Highland barley paper pasting device for new energy lithium iron phosphate battery

A lithium iron phosphate battery and highland barley paper technology, which is applied in battery assembly machines, secondary battery manufacturing, and electrolyte storage battery manufacturing, can solve problems such as low efficiency, low work efficiency, and difficulty in separating two adjacent sheets, so as to improve production Efficiency, the effect of saving the use of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

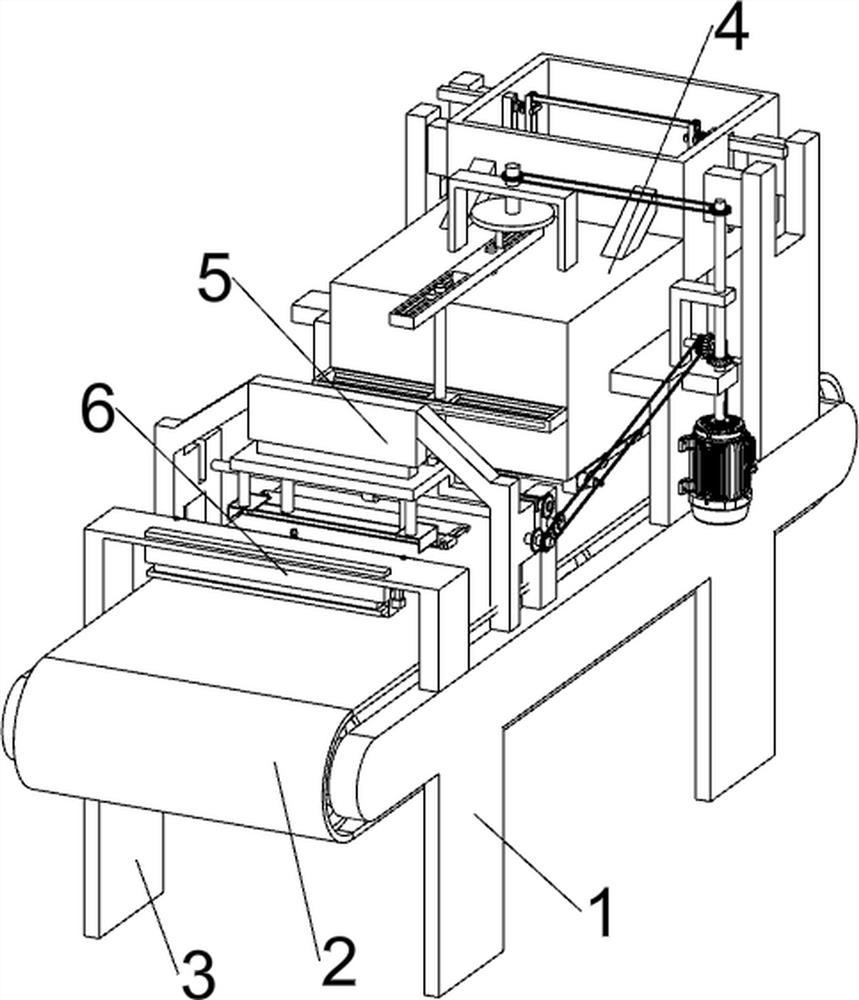

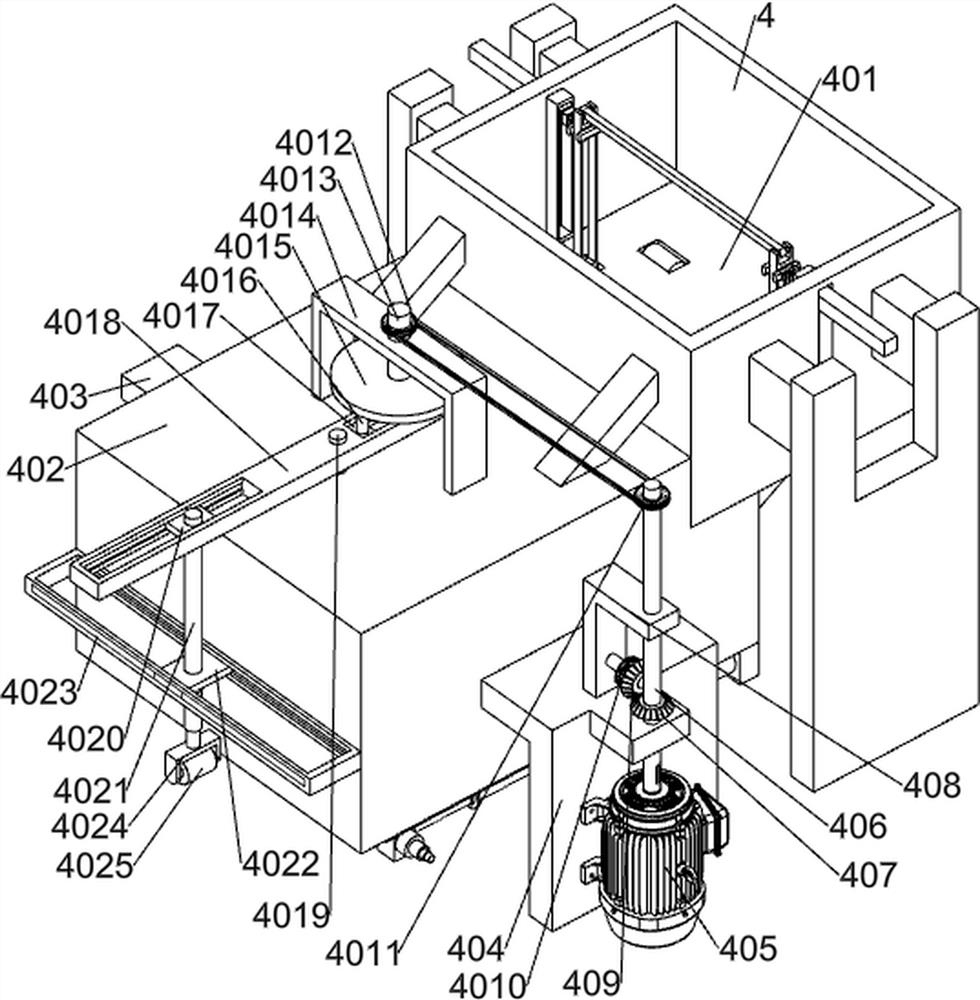

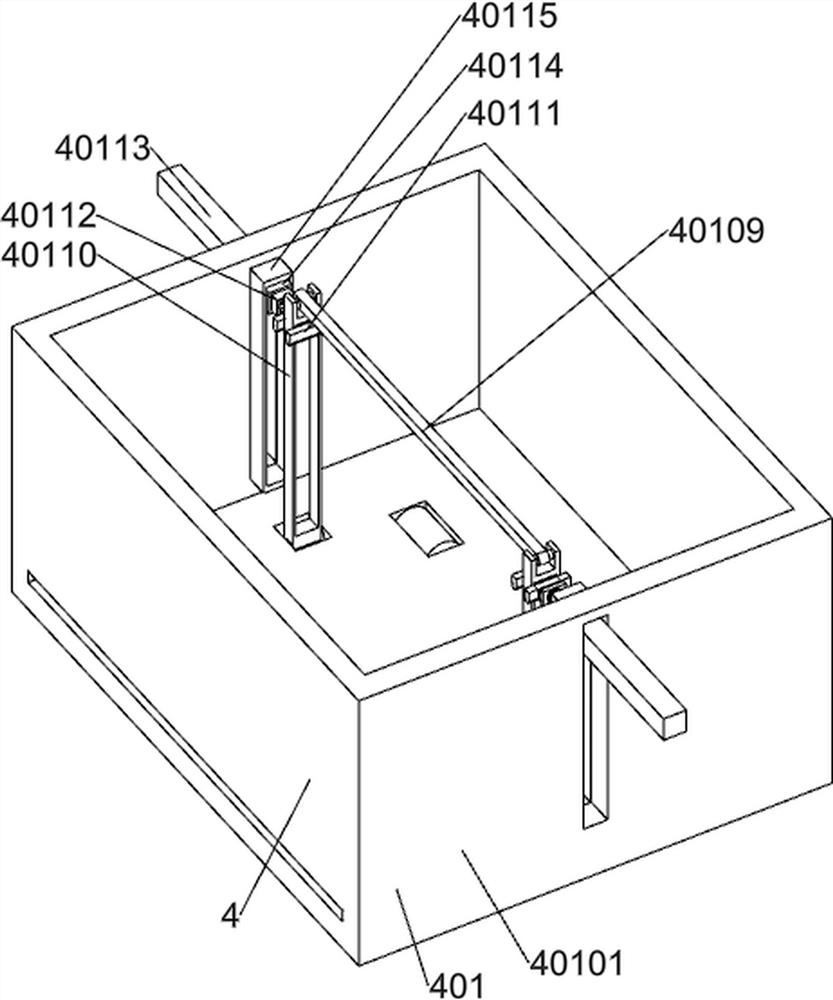

[0115] A new energy lithium iron phosphate battery barley paper pasting device, such as Figure 1-10 As shown, it includes a first installation frame plate 1, an electric transmission mechanism 2, a second installation frame plate 3, a highland barley paper output system 4, a folding and pasting system 5 and a strip paper pasting system 6; the electric transmission mechanism 2 and the second One installation frame plate 1 is connected; the second installation frame plate 3 is connected with the electric transmission mechanism 2; one side of the highland barley paper output system 4 is connected with the first installation frame plate 1, and the highland barley paper output system 4 The other side is connected with the second mounting frame plate 3; one side of the folding and pasting system 5 is connected with the first mounting frame plate 1, and the other side of the folding and pasting system 5 is connected with the second mounting frame plate 3, The folding pasting system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com