Molten iron transportation monitoring method, device and equipment and storage medium

A technology of molten iron and equipment, applied in image data processing, instruments, 3D modeling, etc., can solve problems such as hidden dangers of molten iron overflow, achieve the effects of reducing safety hazards, improving monitoring efficiency, and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

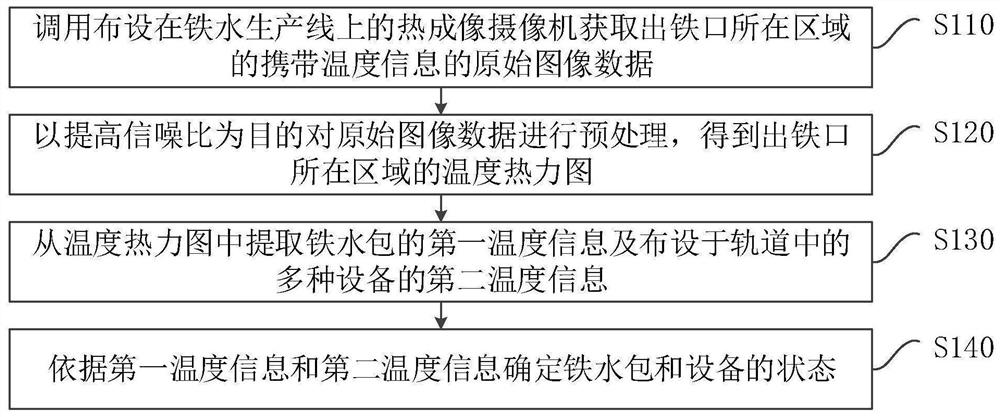

[0027] figure 1 It is a flow chart of a monitoring method for molten iron transportation provided by Embodiment 1 of the present invention. This embodiment is applicable to monitoring the area where the taphole of a steel plant is located, and the method can be implemented by a monitoring device for molten iron transportation , the monitoring device for molten iron transportation can be implemented by software and / or hardware, and can be configured in computer equipment, such as servers, workstations, industrial computers, personal computers, etc., the method specifically includes the following steps:

[0028] S110, calling the thermal imaging camera arranged on the molten iron production line to obtain original image data carrying temperature information of the area where the taphole is located.

[0029] Among them, the taphole is used to pour molten iron into the molten iron ladle transported on the track, and the track is arranged in the area where the taphole is located an...

Embodiment 2

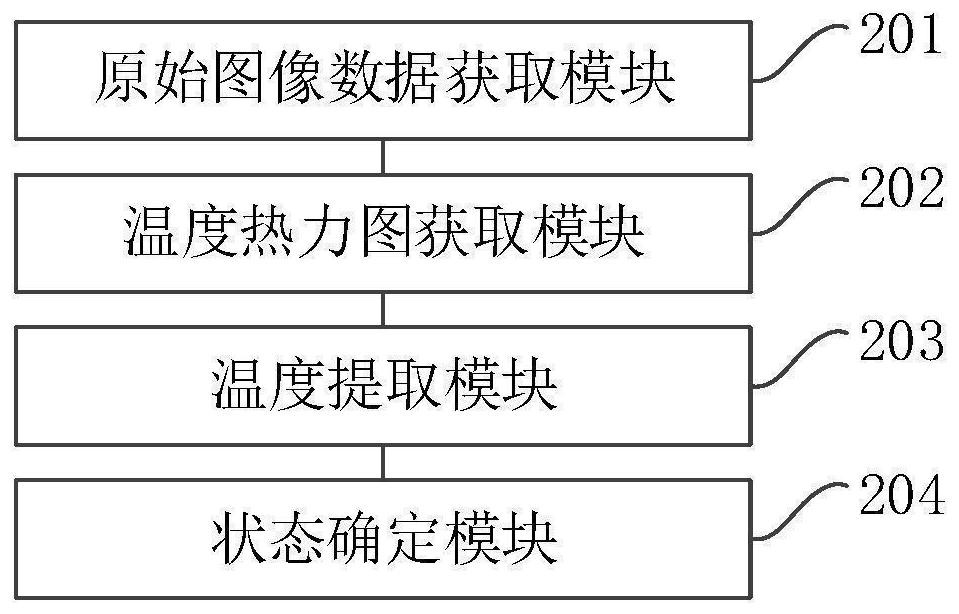

[0055] figure 2 It is a schematic structural diagram of a monitoring device for molten iron transportation provided in Embodiment 2 of the present invention. The device may specifically include the following modules:

[0056] The original image data acquisition module 201 is used to call the thermal imaging camera arranged on the molten iron production line to acquire the original image data carrying the temperature information of the area where the taphole is located, and the iron taphole is used to pour into the molten iron ladle transported on the track molten iron, the track is arranged in the area where the taphole is located and within the field of view of the thermal imaging camera;

[0057] A temperature thermodynamic map acquisition module 202, configured to preprocess the original image data for the purpose of improving the signal-to-noise ratio, and obtain a temperature thermodynamic map of the area where the taphole is located;

[0058] A temperature extraction m...

Embodiment 3

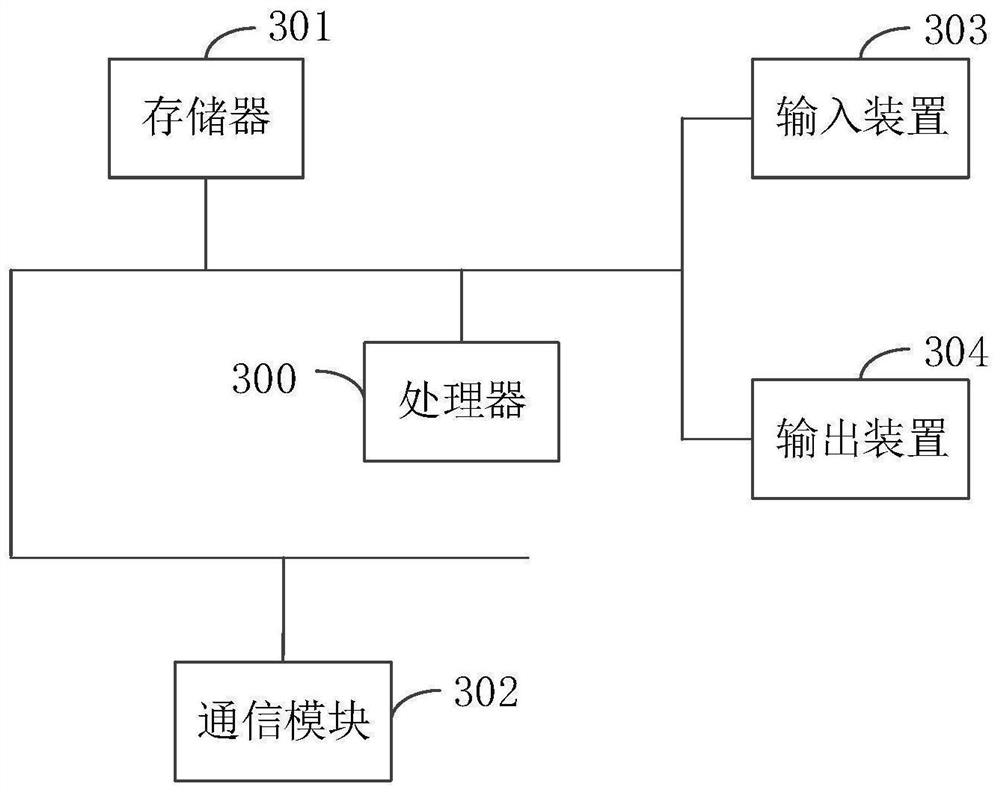

[0089] image 3 A schematic structural diagram of a computer device provided in Embodiment 3 of the present invention, such as image 3 As shown, the computer device includes a processor 300, a memory 301, a communication module 302, an input device 303 and an output device 304; the number of processors 300 in the computer device may be one or more, image 3 Take a processor 300 as an example; the processor 300, the memory 301, the communication module 302, the input device 303 and the output device 304 in the computer equipment can be connected through a bus or other methods, image 3 Take connection via bus as an example.

[0090] Memory 301, as a computer-readable storage medium, can be used to store software programs, computer-executable programs and modules, such as modules corresponding to the monitoring method for molten iron transportation in the embodiment of the present invention (for example, such as figure 2 The raw image data acquisition module 201, the tempera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap