Energy-saving sweeping brush convenient to replace and connecting assembly thereof

A technology for connecting components and sweeping brushes, which is applied in the direction of cleaning carpets, floors, and manual sweeping machines. It can solve problems such as low efficiency and labor-intensive, and achieve the effects of reducing costs, improving efficiency, and stabilizing connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

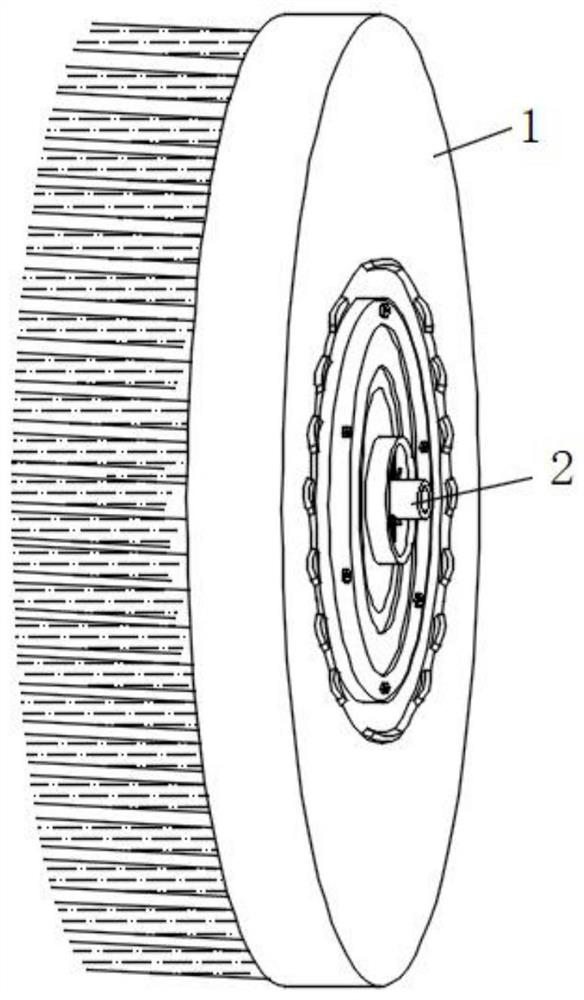

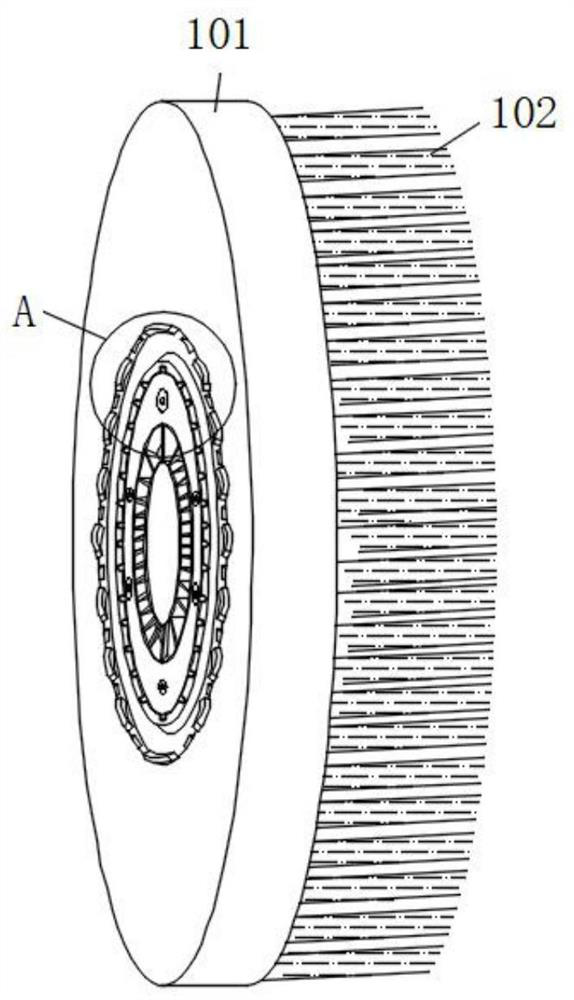

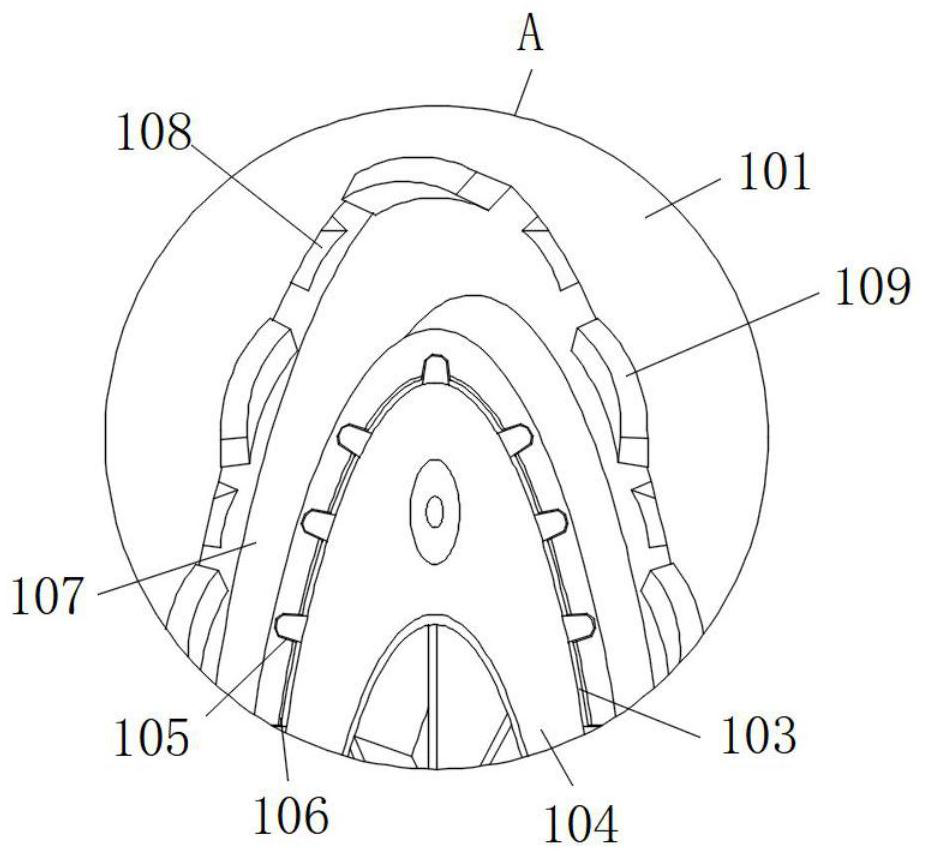

[0034] refer to Figure 1-7 , an energy-saving sweeping brush and its connection assembly that are easy to replace, including a sweeping brush body 1 and a connection assembly 1, the sweeping brush body 1 includes a flocking plate 101, bristles 102 are fixed on one side of the flocking plate 101, and both sides of the center of the flocking plate 101 A mounting hole 103 is opened through the mounting hole 103, and a connecting component 2 104 is clamped in the mounting hole 103. The connecting component 2 104 includes a mounting plate 1041, and the end of the mounting plate 1041 facing away from the bristles 102 is also provided with an annular groove 1044. The inner wall of the annular groove 1044 is fixed. Connected with a spacer 1045, the spacer 1045 divides the annular groove 1044 into a plurality of clamping grooves 1046, and a tapered hole 1047 is opened on both sides of the center of the mounting plate 1041, and a cylindrical groove is formed on the extension of the end ...

Embodiment 2

[0037] Such as image 3 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the mounting plate 1041 is connected in sliding contact with the inner wall of the mounting hole 103, the outer wall of the mounting plate 1041 is fixed with locking teeth 1042, and the inner wall of the mounting hole 103 is also provided with tooth grooves 105. And latching tooth 1042 is all placed in the draw-in groove, and mounting disc 1041 outer wall also offers cylindrical groove 1, and cylinder 1 inwall is all fixedly installed with electromagnet 1043, and the mounting hole 103 inwall is also fixed with adsorption iron ring 106.

[0038] A plurality of locking teeth 1042 are provided and evenly distributed on the outer wall of the mounting plate 1041 , and the locking teeth 1042 are all slidingly connected in the slots 105 .

[0039] The number of cylindrical slots is one less than that of the locking teeth 1042 and are evenly arranged on the outer wall of the mou...

Embodiment 3

[0042] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are a plurality of bristles 102 that are evenly distributed in bundles at the middle of one end of the hair-planting plate 101 and at the extension position.

[0043] In this embodiment, a plurality of bristles 102 are arranged and evenly distributed in bundles in the middle and extension of one end of the hair-planting plate 101, thereby increasing the cleaning range of the sweeping brush body 1 and providing a certain guarantee for rapid cleaning of the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com