Online MDO manufacturing method of bottled beverage self-adhesive label film

A self-adhesive label and beverage technology, applied in the field of beverage packaging, can solve the problems of high equipment cost, high production cost, and poor fit, and achieve reduced labor costs, increased tensile strength, and good one-way tearability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

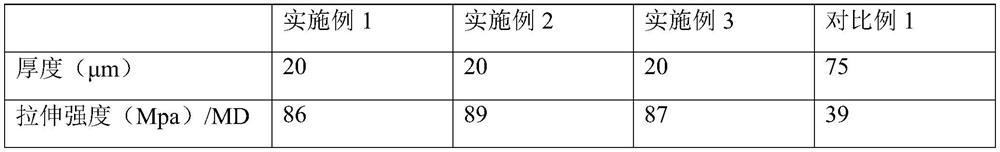

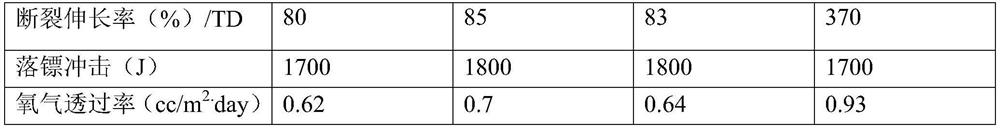

Embodiment 1

[0033] A bottled beverage self-adhesive label film with a thickness of 20 μm, which includes a printing surface layer, a barrier layer and an adhesive layer from top to bottom. The printing surface layer is divided into an upper surface and a lower surface, and the printing surface layer is made of BOPP material. The layer is made of EVOH, and the adhesive layer is a mixture of starch, casein and synthetic polymers.

[0034] Among them, the thickness of the printed surface layer accounts for 30% of the total thickness of the self-adhesive label film, and the thickness of the barrier layer accounts for 40% of the total thickness of the self-adhesive label film.

[0035] Among them, the BOPP material is BOPP degradable film produced by Foshan Fengbei Film New Material Co., Ltd., and the EVOH material is purchased from Japan Kuraray Company.

[0036] The preparation method of the above-mentioned bottled beverage self-adhesive label film comprises the following steps:

[0037] S1...

Embodiment 2

[0043] A bottled beverage self-adhesive label film with a thickness of 20 μm, including a printing surface layer, a barrier layer and an adhesive layer from top to bottom, the printing surface layer is divided into an upper surface and a lower surface, wherein the printing surface layer is made of BOPP material , the barrier layer is made of PVDC material, and the adhesive layer is a mixture of starch, casein and synthetic polymers.

[0044] Among them, the thickness of the printed surface layer accounts for 50% of the total thickness of the self-adhesive label film, and the thickness of the barrier layer accounts for 35% of the total thickness of the self-adhesive label film.

[0045] Among them, the BOPP material is the BOPP degradable film produced by Foshan Fengbei Film New Material Co., Ltd., and the PVDC is purchased from Xingtai Weite Plastic Industry Co., Ltd.

[0046] The preparation method of the above-mentioned bottled beverage self-adhesive label film comprises the...

Embodiment 3

[0053] A bottled beverage self-adhesive label film with a thickness of 20 μm, which includes a printing surface layer, a barrier layer and an adhesive layer from top to bottom. The printing surface layer is divided into an upper surface and a lower surface, and the printing surface layer is made of BOPP material. The layer is made of EVOH, and the adhesive layer is a mixture of starch, casein and synthetic polymers.

[0054] Among them, the thickness of the printed surface layer accounts for 30% of the total thickness of the self-adhesive label film, and the thickness of the barrier layer accounts for 40% of the total thickness of the self-adhesive label film.

[0055] Among them, the BOPP material is BOPP degradable film produced by Foshan Fengbei Film New Material Co., Ltd., and the EVOH material is purchased from Japan Kuraray Company.

[0056] The preparation method of the above-mentioned bottled beverage self-adhesive label film comprises the following steps:

[0057] S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corona value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com