Board thickness-adjustable type frame sawing machine

A technology of frame sawing machine and wood board, which is applied in the field of wood board adjustable thickness frame sawing machine, which can solve the problems of increasing cost and wasting labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

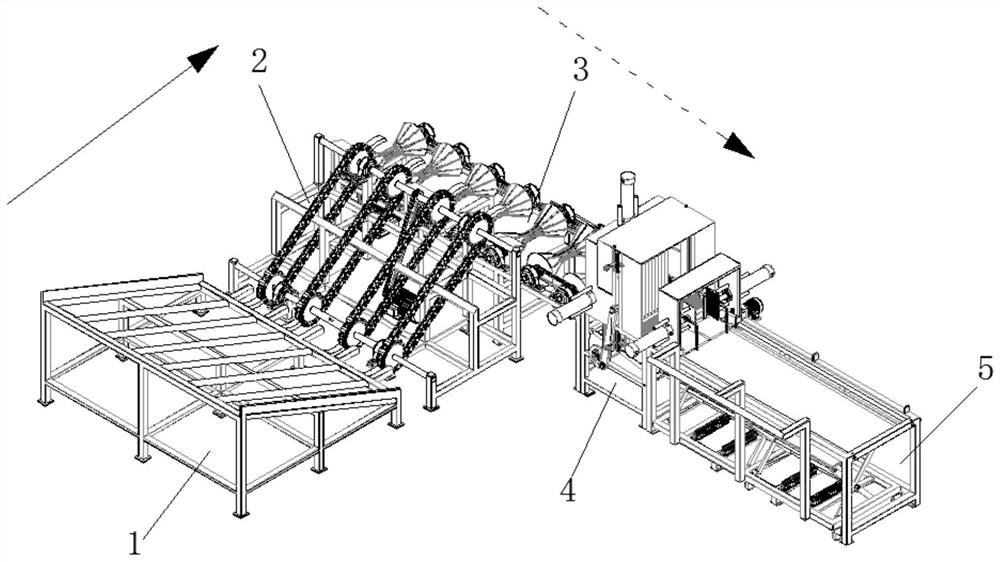

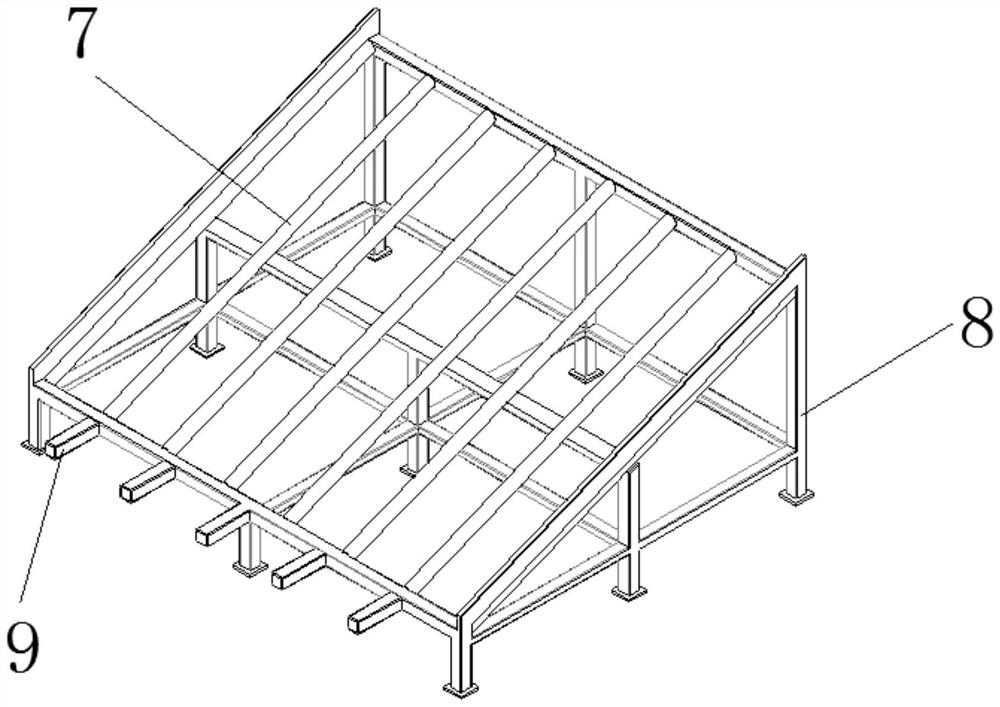

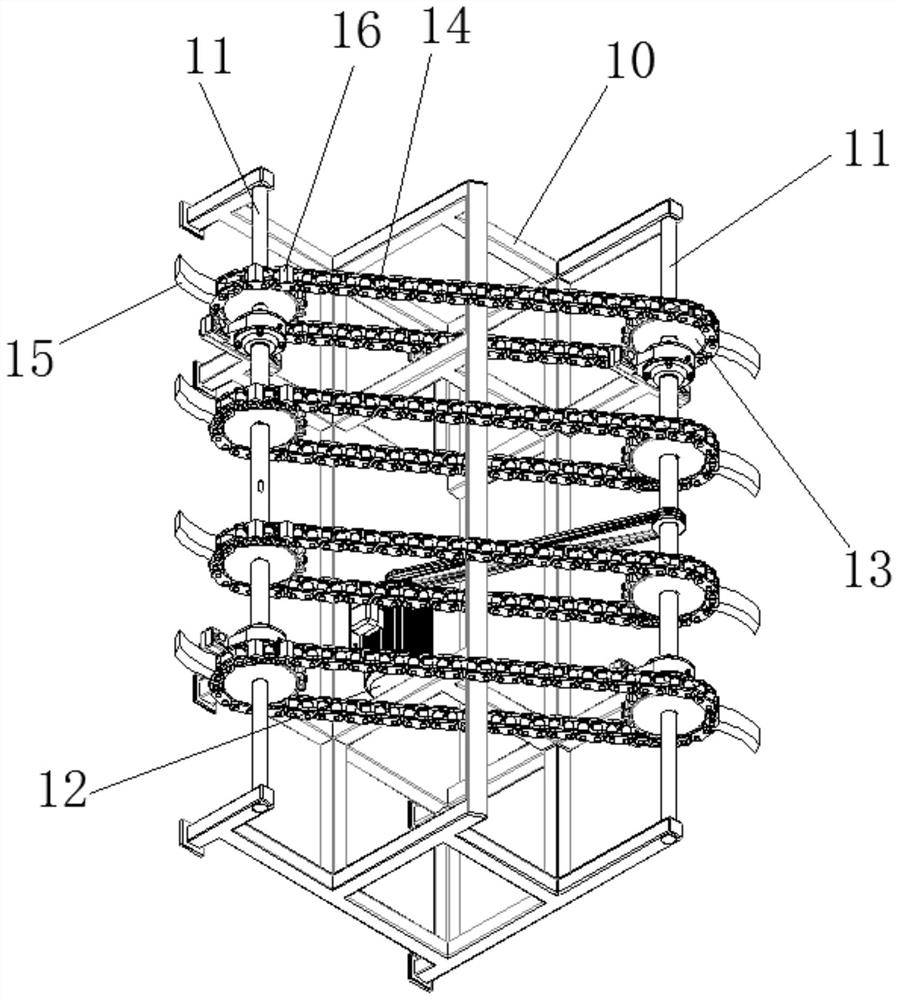

[0051] Such as figure 1 As shown, a frame saw machine with adjustable thickness for wood boards includes a building block frame 1 , a wood removal device 2 , a propulsion device 3 , a clamping and sawing device 4 and a collecting and transporting device 5 . The building block frame 1 is provided with an inclined plane structure in which the timber 6 with the axial direction being the longitudinal direction is rolled forward in the transverse direction by its own gravity, and the wood removal device 2 is located on the front side of the building block frame 1 in the transverse direction, and it hooks The wood 6 rolled down from the building block frame 1 is lifted laterally forward by a preset height. The propulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com