Physical explosive cleaning device and method for solid rocket engine

A rocket engine and solid rocket technology, applied in the direction of rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as propellant failure, damage to the body, combustion, explosion, etc., achieve humidification and cooling, avoid environmental protection problems, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

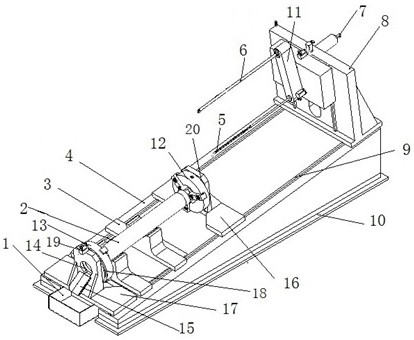

[0025] In order to overcome the problems of low production efficiency, potential safety hazards in the existing cutting tool cleaning operation, and large pollution of water jet cutting cleaning chemicals, the present invention provides such figure 1 A solid rocket motor physical medicine cleaning device is shown. The invention cuts the propellant to form an annular groove array through the revolution of the engine + the rotation of the cutter, and cuts the propellant to form strips of medicine by cutting the propellant through the revolution of the engine and the linear motion of the cutter; the whole cleaning The medicine process realizes the low-speed and high-efficiency cleaning of the propellant, and the invention uses a physical tool to clean the medicine. Compared with the high-pressure water cutting method, it is green and environmentally friendly, and the cut propellant can be reused to avoid environmental protection problems caused by destruction.

[0026] Such as fi...

Embodiment 2

[0029]On the basis of Embodiment 1, in this embodiment, preferably, the upper part of the second slideway seat 17 of the rocket motor is connected to the second fixed chuck 13 of the rocket motor, and a pill discharge hole 14 is provided. A drug block discharge tank 15 is provided below the block discharge hole 14 , and a drug block collection box 1 is provided at the bottom of the drug block discharge tank 15 .

[0030] During actual use, the cut propellant is recovered through the pill collection box 1 for secondary use.

Embodiment 3

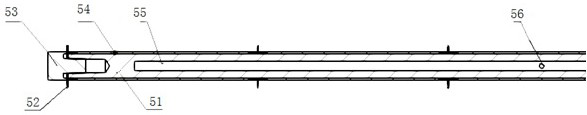

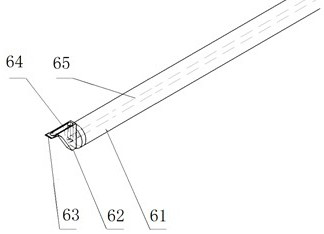

[0032] On the basis of embodiment 1, in this embodiment, as figure 2 As shown, preferably, the ring cutter 5 includes a ring cutter bar 51, a spacer 54 installed on the outer surface of the ring cutter bar 51, and the outer side of the spacer 54 is fixed with equidistant parallel distribution. A plurality of ring cutting blades 52, the spacer sleeve 54 is tightly connected with the ring cutter bar 51 by a compression nut, the ring cutter bar 51 is hollow inside, and is provided with a ring cutter bar cold air passage 55 , the surface of the ring cutter bar 51 and the spacer sleeve 54 are distributed with a number of penetrating cold air holes 56 , and the cold air holes 56 communicate with the cold air channel 55 of the ring cutter bar.

[0033] During actual use, the outer side of the spacer 54 is fixed with a plurality of circumcision blades 52 equidistantly distributed in parallel, and the circumscribed blades 52 are equidistantly distributed in parallel, so that the prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com