A kind of instant superfine solid massive carbon black and its preparation method and application

An instant, carbon black technology, applied in chemical instruments and methods, fiber types, fibrous fillers, etc., can solve the problems of carbon black dust pollution, harm to the health of operators, dispersion, etc., and achieve excellent antistatic properties and electrical conductivity. properties, excellent application performance, and the effect of solving the agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

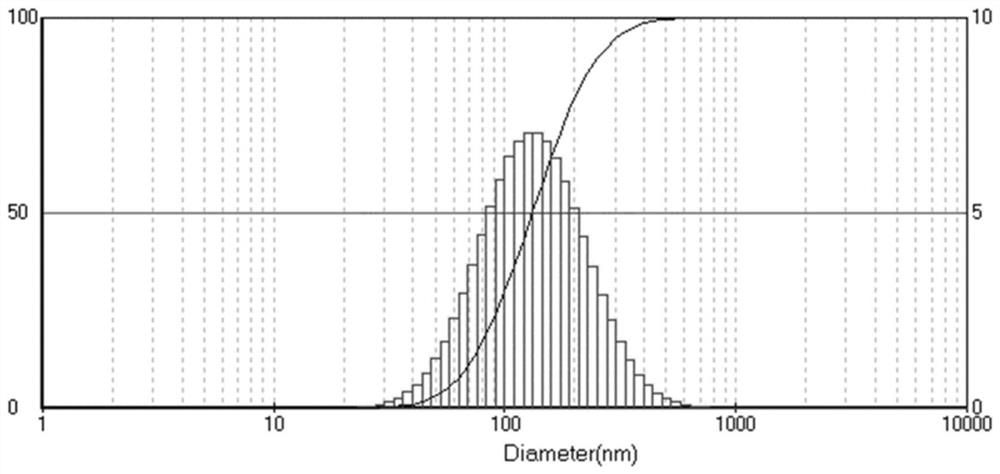

[0048] 1000 grams of carbon black 15F, 96 grams of dispersant MF, 97 grams of sodium lignosulfonate-N, 34 grams of octadecylamine polyoxyethylene ether (EO=15), 33 grams of Pingpingjia O15 (EO=15), 34 Pre-mix 6 grams of polyether polyol HSH-210, 6 grams of dispersant RQT-FS and 8700 grams of water to prepare a carbon black solution, with a total of 300 grams of additives. The carbon black solution was continuously ground for 2 hours in a zirconia ball mill to obtain a carbon black emulsion. The above-mentioned nano-carbon black emulsion is placed in a container and dried to obtain solid block carbon black.

Embodiment 2

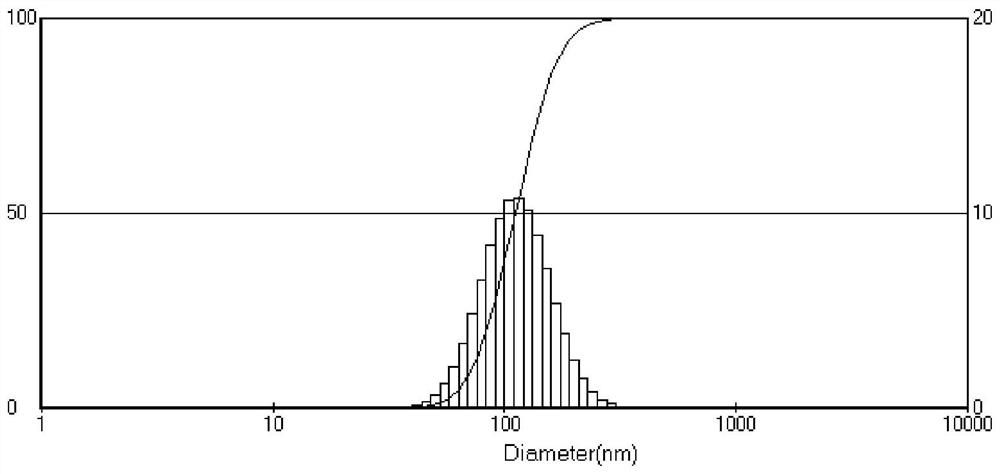

[0050] 1000 grams of carbon black F15, 82 grams of dispersant MF, 81 grams of sodium lignosulfonate-N, 41 grams of octadecylamine polyoxyethylene ether (EO=15), 41 grams of Pingpingjia O15 (EO=15), 41 The carbon black solution was prepared by pre-mixing 1 g polyether polyol HSH-210, 14 g dispersant RQT-FS and 8700 g water. The carbon black solution was continuously ground for 2.5 hours in a zirconia grinding device to obtain a carbon black emulsion. The above-mentioned nano-carbon black emulsion is placed in a container and dried to obtain solid block carbon black.

Embodiment 3

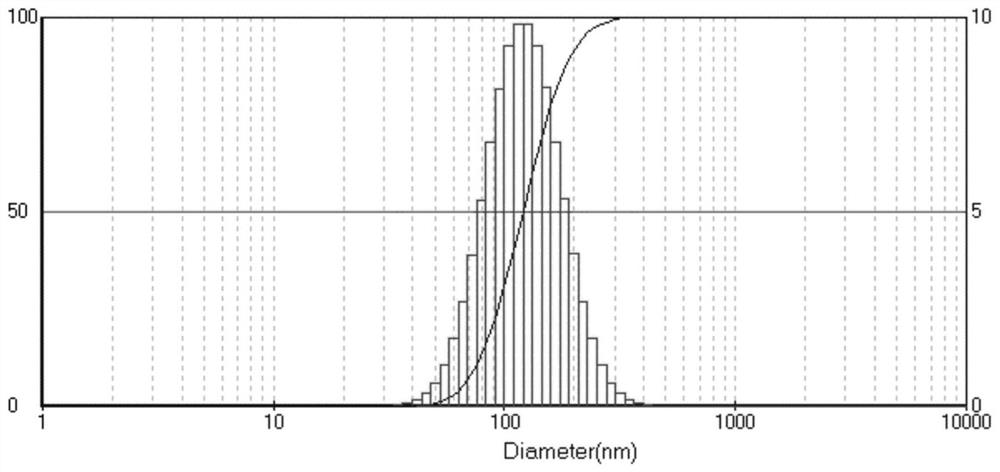

[0052] 2000 grams of carbon black F15, 157 grams of dispersant MF, 157 grams of sodium lignosulfonate-N, 50 grams of octadecylamine polyoxyethylene ether (EO=15), 45 grams of Pingpingjia O15 (EO=15), 78 The carbon black solution was prepared by pre-mixing 1 g of polyether polyol HSH-210, 13 g of dispersant RQT-FS and 7500 g of water. The carbon black solution was continuously ground for 2.5 hours in a zirconia grinding device to obtain a carbon black emulsion. The above-mentioned nano-carbon black emulsion is placed in a container and dried to obtain solid block carbon black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com