An integrated filling-sand unloading device and experimental method for an oil flooding sand pipe model

An experimental method and a sand tube technology are applied in the field of an integrated device for filling and unloading sand tube models for oil displacement, which can solve the problems of uneven compaction, poor repeatability of sand tube models, and high pressure of hydraulic devices, and improve production efficiency. , High practical value, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

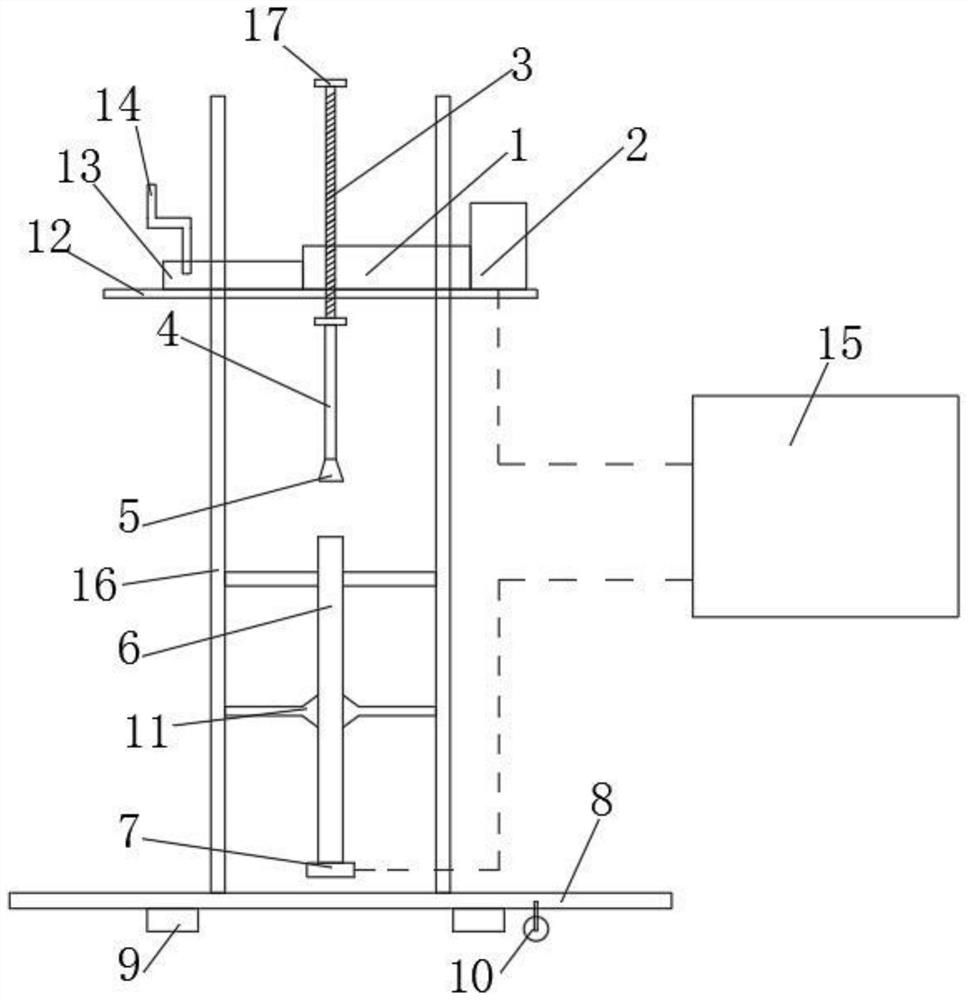

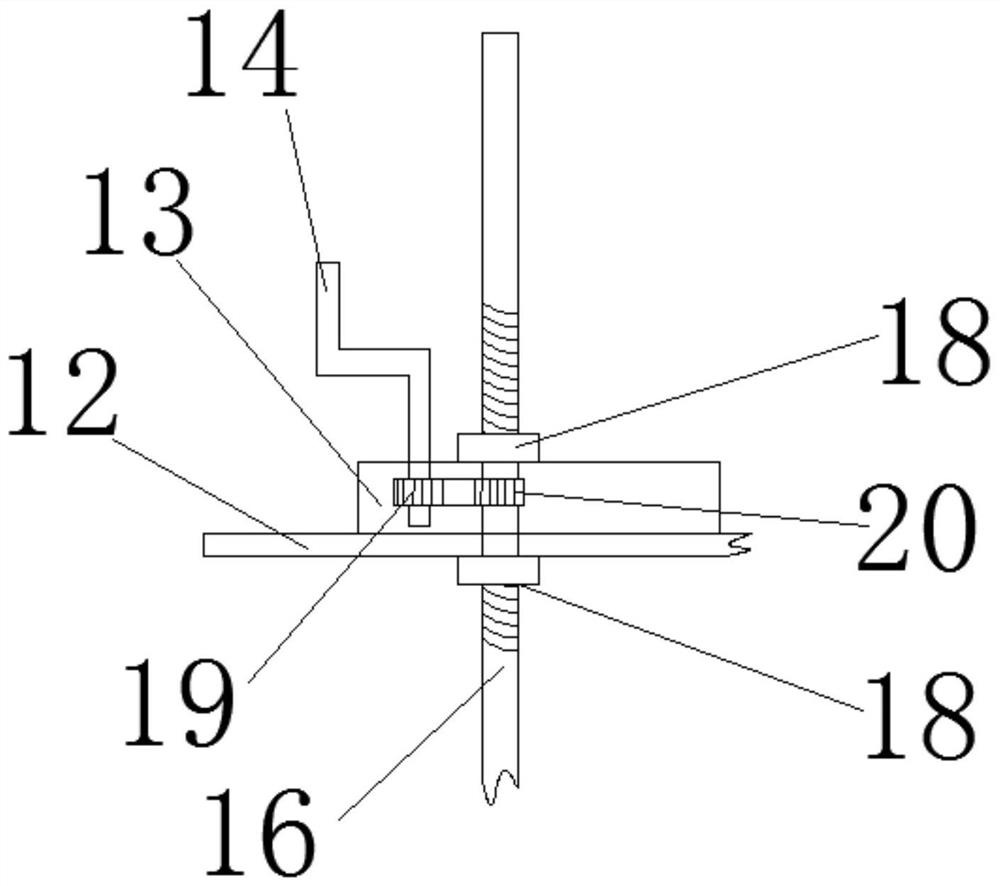

[0047] This embodiment provides a figure 1 The shown integrated sand filling-unloading device of the oil displacement sand pipe model includes a slideway guide rod 16 arranged on the support plate 8, and the slideway guide rod 16 is provided with a support girder 12, and the support girder 12 A gearbox 1 and a motor 2 are arranged on the top, the power output shaft of the motor 2 is connected to the gearbox 1, the output end of the gearbox 1 is connected to the upper end of the transmission screw 3, and the lower end of the transmission screw 3 passes through the After supporting the girder 12, it is connected with the push rod 4, the lower end of the push rod 4 is provided with a briquetting block 5, the briquetting block 5 is opposite to the sand pipe model 6, and the sand pipe model 6 is arranged above the support plate 8, The gearbox 1 is driven by the motor 2, the transmission screw 3 is driven by the gearbox 1, the transmission screw 3 pushes the push rod 4, the push rod...

Embodiment 2

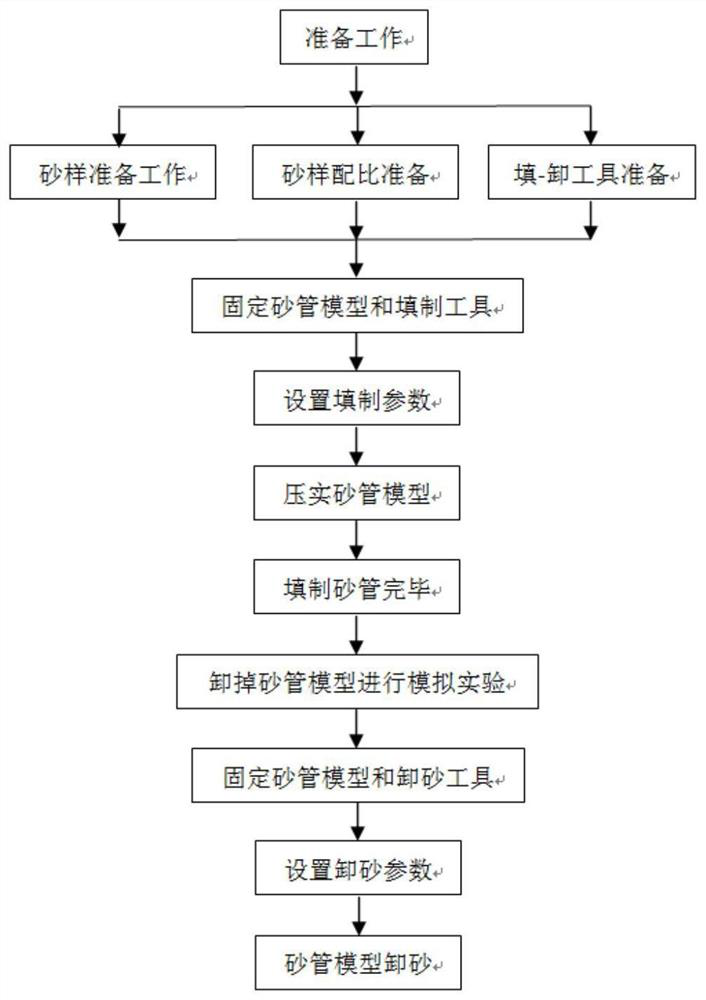

[0056] Such as figure 2 As shown, the experimental method of the filling-sand unloading integrated device of the described a kind of oil displacement sand pipe model, comprises the following steps:

[0057] Step 1. Prepare the sand samples required for the sand pipe model: After the natural core is washed with oil / salt and dried, it is rolled into a loose sample, and sand samples with different mesh numbers are selected by vibrating sieve or artificial quartz particles with different mesh numbers are selected. ;

[0058] Step 2. Determine the sand sample proportioning plan for the target reservoir permeability: According to the statistical data of the physical property parameters of the reservoir target reservoir and the particle size analysis results, specify the required sand samples, adjust the proportion of different sand samples, and establish the target reservoir permeability Sand sample proportioning scheme;

[0059] Step 3. Sand pipe model filling: fill the sand pip...

Embodiment 3

[0071] Artificial percussion method and the inventive method make sand pipe model contrast: long 100cm internal diameter 3.8cm sand pipe model; Sandstone particle diameter 120-200 order, 80-120 order, 40-80 order, 26-40 order, 16-26 Mesh and 1-2mm, 2-4mm; standard saline (NaCl: CaCl2: MgCl2.6H2O mass ratio is 7:0.6:0.4).

[0072] Manual filling steps: (1) According to the purpose and requirements of the experiment, select the corresponding sand sample proportioning scheme;

[0073] (2) According to the sand sample proportioning plan, weigh the required sand sample quality with a balance;

[0074] (3) Mix the sand samples taken by weighing evenly;

[0075] (4) Fix the sand pipe model on the bracket and fix it firmly;

[0076] (5) According to the filling plan, weigh 100g of uniformly mixed sand samples each time and put them into the sand tube model with a beaker;

[0077] (6) Put the compacting rod into the sand pipe model, and perform manual knocking 100 times;

[0078] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com