Directional heteroepitaxy method and silicon-based germanium tin alloy material

A heterogeneous epitaxy and crystal orientation technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as difficulties, achieve crystal quality advantages, and shorten the effect of complex growth cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

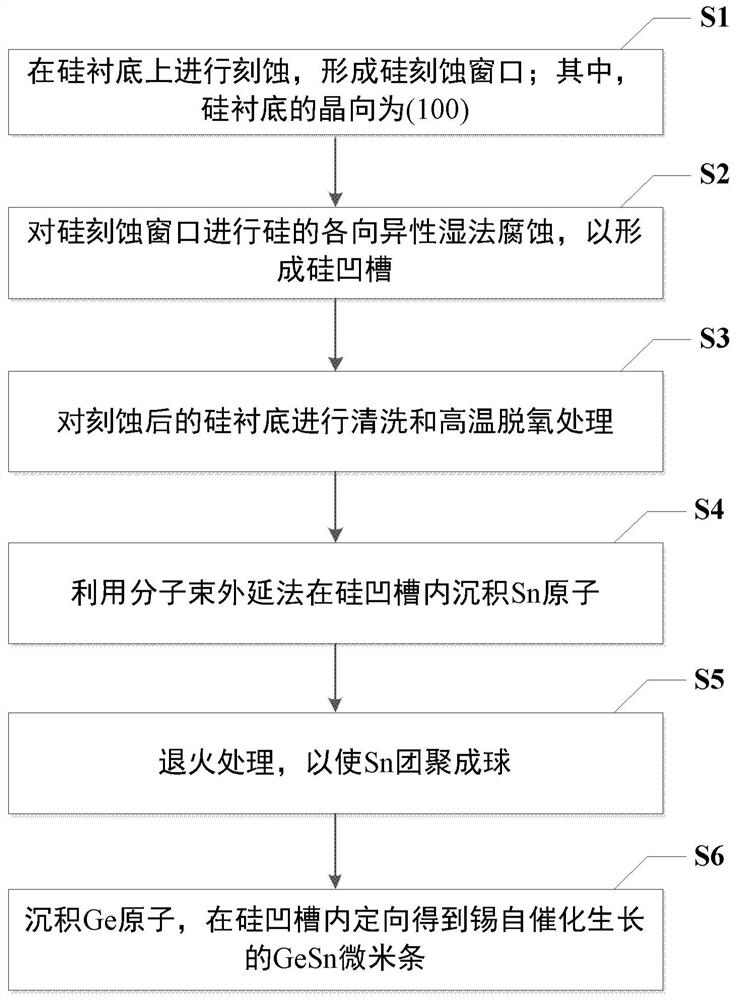

[0030] figure 1 A flow chart of a method for directional heteroepitaxy according to an embodiment of the present disclosure is schematically shown.

[0031] Such as figure 1 As shown, the present disclosure provides a method for directional heteroepitaxy, the method comprising:

[0032] In step S1, etching is performed on the silicon substrate to form a silicon etching window; wherein, the crystal orientation of the silicon substrate is (100).

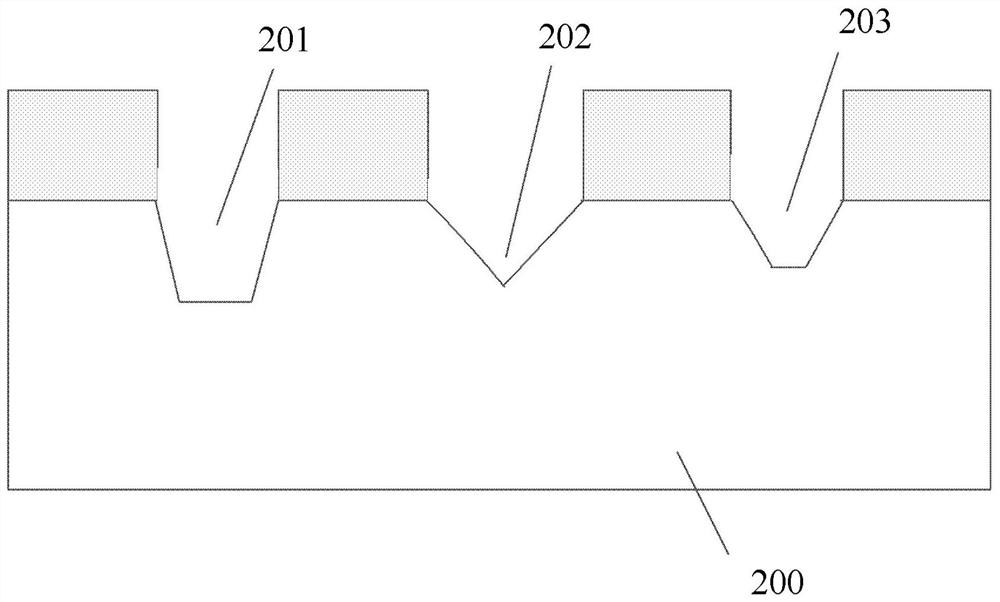

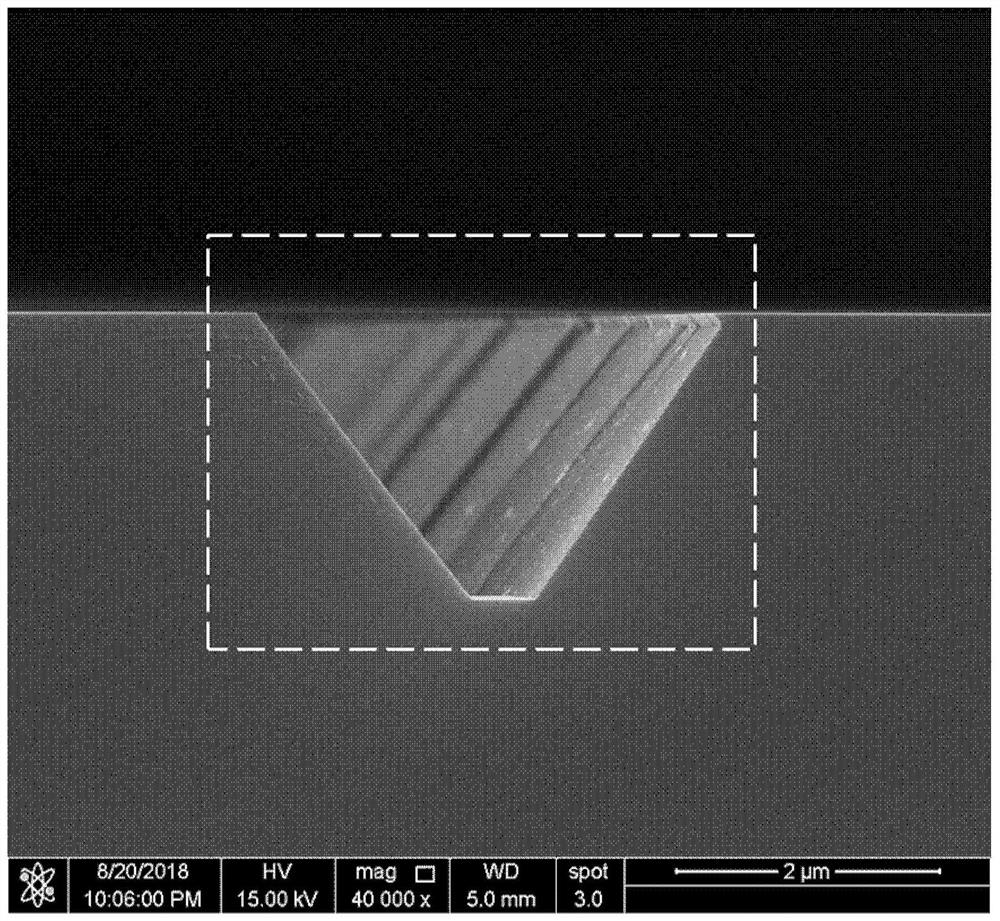

[0033] In step S2, anisotropic wet etching of silicon is performed on the silicon etching window to form silicon grooves.

[0034] In step S3, the etched silicon substrate is cleaned and deoxidized at high temperature.

[0035] In step S4, Sn atoms are deposited in the silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com