A kind of nanosheet layered carbon black emulsion and its preparation method and application

A technology of nanosheets and carbon black, applied in chemical instruments and methods, fibrous fillers, textiles and papermaking, etc., can solve the problems of uneven coating, complicated process, high cost, etc., solve the problem of agglomeration and improve antistatic Sexuality, the effect of excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

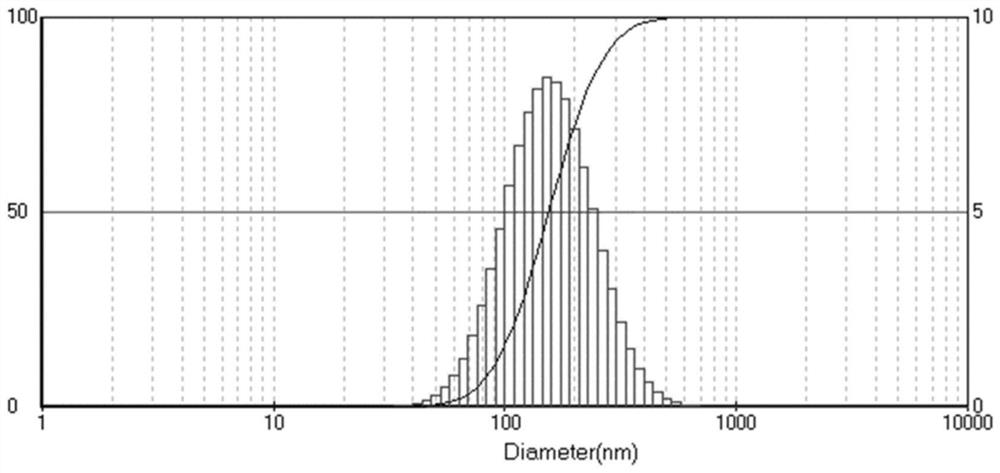

[0033] 2000 kg of carbon 15F, 168 g of dispersant MF, 200 grams of sodium plain sulfate-N, 55 grams of octadamine polyoxyethylene ether (EO = 15), 117 grams of flat plus O15 (EO = 15), 78 The polyether polyol HSH, 32 g of dispersant RQT-Fs and 7350 g of water were premixed, and the carbon black solution was obtained, and the abrasive was 650 grams. Carbon black solution was continuously ground in a zirconia abrasive apparatus for 3 hours to prepare a carbon black emulsion. The above-mentioned carbon black emulsion was placed in a container, and solid bulk carbon black A was dried.

Embodiment 2

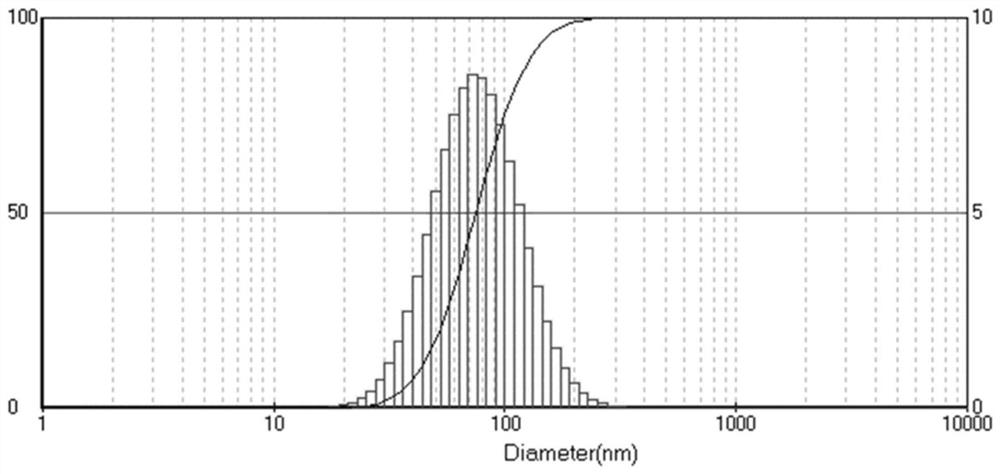

[0035] 3000 g of charging F15, 300 g of dispersant MF, 314 grams of wood sulfate-N, 100 grams of octadamine polyoxyethylene ether (EO = 20), 100 grams of flat plus O15 (EO = 30), 156 The polyether polyol HSH, 30 grams of dispersant RQT-FS and 6000 g of water were premixed, produced carbon black solution, and the abrasive was 1000 grams. Carbon black solution was continuously ground in a zirconia abrasive apparatus for 3 hours to prepare a carbon black emulsion. The above-mentioned carbon black emulsion was placed in a container, and the solid bulk carbon black B was dried.

[0036] Embodiment 4 of another inventive application (a speed-soluble ultra-fine solid bulk carbon black and preparation method and application thereof) is respectively submitted in the same day, respectively, and Example 5; The materials composition of 3 to Example 6 are as follows:

[0037]

[0038] In the table, the fourth column 4 to 9 is the detailed composition of the dispersant.

Embodiment 3

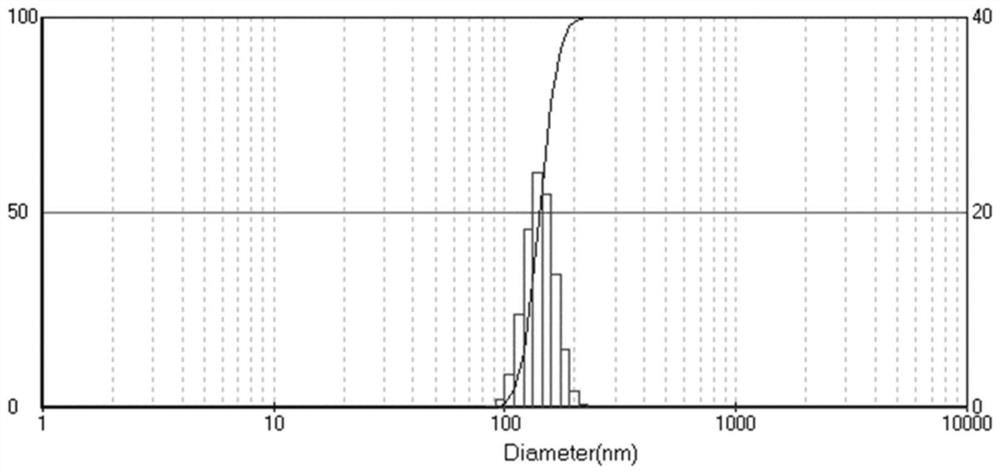

[0040] 500 grams of solid bulk carbon black A (Example 1), 10 grams of dispersant MF, 21 grams of sodium sulfonate N, 4 g of octade amine polyoxyethylene ether (EO = 15), 4 grams flat plus O15 (EO = 15), 8 grams of polyether polyol HSH, 3 g of dispersant RQT-Fs and 9450 g of water were premixed, and the carbon black solution was obtained. The carbon black solution was continuously ground in the zirconia abrasive apparatus for 2 hours, and the carbon black particle diameter was not higher than 100 nm of nanoculate black emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com