Welding device for welding nickel washer

A welding device and washer technology, which is applied in the direction of providing/exhausting protective gas, welding accessories, etc., can solve the problem of the inability to realize the free shrinkage of the nickel washer weld seam, and reduce the temperature, the oxidation probability, and the welding seam overheating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

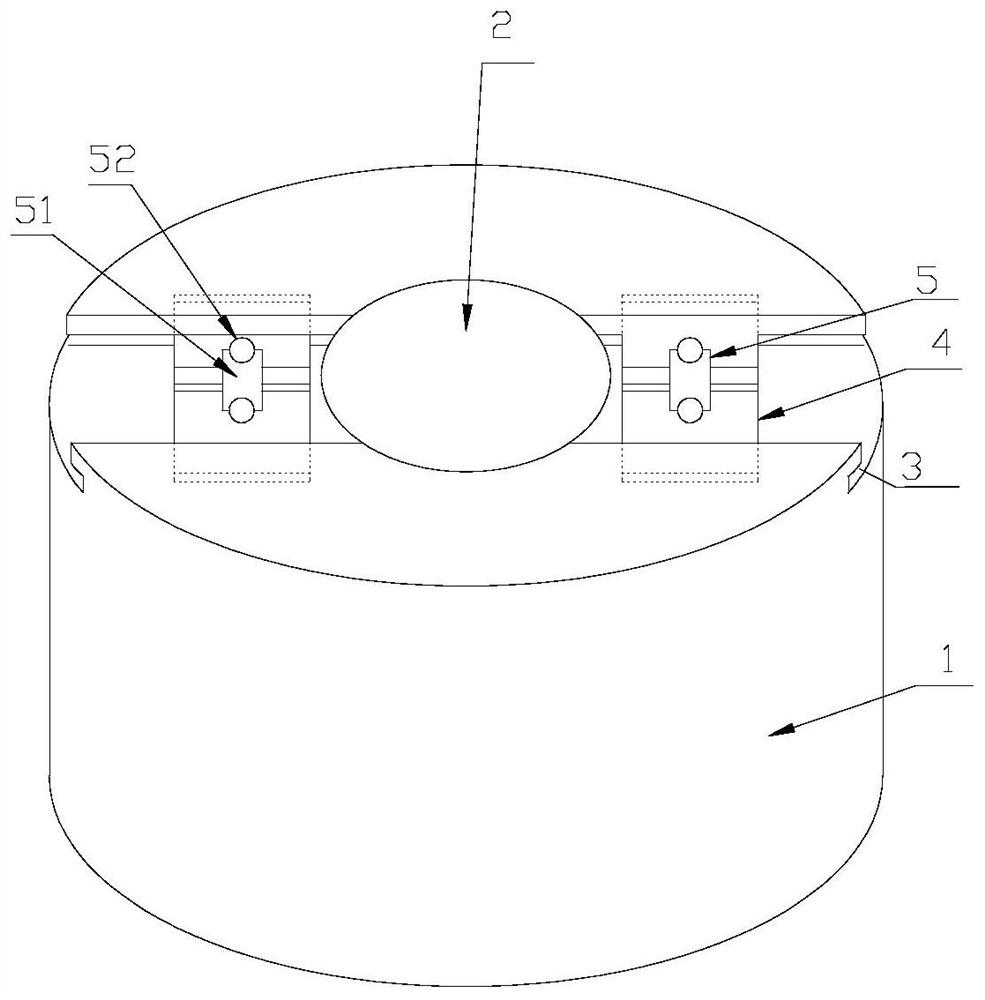

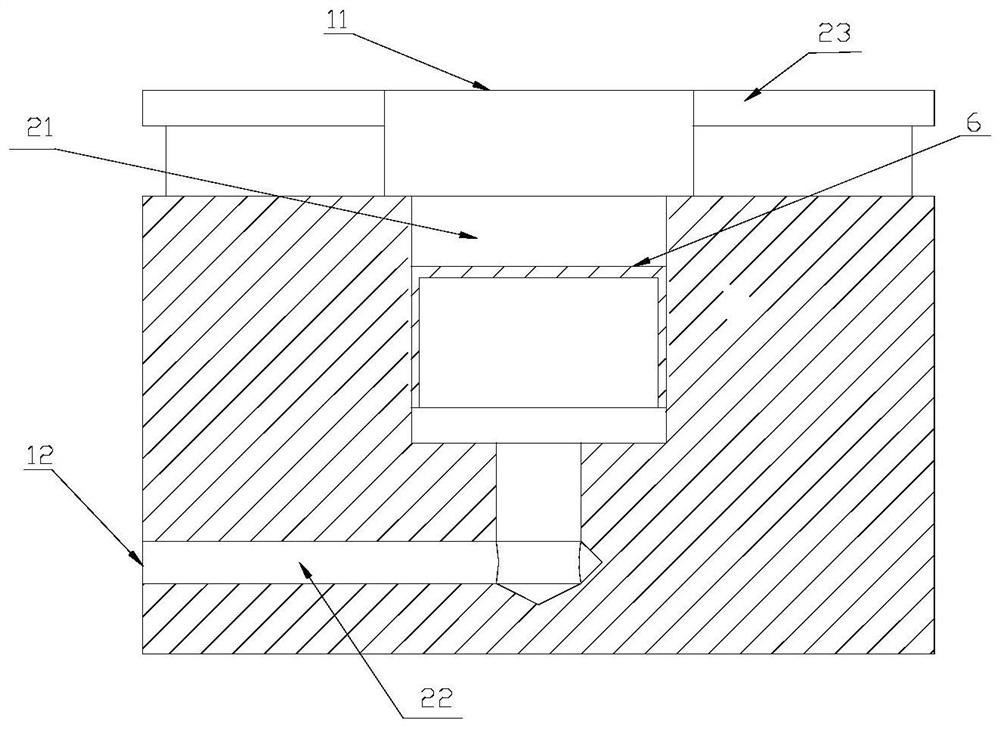

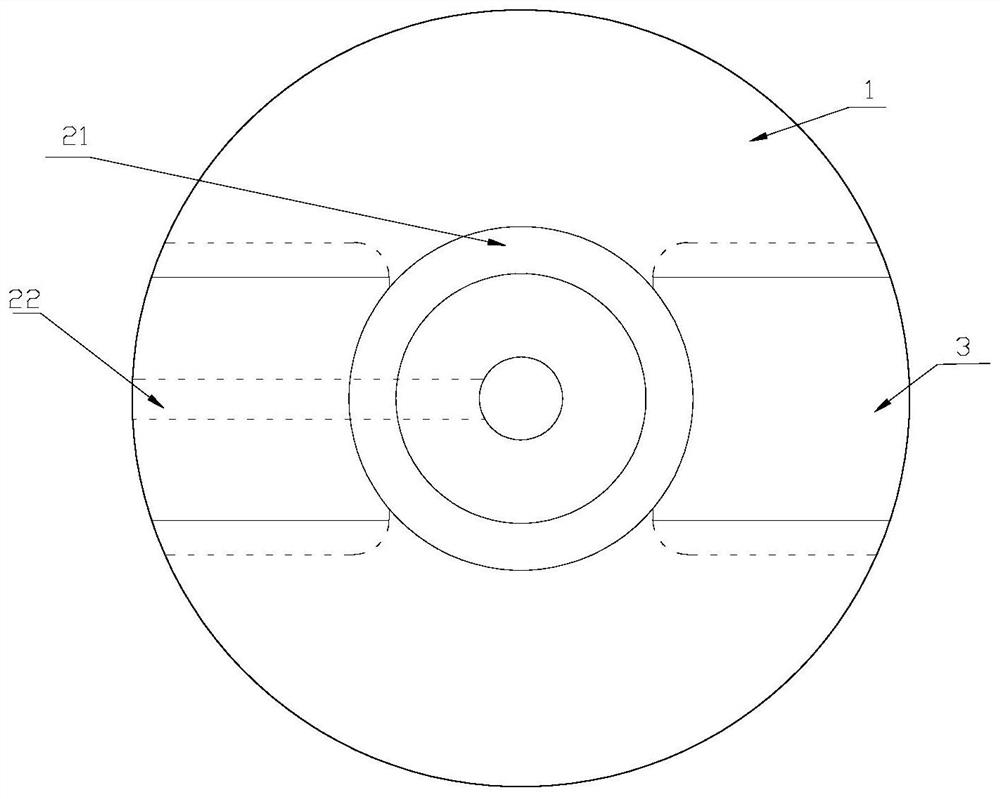

[0031] Such as figure 1 As shown, the present invention provides a welding device for welding nickel gaskets. The welding device is made of red copper and includes: a base 1 , a channel 2 , a chute 3 , a slider 4 and a fixing device 5 . The base 1 is a cylindrical structure, and a channel 2 leading to an inert gas is provided downwards at the center of the top surface of the base 1, which runs through the inside of the base 1 and forms a first opening 11 and a The second opening 12 . On the top surface of the base 1 , on the left and right sides of the first opening 11 , there are symmetrically downwardly provided slide grooves 3 , and the slide grooves 3 have an inverted T-shaped structure. A slider 4 matched with the chute 3 is slidably connected in each chute 3 , and each slider 4 can move left and right along the corresponding chute 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com