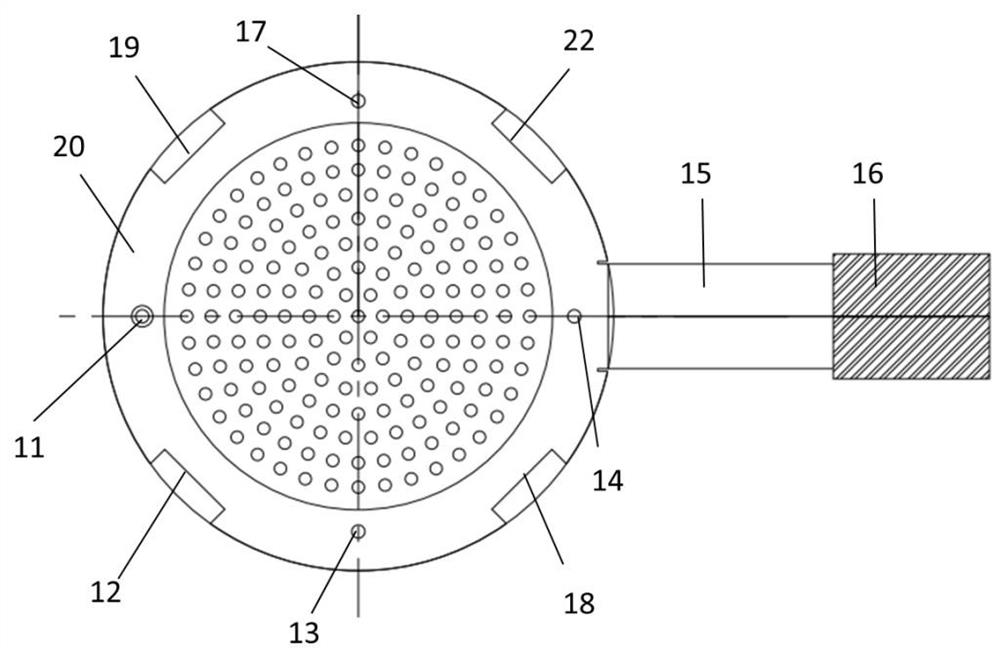

Novel semiconductor single crystal wafer dislocation density detection corrosion tool and method

A chip and tooling technology, which is applied in the corrosion field of silicon carbide wafers, can solve the problems that the corrosion safety and stability have not been significantly improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Segmental lipping preheating and cooling method

[0059] Using the lift rod according to the decrease in divisions and lifting, only the wafer clamp in the tool is used.

[0060] Specific steps are as follows:

[0061] Step 1: Analyze 1.5 kgKOH to the melt to melt, keep the molten liquid temperature of about 505 ° C;

[0062] Step 2: The wafer clamp is mounted to the pullement rod, and the low heat is lowered at a height of the near liquid surface;

[0063] Step 3: The lower clamp is to enter the liquid surface at the bottom, and the wafer remains above the liquid surface, preheating for 2min;

[0064] Step 4: Continue drop to the wafer to immerse corrosion fluid, corrode 4.5 min;

[0065] Step 5: Corrosion is completed, lift the clamp to the distance liquid surface 2 cm, maintained 3.5 min;

[0066] Step 6: Rapidity to 10cm from the liquid level, cool 2min;

[0067] Step 7: Horizontal moving fixture to the cooling station, cool to 147 ° C;

[0068] Step 8: Place the fixtur...

Embodiment 2

[0072] Continuous liping and cooling method

[0073] Corrosion and improvement in the stepper motor, only the wafer clamp in the tooling.

[0074] Specific steps are as follows:

[0075] Step 1: Analyze 1.5 kgkoH to analyze the purifier to melt, keep the molten liquid temperature of about 511 ° C;

[0076] Step 2: The wafer clamp is mounted to the pull rod, and the low heat is lowered at a height of the near liquid surface;

[0077] Step 3: Control the stepper motor speed of 2.5mm / s, a falling fixture, and a preheating is 2min;

[0078] Step 4: Continuously drop the wafer and immersed in the corrosive liquid, corroded 4 min;

[0079] Step 5: Corrosion is completed, which increases the jig to 15cm from the liquid level at 3 mm / s.

[0080] Step 6: Horizontal moving fixture to the cooling station, cool to 152 ° C;

[0081] Step 7: Place the fixture and the wafer in a 90 ° C water bath and soak for 3 min.

[0082] Step 8: Take out the wafer, remove the deionized water, dry, dry, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com