Wind excitation vibration wear simulation test device for composite insulated cross arm

A technology of composite insulation and vibration excitation, applied in vibration testing, measuring devices, testing wear resistance, etc., can solve the problems of the complexity of breeze vibration, increased power loss of transmission lines, affecting people's lives and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

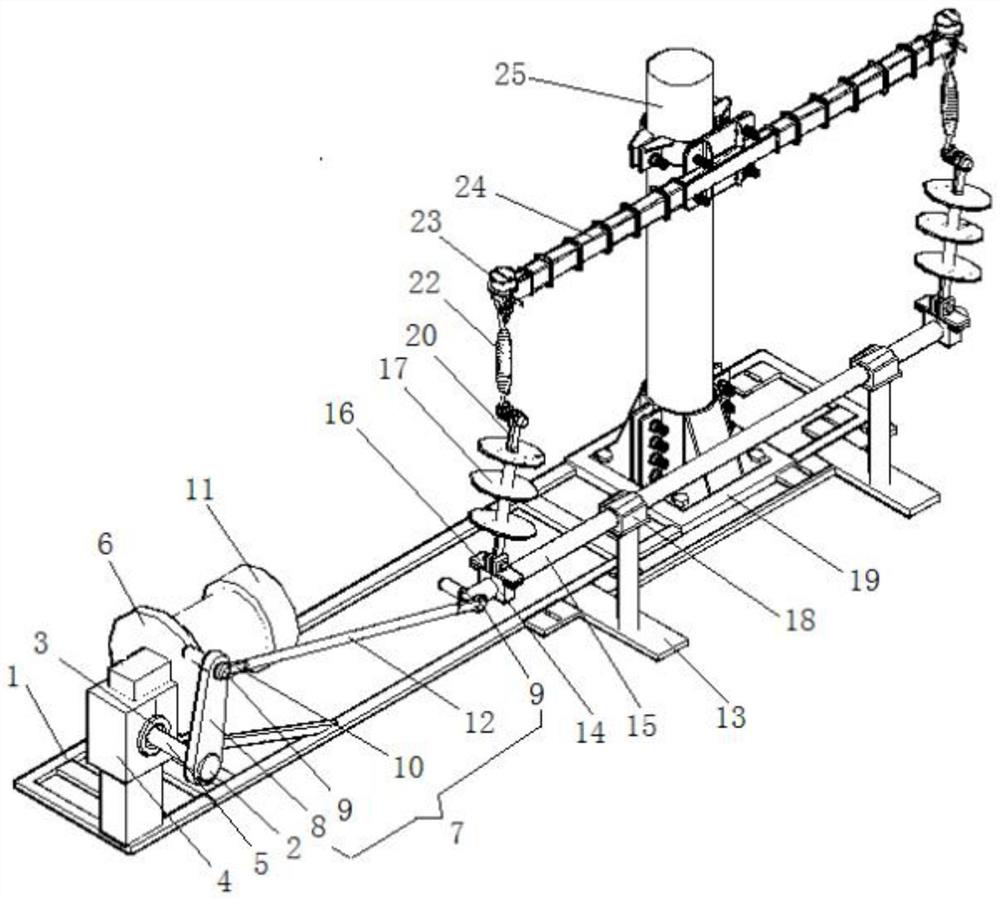

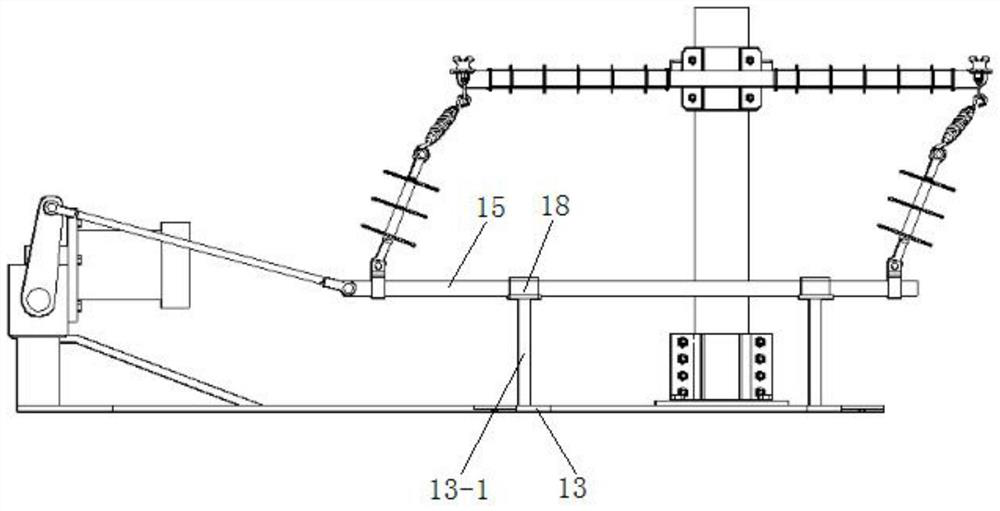

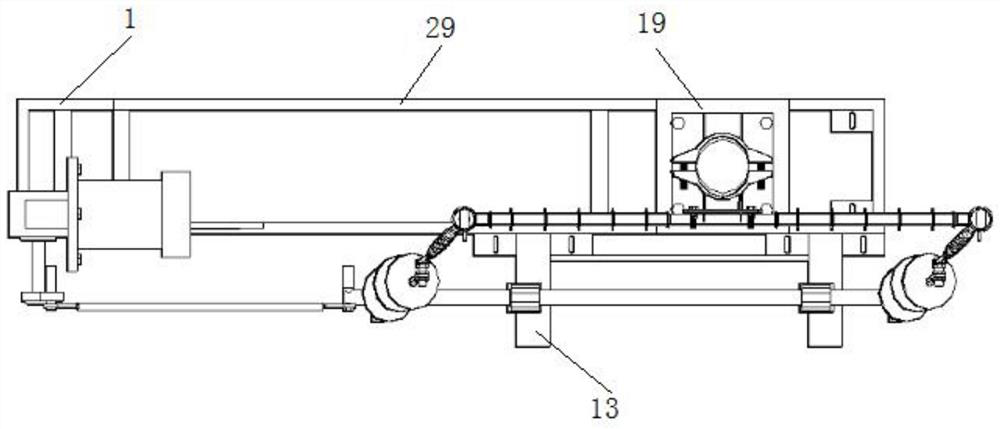

[0026] Such as Figure 1-5 As shown, a composite insulating cross-arm wind-excited vibration wear simulation test device includes a combined frame, a swing end drive mechanism, a sliding connecting rod 15 and a composite insulating cross-arm simulation assembly. The swing end driving mechanism, sliding connecting rod 15 and the composite insulating cross-arm simulation assembly are installed on the combined frame, the swing end drive mechanism is connected to the sliding link 15 through the centering crank slider mechanism 7, and the sliding link 15 is connected to At the bottom of the composite insulating cross-arm simulation component, the swing end driving mechanism drives the sliding connecting rod 15 to move horizontally through the centering crank slider mechanism 7, and the sliding connecting rod 15 drives the composite insulating The cross-arm simulation component swings back and forth. During the swing process, the measuring device on the composite insulation cross-ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com