Crankshaft forge piece turnover device of die forging press

A turning device and press technology, which is applied to forging/pressing/hammer devices, forging/pressing/hammering machinery, engine components, etc., can solve the problems of poor consistency of turning direction, low safety factor, and affecting the shaping of forgings, etc., to achieve Effects of improving quality and dimensional accuracy, improving operational safety, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

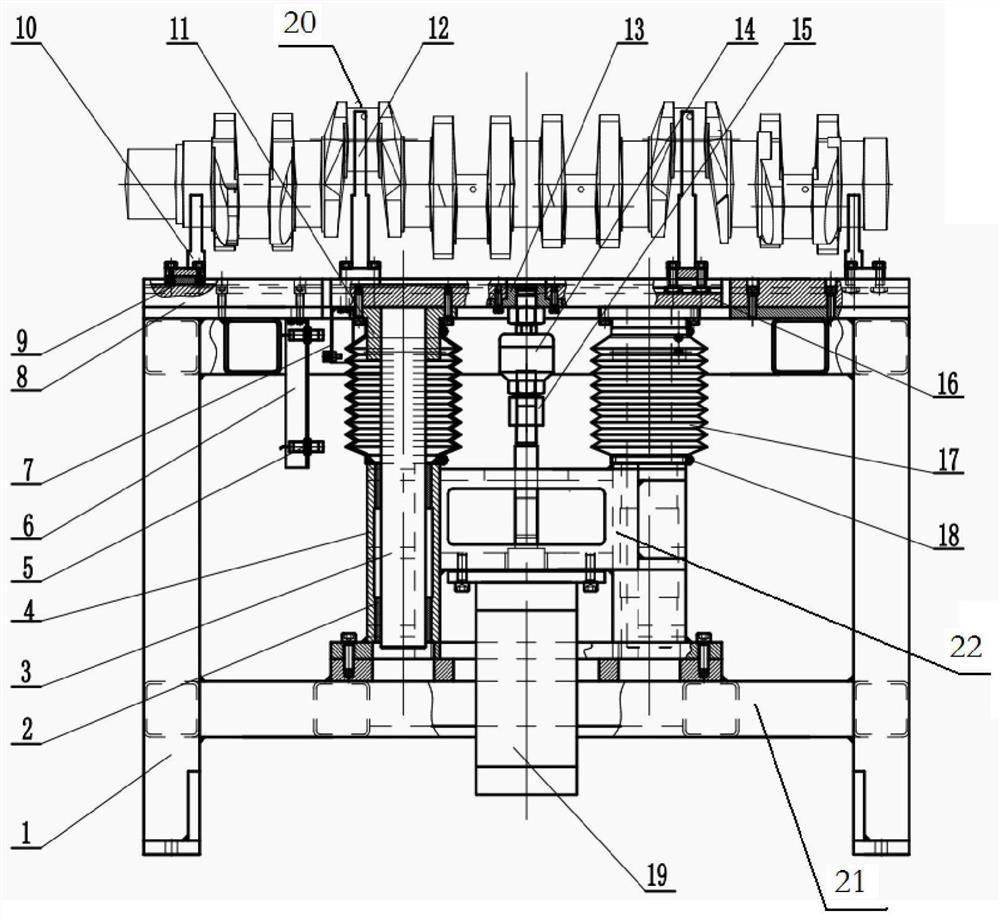

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, 1 present invention comprises frame 1,

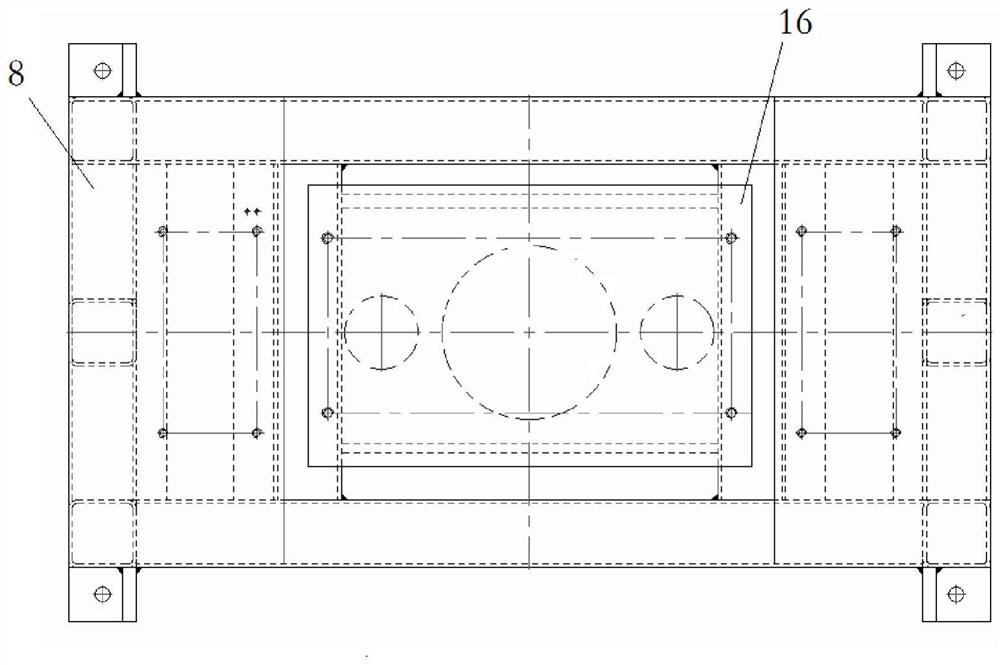

[0013] A slideway one is set on the top plate 8 of the frame 1, and a connecting seat 9 is arranged on the slideway one, and a V-shaped support block 10 is fixedly connected on the connecting seat 9; figure 1 The dovetail groove in the left and right directions, the lower end of the connecting seat 9 is provided with a trapezoidal convex part, the trapezoidal convex part is inserted in the dovetail groove, and fixed with bolts, and then the position of the connecting seat can be adjusted according to the length of the crankshaft;

[0014] Cylinder 19 is arranged on the bottom plate 21, and the piston rod of the cylinder is connected with top plate 16; Described upper plate 8 is rectangular frame type, and the length of left and right sides is bigger, and slideway 1 is arranged above; Top plate 16 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com