Testing, adjusting and sealing examining integrated device for separate injection well

A separate injection well, measurement and adjustment technology, applied in the direction of measurement, fluid production, sealing/isolation, etc., can solve the problems that the packer does not have the function of seal inspection and pressure measurement, etc., to achieve high isolation sealing pressure and high operating efficiency , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

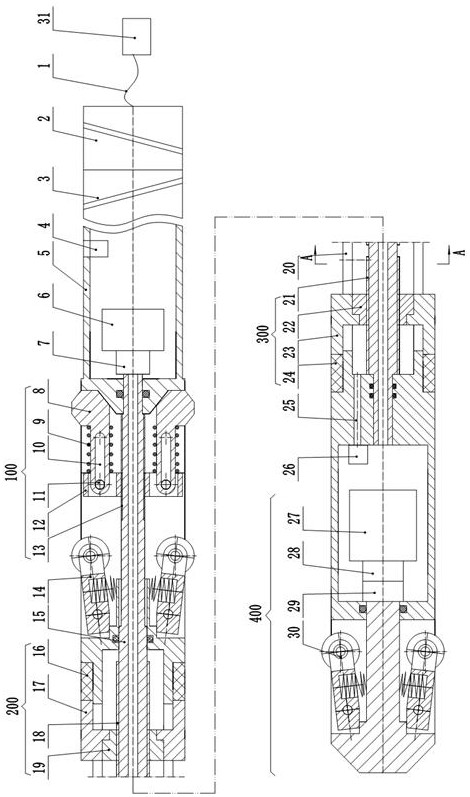

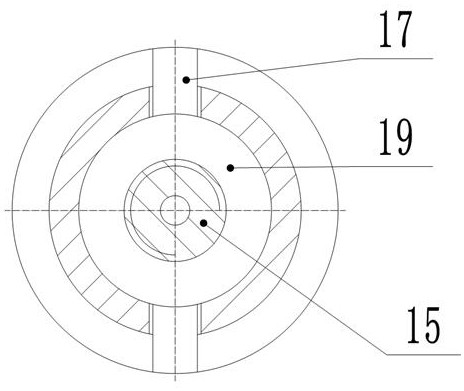

[0031] The "upper" and "lower" mentioned in terms of positional relationship in this specification and the claims are described in terms of the positional relationship of the state of the device going down the well. When describing the relationship between inside and outside or inside and outside of the pipe, the place with the small radial radius is the inside or inside, and the place with the large radius is the outside. In each accompanying drawing, there are sealed places according to the drawings, and will not be repeated in the following descriptions.

[0032] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

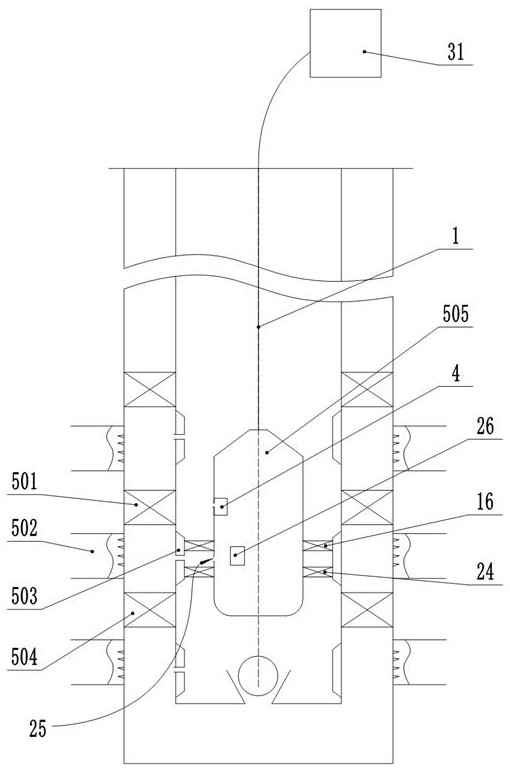

[0033] See attached figure 2 , Injection well testing and sealing integration device, including downhole injection string and testing and sealing system.

[0034] The downhole injection string ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com