Bridge or house building support friction part convenient to rotate or slide and preparation method thereof

A technology for friction parts and construction, which is applied in bridge construction, architecture, bridges, etc., can solve the problems of restricting the use effect of bearings and increasing costs, and achieve the effects of ensuring cladding quality, reducing production costs, and ensuring spherical radians

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

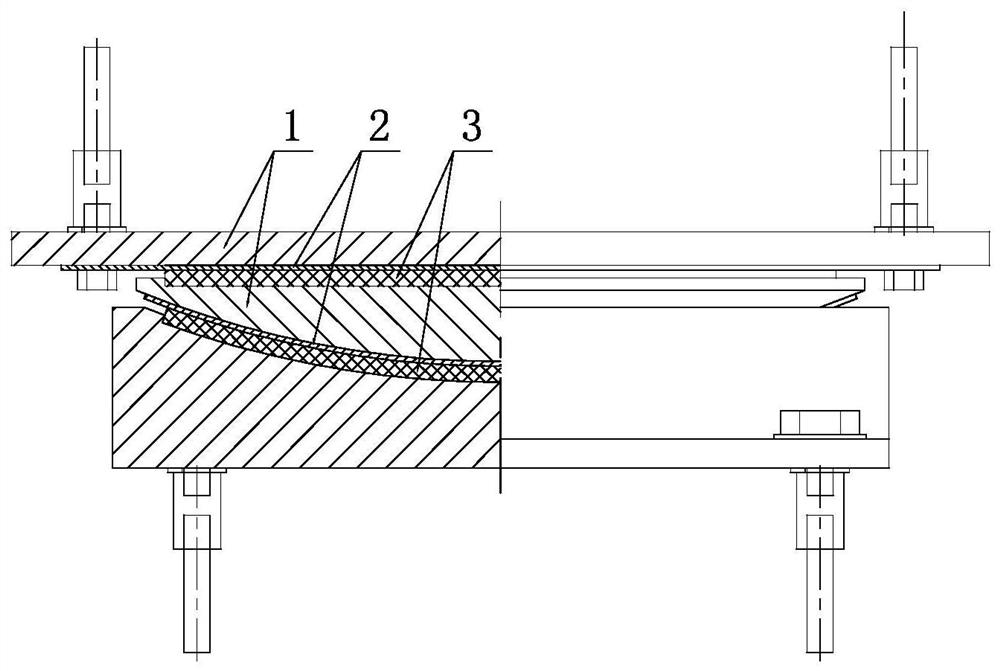

[0043] The overall structure of this embodiment is as figure 1 As shown, it includes components such as an upper bearing plate, a lower bearing plate, and a spherical crown plate, and an organic material slide plate 3 is arranged between the spherical crown plate and the upper bearing plate and between the spherical crown plate and the lower bearing plate , the friction surface opposite to the organic material slide plate 3 includes a substrate 1 and an anti-rust and wear-resistant layer 2, and the anti-rust and wear-resistant layer 2 is arranged on the outer surface of the base 2 by laser cladding. The surface of the base body 1 of the upper support plate opposite to the organic material slide plate 3 is laminated with a flat anti-rust and wear-resistant layer by laser cladding, and the surface of the base body 1 of the spherical crown plate opposite to the organic material slide plate 3 is laser clad. The method is compounded with an anti-rust and wear-resistant layer with a...

Embodiment 2

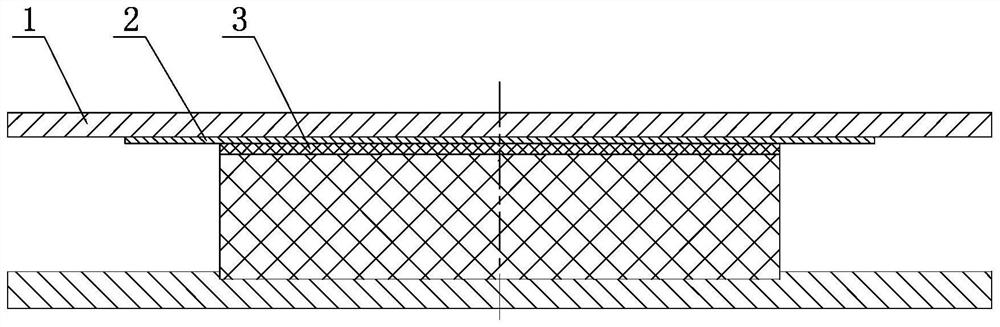

[0060] The overall structure of this embodiment is as figure 2 As shown, it includes components such as an upper steel plate, a lower steel plate, and an intermediate plate. An organic material slide plate 3 is arranged on the upper surface of the intermediate plate. The grinding layer 2 and the anti-rust and wear-resistant layer 2 are arranged on the outer surface of the substrate 2 by means of laser cladding.

[0061] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

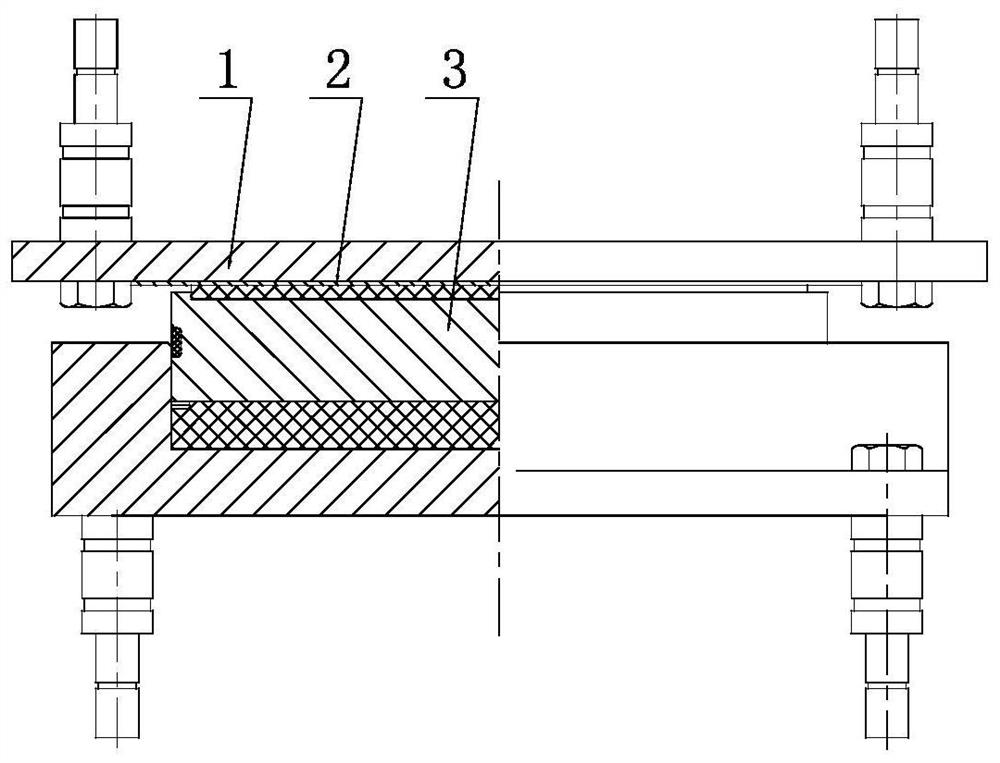

[0063] The overall structure of this embodiment is as image 3 As shown, it includes components such as an upper support plate, a lower support plate, and an intermediate plate. An organic material slide plate 3 is arranged on the upper surface of the intermediate plate, and the friction surface of the lower part of the upper support plate opposite to the organic material slide plate 3 includes Substrate 1, anti-rust and wear-resistant layer 2, the anti-rust and wear-resistant layer 2 is arranged on the outer surface of the substrate 2 by laser cladding.

[0064] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com