Negative ion environment-friendly coating and preparation method thereof

An environmentally friendly coating and negative ion technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of weak adsorption, not conducive to improving the air purification effect of coatings, etc., to reduce mixed crosslinking agents and improve air purification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

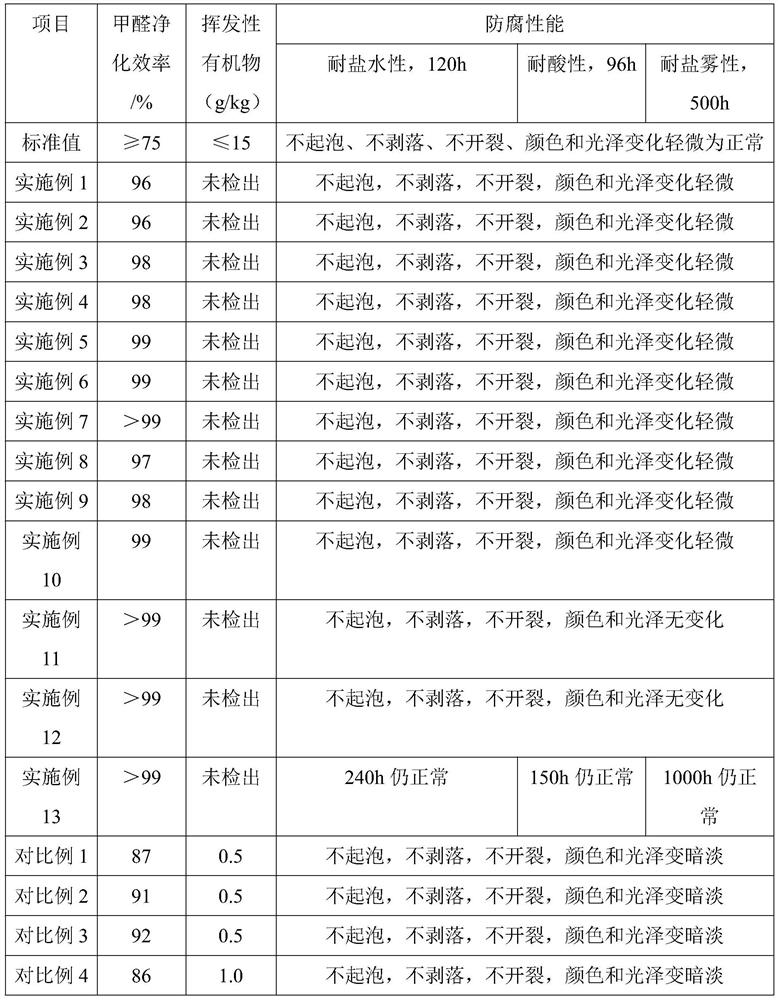

Examples

preparation example 1

[0045] BI 2 O 3 / Activated carbon, prepared in accordance with the following steps: 1.5 kg of 2.5% nitric acid solution and 1.5 kg absolute ethanol were added to the stirrer, and after stirring at 300r / min for 30 min, 1.5 kg of BI (NO) 3 ) · 5h 2 O Add to the stirrer, stirred at 400r / min for 50 min to give a transparent sol, and the transparent sol is placed in the hydrofluoroethylene liner in the hydrothermal reaction kettle, and the polytetrafluoroethylene liner is placed in the hydrothermal reaction kettle. Further, the hydrolymothermal reaction elutabate was removed into the oven, reacted at 120 ° C for 24 h, remove the reaction kettle, and then centrifuate the liquid in the polytetrafluoroethylene insertion, gave a solid product, put the solid product in an oven, at 80 After drying at ° C for 6 h, then polished the solid product, resulting in Bi 2 O 3 / Activated carbon.

preparation example 2

[0047] BI 2 O 3 -Tio 2 / Activated carbon, prepared according to the following steps:

[0048] (1) 1.5 kg of titanate titanate with 4 kg of anhydrous ethanol was added to the agitator, under 200R / min, stirred for 15 min to give a titanium-containing solution;

[0049] (2) At 300 r / min, 1.5 kg of nano activated carbon was added to a titanium-containing solution, stirred for 15 min to give a mixture;

[0050] (3) mixing 1.5 kg of 2.5% nitric acid solution and 1.5 kg of anhydrous ethanol mix well to give a nitrate solution;

[0051] (4) Under stirring conditions of 400R / min, nitrate solution and 1.5 kg of BI (NO) 3 ) · 5h 2 O Add in the mixture, stir after 60min, resulting in a sol;

[0052] (5) In the polytetrafluorine liner in the hydrothermal reaction kettle, the polytetrafluoroethylene linear is placed into a water heat reaction kettle, and then remove the hydrothermal reactor into the oven, at 120 ° C, will The hydrothermal reaction kettle is heated for 24 h, and the polyt...

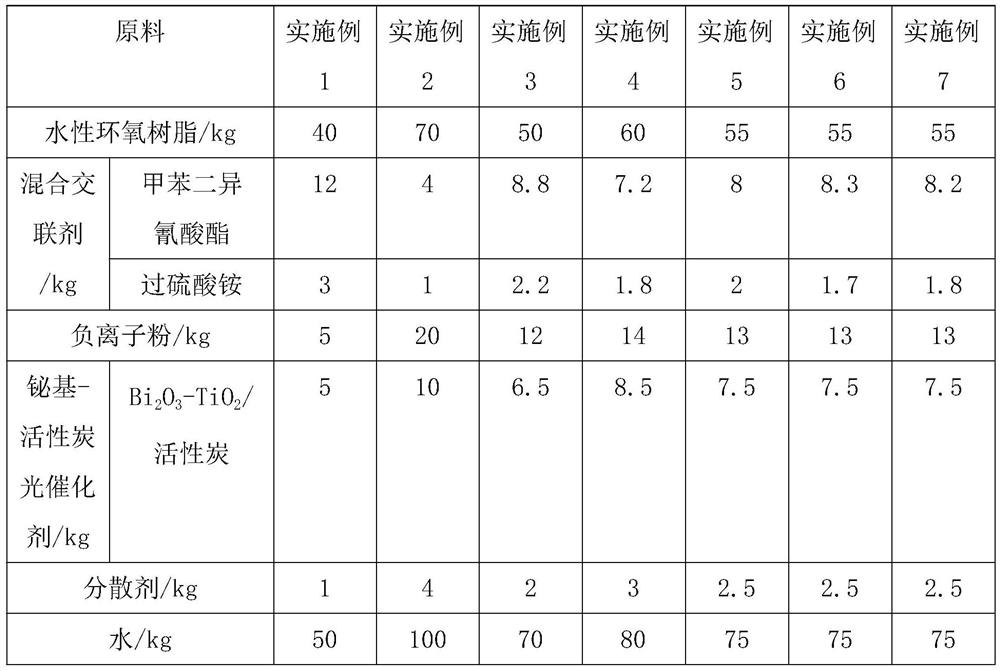

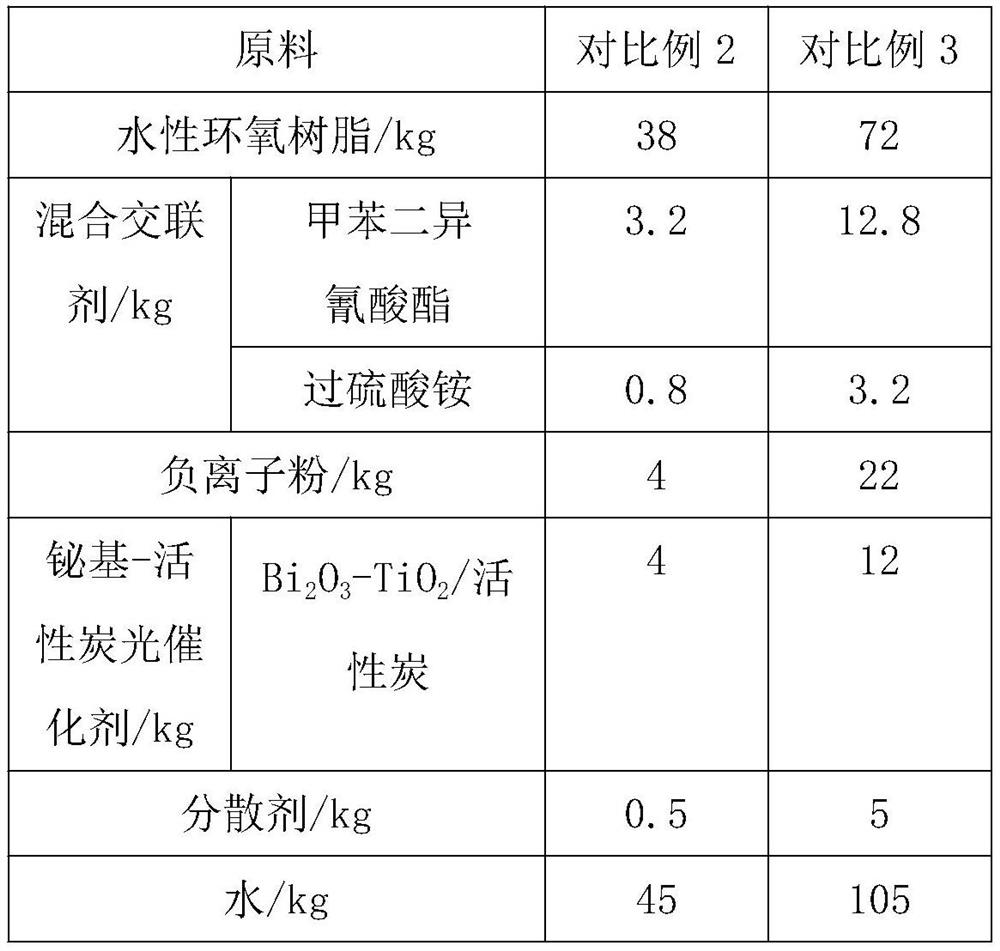

Embodiment 1-7

[0055] As shown in the table, the main difference between Examples 1-7 is different from the ratio of the feedstock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com