish molten steel superheat

[0046] Control the average superheat degree of tundish steel level to 23°C.

[0047] Ⅱ Casting speed

[0048] The pulling speed is controlled by 1.10m / min.

[0049] Ⅲ Control of Mold Cooling Intensity

[0050] The cooling water for the wide side of the crystallizer is 4100L / min, and the cooling water for the narrow side of the crystallizer is 370L / min.

[0051] Ⅳ Electromagnetic Stirring Parameter Selection

[0052] Electromagnetic stirring parameters are: current 1300A, frequency 1.5Hz.

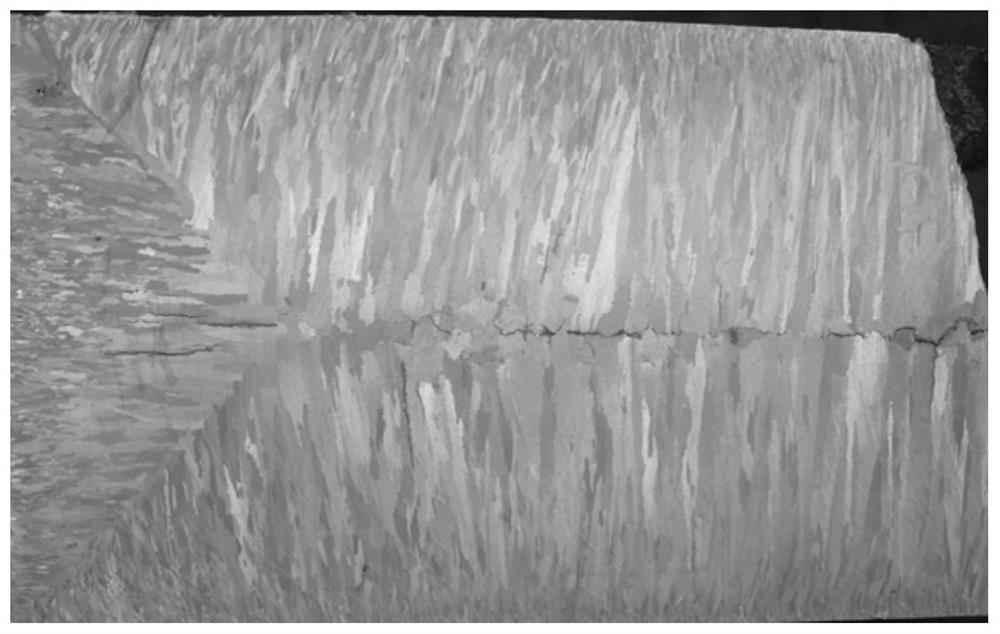

[0053] The slab obtained in this embodiment is as figure 2 shown. Depend o...

Embodiment 2

[0056] Present embodiment 1Cr25Ni20Si2 stainless steel, the mass percent of its chemical composition is:

[0057] C: 0.055%, Si: 1.63%, Mn: 1.22%, P: 0.025%, S: 0.001%, Cr: 25.12%, Ni: 19.18%, and the rest are Fe and unavoidable impurities.

[0058] The billet specification of this embodiment is 200mm * 1500mm.

[0059] The embodiment of the method for controlling high-alloy heat-resistant stainless steel 1Cr25Ni20Si2 continuous casting slab equiaxed crystal comprises the following steps in sequence:

[0060] Ⅰ Tundish molten steel superheat

[0061] Control the average superheat degree of tundish steel level to 18°C.

[0062] Ⅱ Casting speed

[0063] The pulling speed is controlled by 1.00m / min

[0064] Ⅲ Control of Mold Cooling Intensity

[0065] The cooling water for the wide side of the crystallizer is 4000L / min, and the cooling water for the narrow side of the crystallizer is 350L / min.

[0066] Ⅳ Electromagnetic Stirring Parameter Selection

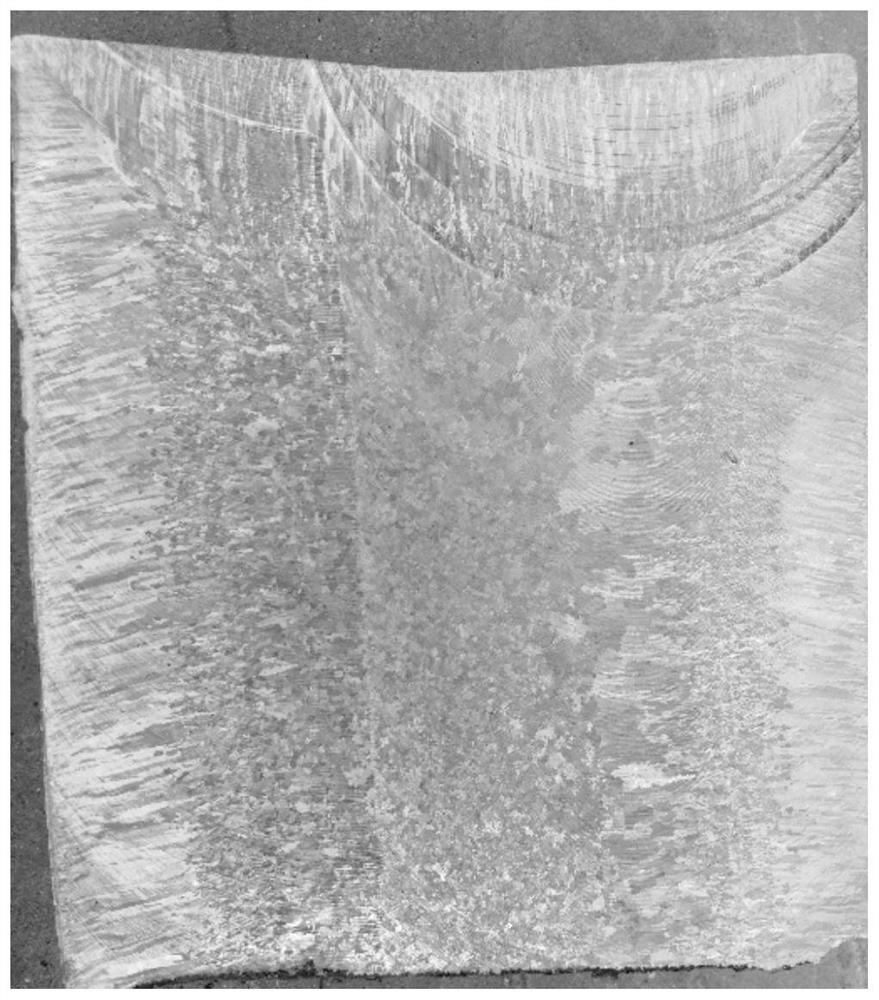

[0067] Electromagnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com