Automatic dust removal device and dust removal method for tipping of intermediate tank

A technology of automatic dust removal and vacuum hood, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of large volume, unguaranteed suction effect, complex structure, etc., to avoid on-site operation and facilitate The use of dust removal and daily maintenance, the effect of improving the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

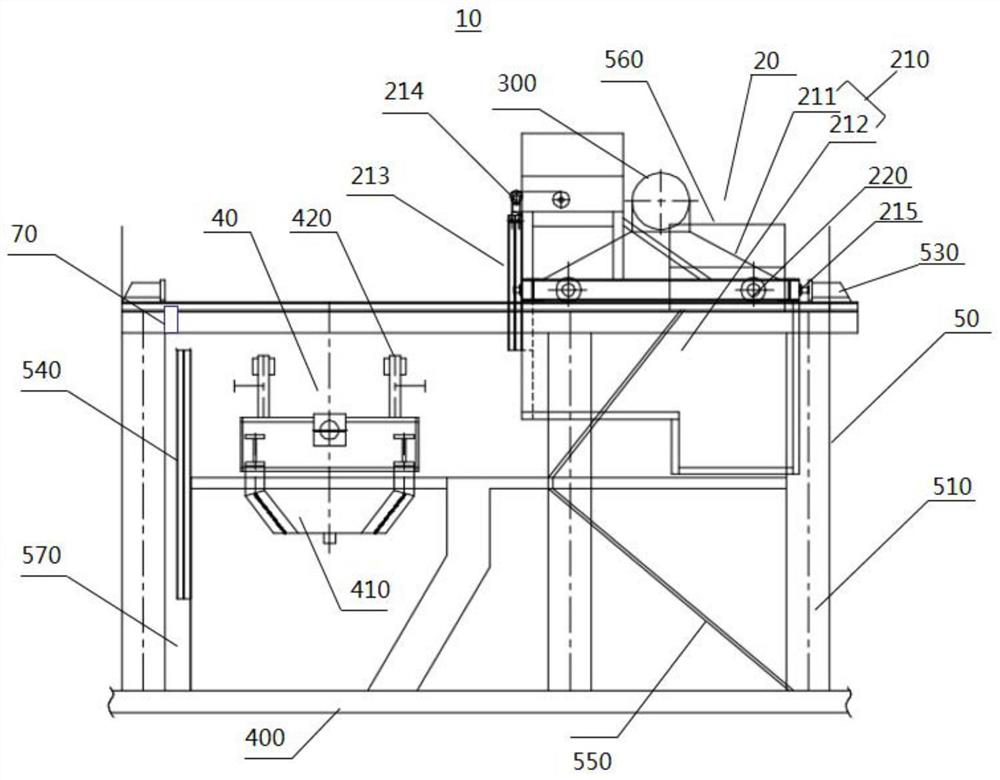

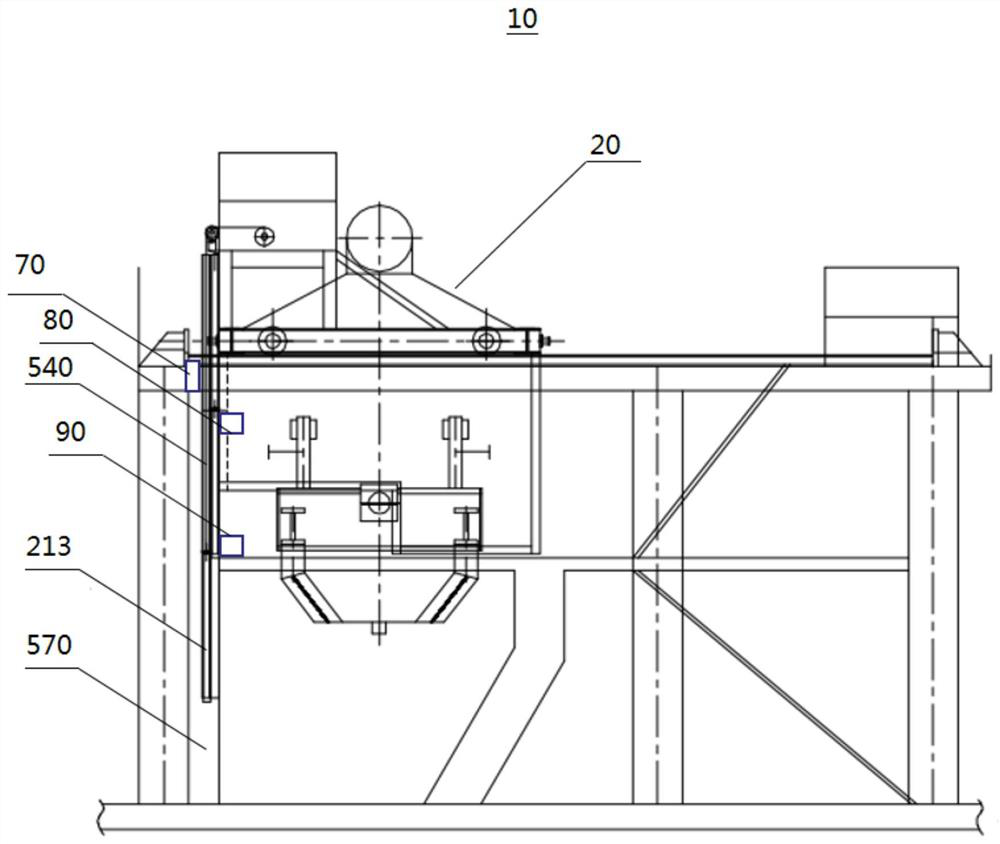

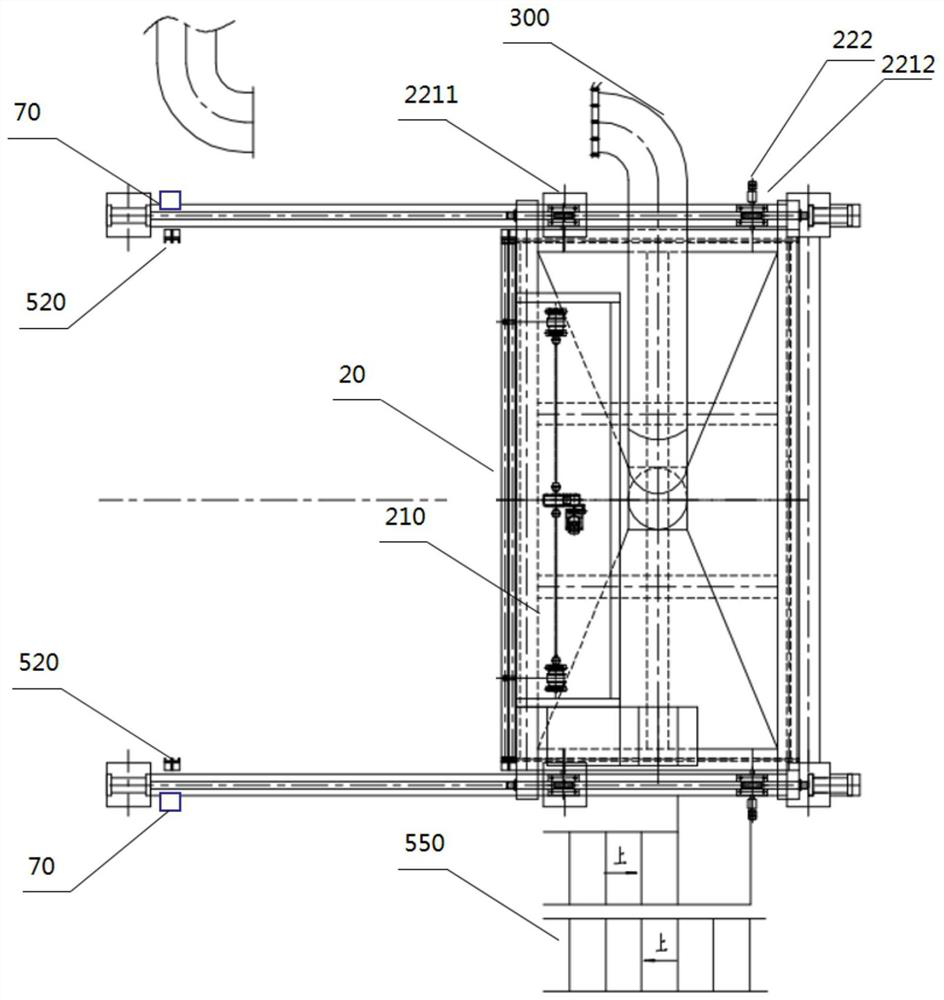

[0051] see figure 1 , the embodiment of the present application provides a tundish tank tipping automatic dust removal device 10, including: a mobile dust collection hood 20, a dry fog dust suppression assembly 30 ( figure 1 Not shown in), the tundish turning device 40, the vehicle frame 50. Among them, the mobile dust collection hood 20 is supported on the vehicle frame 50, and the vehicle frame 50 is installed around the tundish overturning device 40. When the tundish is overturned and dust removal is required, the mobile dust collection hood 20 can be moved from the standby position along the The vehicle frame 50 advances and moves to the working position to perform dust removal work on the turning area. The vehicle frame 50 is installed on the tipping table 400 .

[0052] Wherein, the mobile dust collection hood 20 includes a dust collection hood 210 and a moving assembly 220, and the moving assembly 220 is installed on both sides of the dust collection hood 210; 211 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com