Wind-resistant metal roof structure and construction method thereof

A metal roofing and construction method technology, applied in the direction of roofing, roof covering, roofing using tile/slate tile, etc., can solve the problems of high requirements such as construction technology, material certification, quality control, detail node deepening, etc., to shorten the construction construction period, reduce the accuracy of installation and coordination, and cover the complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

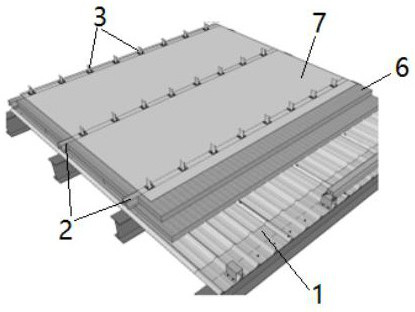

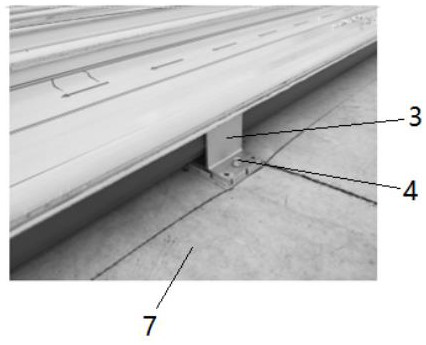

[0061] The present invention provides a wind-resistant metal roof structure, such as image 3 , Figure 4 As shown, it includes a metal roof panel and an aluminum alloy support 3, the metal roof panel is installed on the upper part of the aluminum alloy support 3, and the aluminum alloy support 3 is slidingly connected with the lining purlin 2 through a connecting mechanism 4, and the connection The mechanism 4 includes a first sliding gasket 41, a second sliding gasket 45, a compression spring 42, a connecting nut 43 and a connecting bolt 44 matched with the connecting nut 43. T-shaped hole 21, the lower part of the aluminum alloy support 3 is slidingly connected with the purlin 2 through the connecting bolt 44 and the connecting nut 43, and a first sliding gasket is installed between the lining purlin 2 and the aluminum alloy support 3 41, the lower part of the aluminum alloy support 3 is provided with a square groove 31, the width of the square groove 31 is consistent with...

Embodiment 2

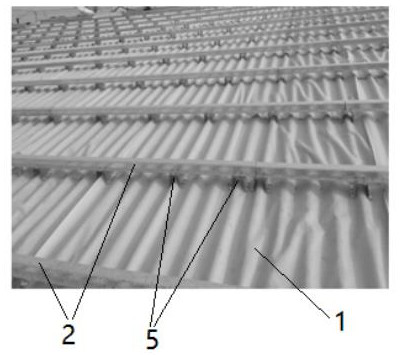

[0080] like figure 1 As shown, on the basis of Example 1, the bottom plate 1 in step S1 is made of a 0.6 mm thick YX15-225-900 gray color steel press-shaped punching bottom plate 1, and the punching rate is 20% to 23%. The bottom plate 1 is processed on site in advance, and fixed on the side supporting plates of the main purlins and secondary purlins with self-tapping screws. The self-tapping screws are installed on each trough of the bottom plate 1. It needs to be installed within the scope of the purlin, and the distance from the edge of the purlin is not less than 18mm. In addition, according to the requirements of FM, the locking nails need to use Biaodi special locking nails, the models are as follows, the horizontal spacing of the locking nails is 820mm, the vertical spacing is 600mm, and the locking nails at the lap joint of the bottom plate 1 should be encrypted to 450mm. When fixing the deck board on the I-beam purlin with conventional engineering self-tapping screw...

Embodiment 3

[0082] like figure 2 As shown, on the basis of Example 1, in step S2, the middle area adopts 2mm thick 25*70*70*70*25 galvanized purlins with a spacing of 1200mm, and the side area adopts 2mm thick 25*70*70*70*25 The galvanized purlins have a spacing of 900mm, and the corner area adopts 2mm thick 25*70*70*70*25 galvanized purlins with a spacing of 450mm. The spacing of the supports 5 is 1230mm, and the spacing of some areas can be Adjust as needed, the principle is no more than 1230mm, use 1070000 self-tapping screws for the connection between the support 5 and the main purlin, the quantity is according to the requirements of the node diagram, the number of self-tapping screws at each place is 4, the installation position of the self-tapping screws should be in the main purlin within the range of purlins, and the web that needs to avoid the center position; the specific method is to determine the edge and center position of the main purlin by setting out the line, and the ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com