Coating diaphragm as well as preparation method and application thereof

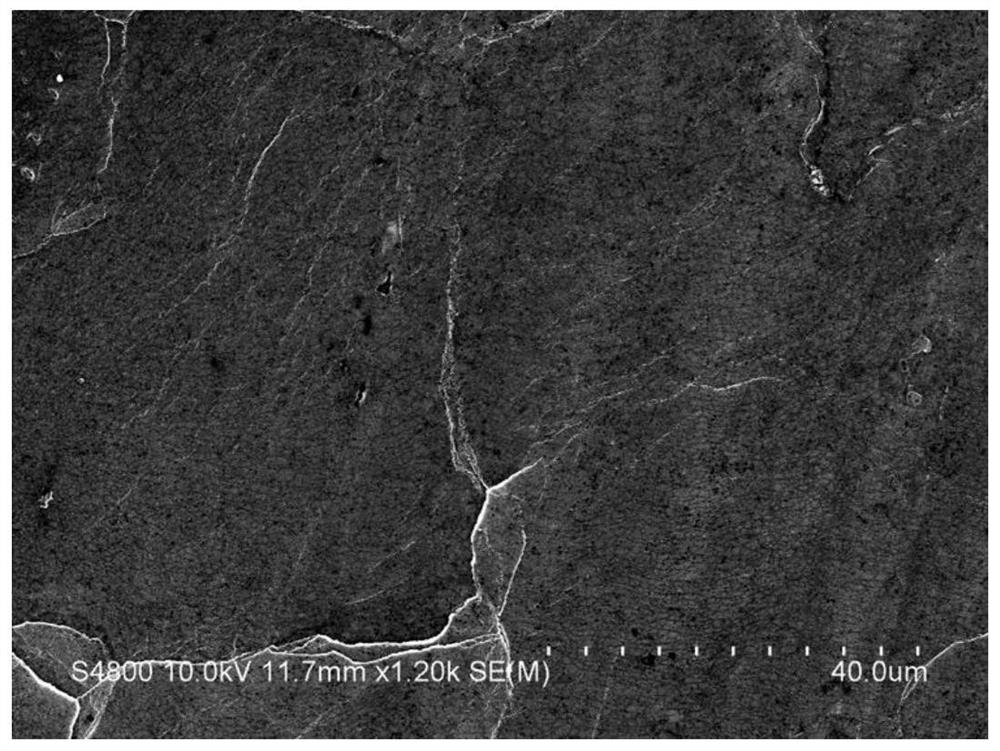

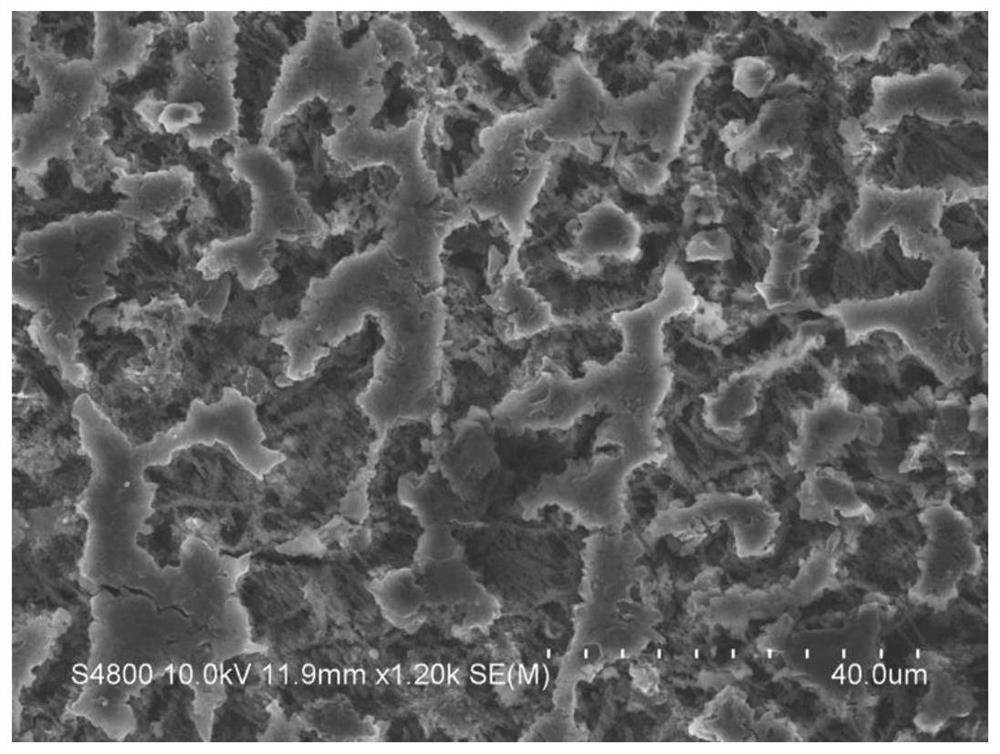

A membrane and coating technology, applied in the field of coating membrane and its preparation, can solve the problems of inability to completely suppress dendrites, and achieve the effects of component and content optimization, high flatness, and no dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

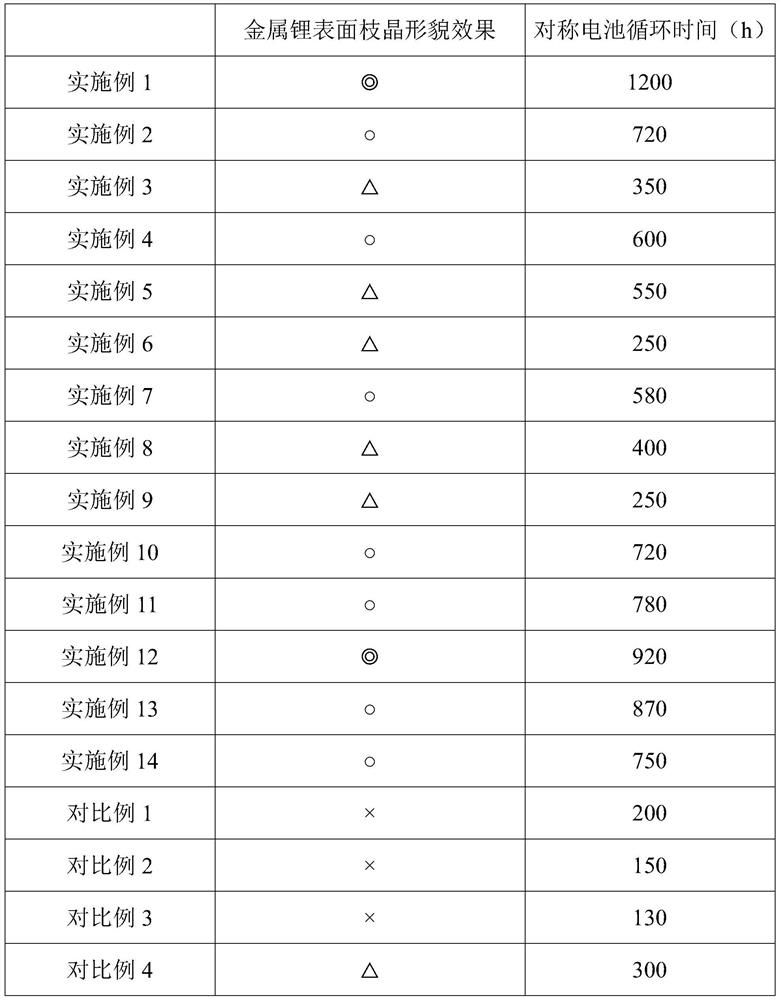

Examples

preparation example 1

[0066] A kind of exfoliated hydrotalcite containing anion-fixed structure, the preparation method is as follows:

[0067] (1) Commercially purchased magnesium-aluminum hydrotalcite (Mg-Al LDH) was calcined at 450°C for 5 hours under an argon atmosphere to obtain a double-layer oxide free of carbonate ions and water; the above-mentioned double-layer oxide was dispersed In 15 mL ethanol / H containing 0.3 g lithium bistrifluoromethanesulfonimide (LiTFSI) 2 O mixed solution (12mL ethanol, 3mL H 2 O) was stirred at 70° C. for 12 h to obtain a pre-layered Mg-Al LDH;

[0068] (2) The pre-layered Mg-Al LDH obtained in step (1) was centrifuged and calcined at 250 °C for 3 h under an argon atmosphere to remove H in the intermediate layer 2 O, obtain intermediate product;

[0069] (3) Disperse 1.15 g of the intermediate product obtained in step (2) in 30 mL of N,N-dimethylformamide (DMF) containing 2.3 g of LiTFSI, and perform ultrasonic treatment and stirring for a total of 12 hours t...

preparation example 2

[0071] A kind of exfoliated hydrotalcite containing anion-fixed structure, its difference with Preparation Example 1 is only that LiTFSI in step (2) and step (3) is used lithium hexafluorophosphate (LiPF 6) replacement, the exfoliated Mg-Al LDH with anion-fixed structure was obtained.

preparation example 3-6

[0073] A kind of exfoliated hydrotalcite containing anion-fixed structure, its difference from Preparation Example 1 is that the quality of the intermediate product in step (3) is respectively 2.8g, 2.3g, 0.6g, 0.4g, to obtain anion-fixed structure exfoliated Mg-Al LDH.

[0074] The materials used in the following examples of the present invention and comparative examples include:

[0075] Diaphragm substrate: single-layer polypropylene diaphragm, Celgard 2400;

[0076] Binder: Polyvinylidene Fluoride (PVDF), Source Leaf, S25907.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com