Recyclable self-repairing gel-state electrolyte as well as preparation method and application thereof

A technology of gel state and electrolyte, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, sustainable manufacturing/processing, etc., can solve the problems of high environmental requirements, harsh environments, single performance, etc. The effect of safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

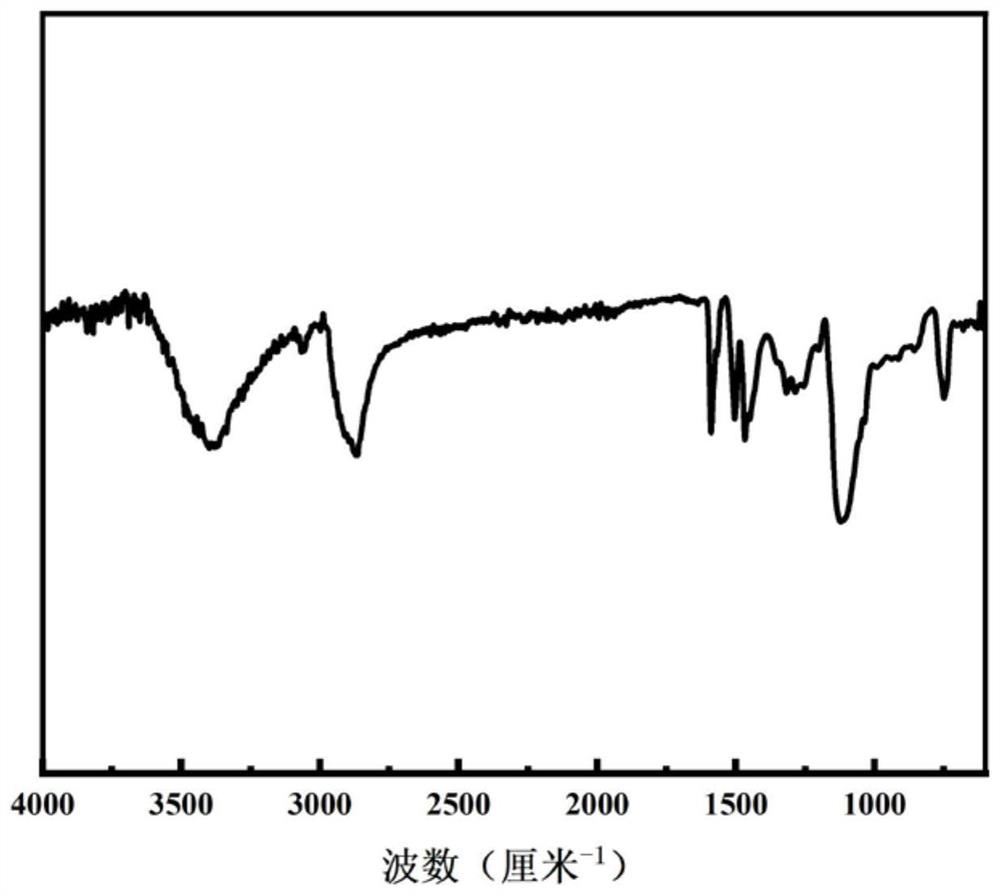

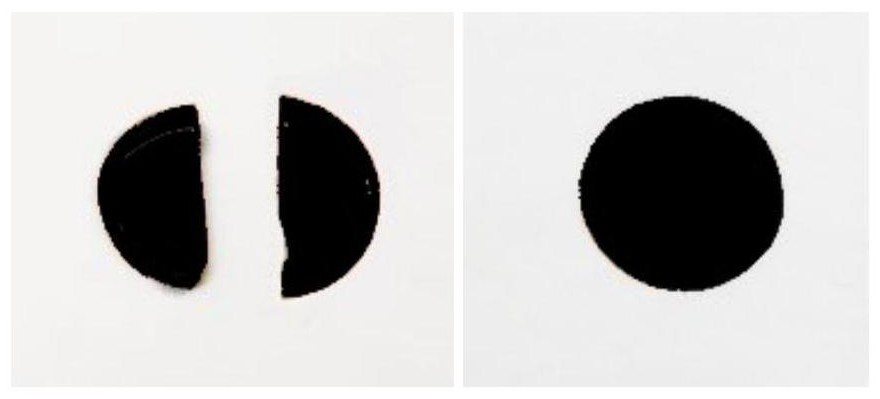

Method used

Image

Examples

Embodiment 1

[0028] (1) Stir and mix DGEBA and PEGDGE with a molar ratio of 1:1.

[0029] (2) Add PEG200 and 1:2 2-AFD at a mass ratio of 1:2 to epoxy resin to the solution obtained in (1), and stir and mix at 90°C.

[0030] (3) Cast the solution obtained in (1) on a polytetrafluoroethylene plate, place gaskets around it, place another polytetrafluoroethylene plate on the gasket to form a sandwich structure, and place it in a blast oven , heating at 130°C for 2 hours and 150°C for 2 hours to prepare a film, soak the film in deionized water for three days, and dry to obtain an unactivated electrolyte.

[0031] (4) Transfer the film to the glove box, soak the electrolyte (the electrolyte is a mixed solution of lithium hexafluorophosphate mixed with dimethyl carbonate, ethyl methyl carbonate and ethylene carbonate, and its mass ratio is dimethyl carbonate: ethyl methyl carbonate : Ethylene carbonate = 1:1:1, concentration 1M) for 24 hours. The final result is a gel-state polymer electrolyte...

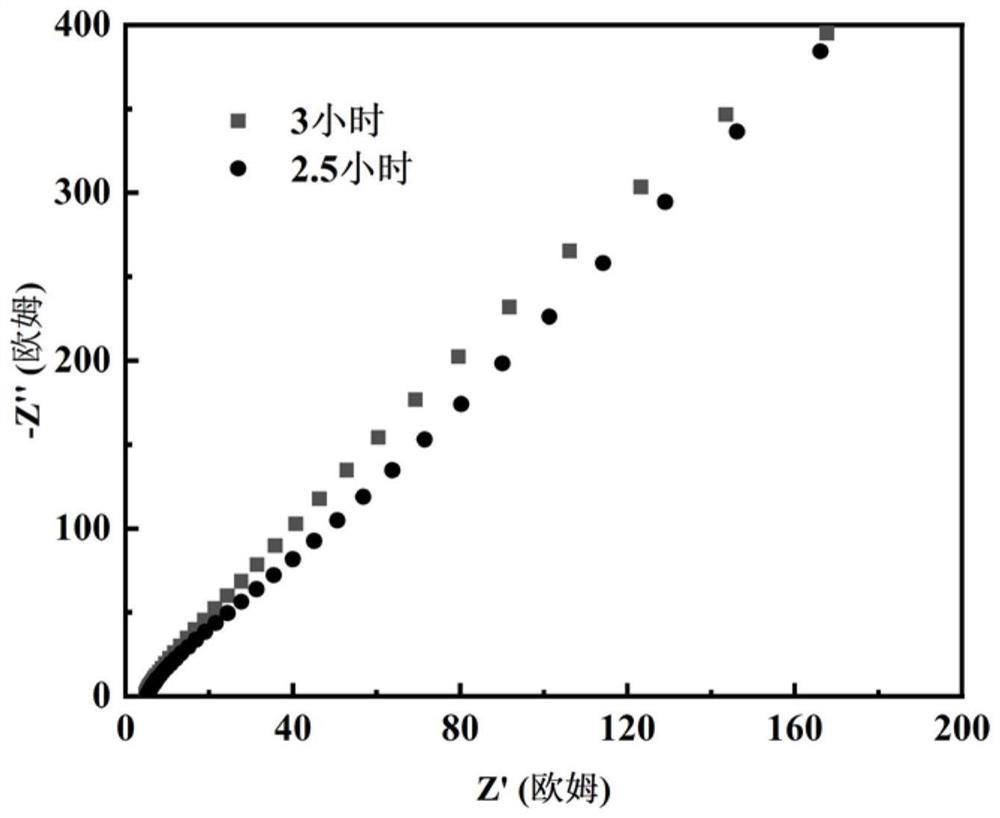

Embodiment 2

[0033] (1) Stir and mix DGEBA and PEGDGE with a molar ratio of 1:9.

[0034] (2) Add PEG200 with a mass ratio of 1:2 to epoxy resin and 2-AFD with a mass ratio of 2:1 to the solution obtained in (1), and stir and mix at 90°C.

[0035] (3) Cast the solution obtained in (1) on a polytetrafluoroethylene plate, place gaskets around it, place another polytetrafluoroethylene plate on the gasket to form a sandwich structure, and place it in a blast oven , heating at 130°C for 2 hours and 150°C for 2 hours to prepare a film, soak the film in deionized water for three days, and dry to obtain an unactivated electrolyte.

[0036] (4) Transfer the film to the glove box, soak the electrolyte (the electrolyte is a mixed solution of lithium hexafluorophosphate mixed with dimethyl carbonate, ethyl methyl carbonate and ethylene carbonate, and its mass ratio is dimethyl carbonate: ethyl methyl carbonate : Ethylene carbonate = 1:1:1, concentration 1M) for 24 hours. The final result is a gel-stat...

Embodiment 3

[0038] (1) Stir and mix DGEBA and PEGDGE with a molar ratio of 1:9.

[0039] (2) Add PEG200 and 2:1 2-AFD at a mass ratio of 2:1 to epoxy resin to the solution obtained in (1), and stir and mix at 90°C.

[0040] (3) Cast the solution obtained in (1) on a polytetrafluoroethylene plate, place gaskets around it, place another polytetrafluoroethylene plate on the gasket to form a sandwich structure, and place it in a blast oven , heating at 130°C for 2 hours and 150°C for 2 hours to prepare a film, soak the film in deionized water for three days, and dry to obtain an unactivated electrolyte.

[0041] (4) Transfer the film to the glove box, soak the electrolyte (the electrolyte is a mixed solution of lithium hexafluorophosphate mixed with dimethyl carbonate, ethyl methyl carbonate and ethylene carbonate, and its mass ratio is dimethyl carbonate: ethyl methyl carbonate : Ethylene carbonate = 1:1:1, concentration 1M) for 24 hours. The final result is a gel-state polymer electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com