Motor transmission machining assembly

A technology of motor drive and assembly, applied in electric components, metal processing equipment, electromechanical devices, etc., can solve the problems of multi-use space, long motor length, troublesome assembly of transmission belts, etc., to save volume, reduce length, and improve work efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

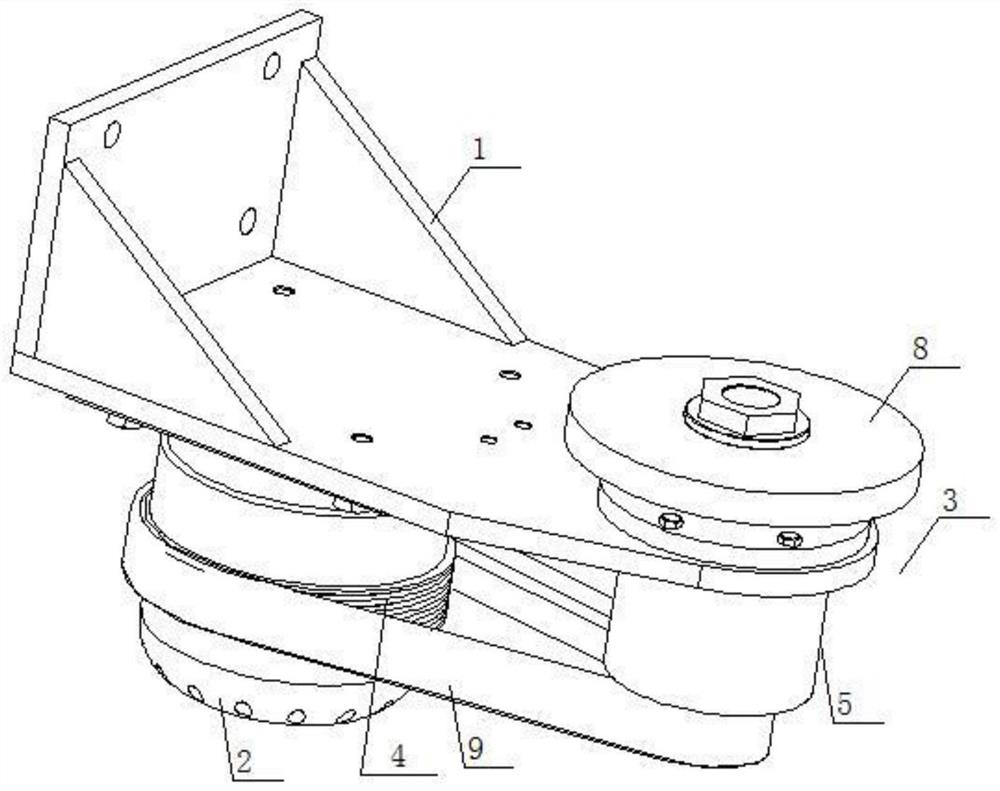

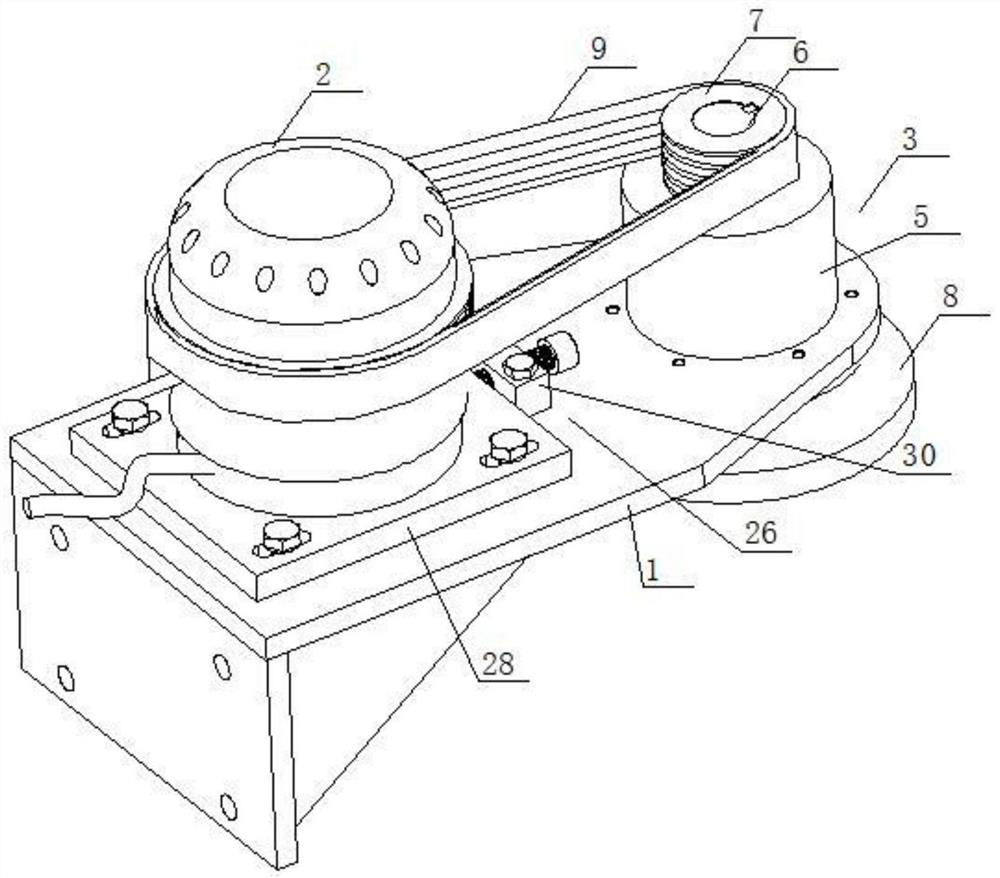

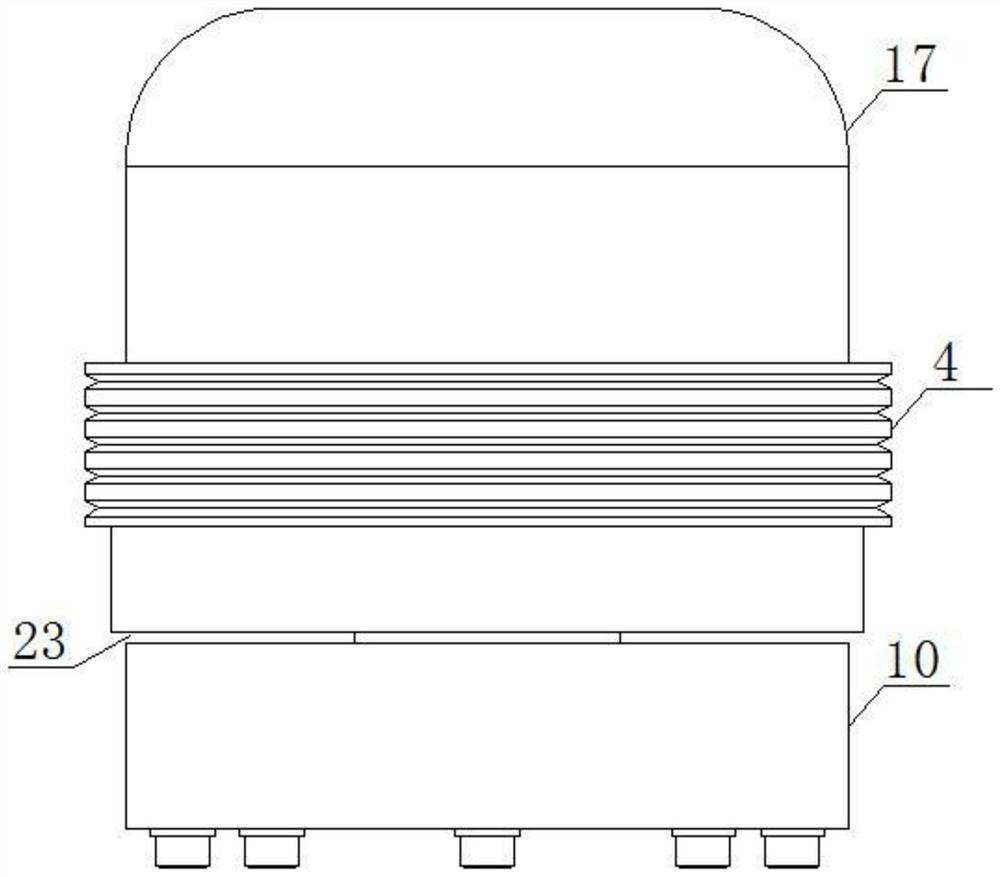

[0023] refer to Figure 1-Figure 8 , a motor transmission processing assembly, comprising a support 1, an outer rotor motor 2 correspondingly installed at both ends of the support 1, a driven grinding device 3, a driving pulley 4 is installed on the outer wall of the outer rotor motor 2, and the driven grinding The cutting device 3 includes a bearing seat 5 fixed on the support 1, a driven shaft 6 connected to the first bearing installed in the bearing seat 5, a driven pulley 7 installed at both ends of the driven shaft 6, and a grinding wheel. Part 8, a drive belt 9 is installed between the driving pulley 4 and the driven pulley 7, the outer rotor 17 drives the driving pulley 4 to rotate, the driving pulley 4 drives the driven pulley 7 and the driven shaft 6 to rotate through the drive belt 9, and is installed on the driven The grinding part 8 at the other end of the shaft 6, such as a grinding wheel, a cutter, etc., rotates, and the grinding part 8 performs grinding, cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com