Lily-shaped tungsten nitride/tungsten oxycarbide composite material and its preparation method and application

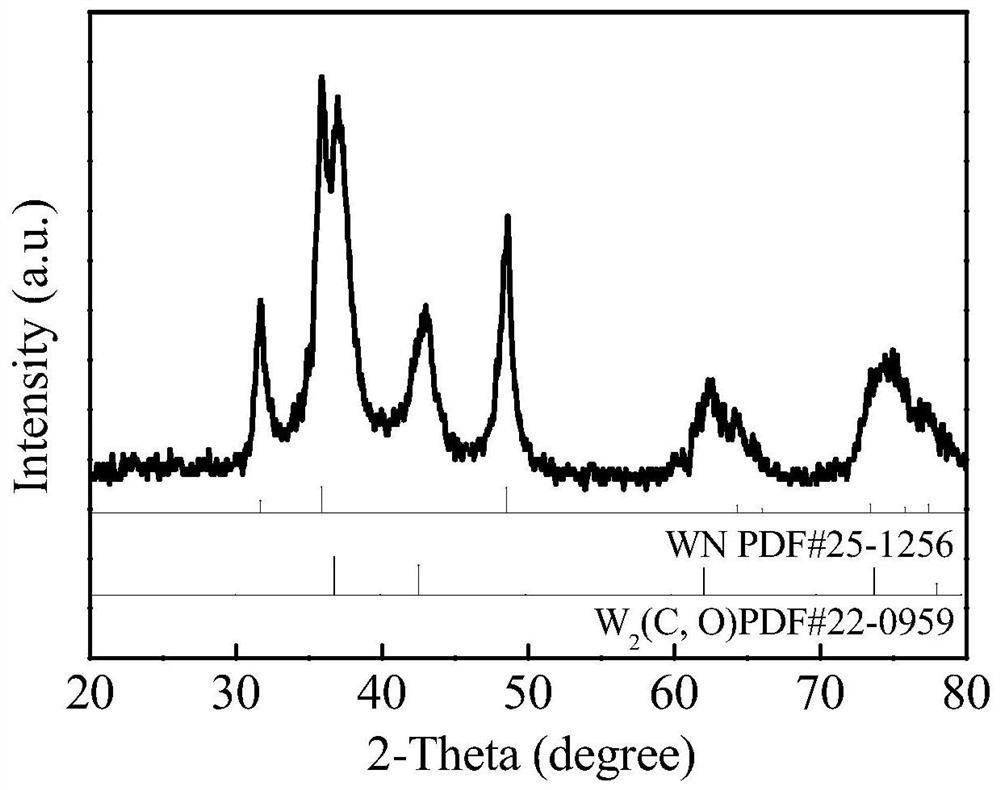

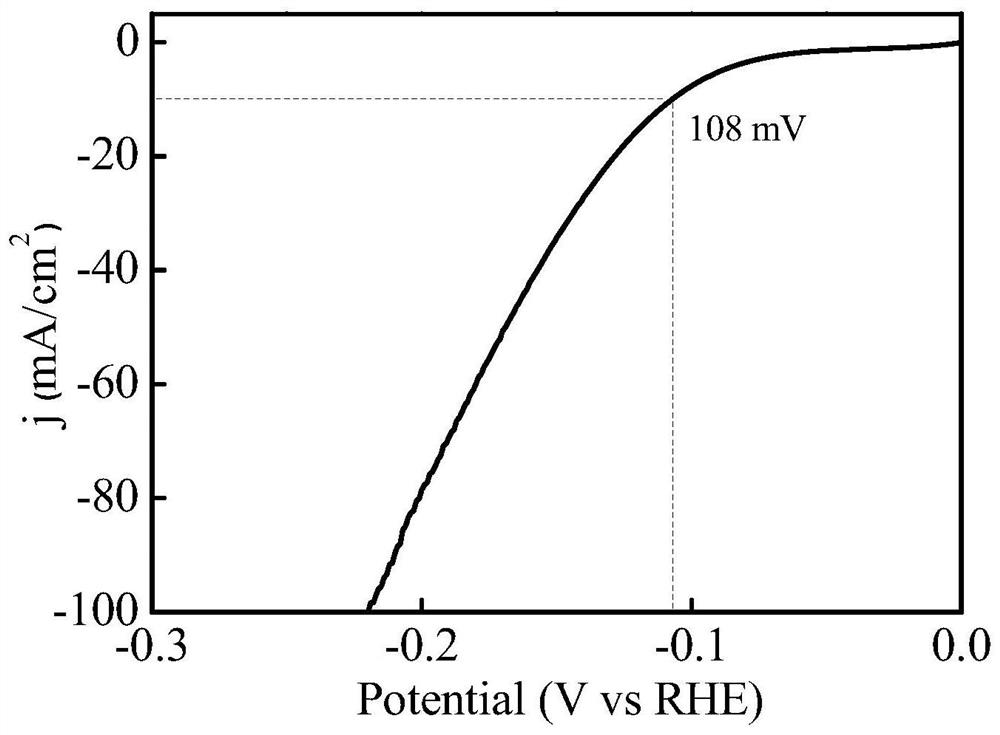

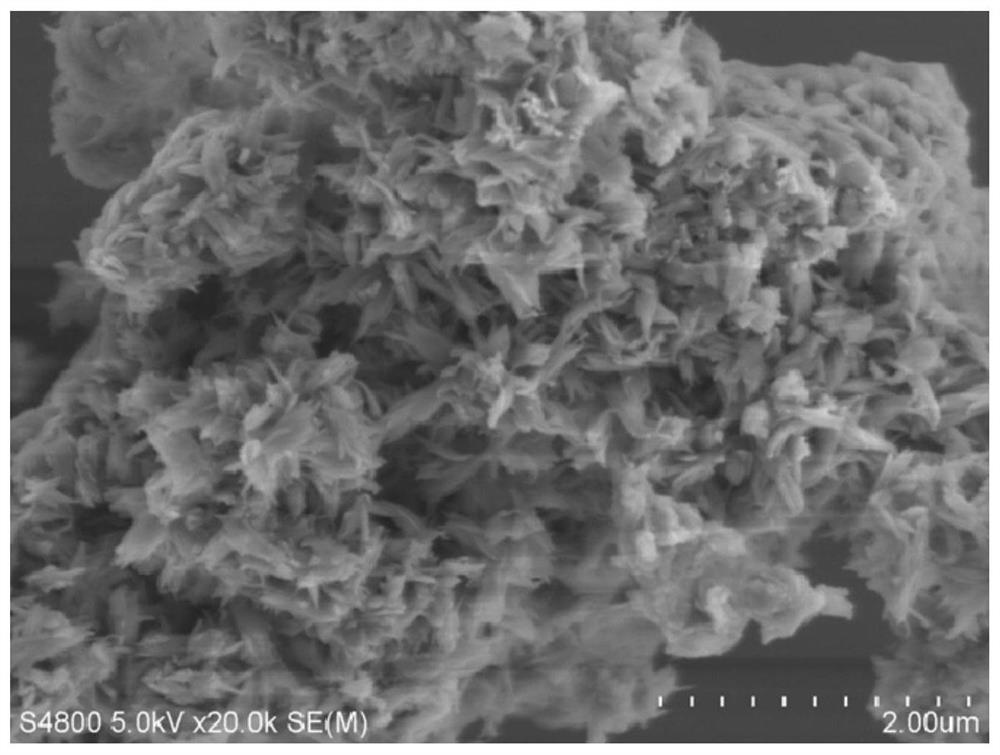

A technology of tungsten oxycarbide and composite materials, which is applied in the field of electrochemistry, can solve the problems that it is difficult to obtain high-efficiency, durable, and low-cost tungsten nitride composite materials, it is difficult to improve the catalytic efficiency of electrolytic water, and the synthesis temperature of tungsten nitride is high, so as to achieve improvement. Effects of cycle stability, uniform crystal structure and morphology, high purity and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A lily-shaped WN / W of the present invention 2 (C, O) the preparation method of composite material, comprises the steps:

[0028] Step 1, first mix pyrrole and absolute ethanol evenly, wherein the volume ratio of pyrrole and absolute ethanol is 1: (40-60), to obtain solution A;

[0029] Step 2, add a certain amount of tungsten source to a certain amount of ultrapure water to obtain solution B, the tungsten source is tungsten phosphate, the mass is 1.2-2g, and the volume of ultrapure water is 80-100mL;

[0030] Step 3: After mixing solution A and solution B at a volume ratio of 1:4, stir for 12-18 hours, induce pyrrole polymerization by tungsten phosphate to form polypyrrole PPy, and dry the precipitate after centrifugation at a drying temperature of 60-80 ℃, the collected product was labeled as PPy-PW 12 ; Since the molecular formula of tungsten phosphate is H 3 o 40 PW 12 .xH 2 O, here abbreviated as PW 12 ;

[0031] Step 4, put the collected samples into a porc...

Embodiment 1

[0035] (1) First mix pyrrole and absolute ethanol evenly, wherein the volume ratio of pyrrole and absolute ethanol is 1:40 to obtain solution A;

[0036] (2) Add 1.2g of tungsten phosphate into 80mL of ultrapure water to obtain solution B;

[0037] (3) After mixing 20mL of solution A and solution B, stir for 12h, after centrifugation, dry in a vacuum oven at 60°C, collect the obtained product and mark it as PPy-PW 12 ;

[0038] (4) Put the collected samples into a porcelain boat and place them in a high-temperature tube furnace, vacuumize, fill with argon, and repeat three times to remove the air in the tube. Min heat up to 800°C for nitridation for 2 hours, and take out the porcelain boat when it cools down to room temperature;

[0039] (5) Pour the sample in the porcelain boat into a mortar and grind it into a non-grainy powder to obtain lily-like WN / W 2 (C,O).

Embodiment 2

[0041](1) First mix pyrrole and absolute ethanol evenly, wherein the volume ratio of pyrrole and absolute ethanol is 1:50 to obtain solution A;

[0042] (2) Add 1.4g of tungsten phosphate to 90mL of ultrapure water to obtain solution B;

[0043] (3) After mixing 22.5mL of solution A and solution B, stir for 14h, after centrifugation, dry in a vacuum oven at 70°C, collect the obtained product and mark it as PPy-PW 12 ;

[0044] (4) Put the collected samples into a porcelain boat and place them in a high-temperature tube furnace, vacuumize, fill with argon, and repeat three times to remove the air in the tube. Min heat up to 900°C for nitriding for 3 hours, and take out the porcelain boat when it cools down to room temperature;

[0045] (5) Pour the sample in the porcelain boat into a mortar and grind it into a non-grainy powder to obtain lily-like WN / W 2 (C,O).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com